Numerical control gate boring-milling machine high-speed main spindle clamp tool resetting mechanism

A high-speed spindle and reset mechanism technology, used in clamping, positioning devices, metal processing mechanical parts, etc., can solve the problem of large force on the thrust bearing at the end of the spindle, and achieve the effect of high-speed heavy cutting and reducing force load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

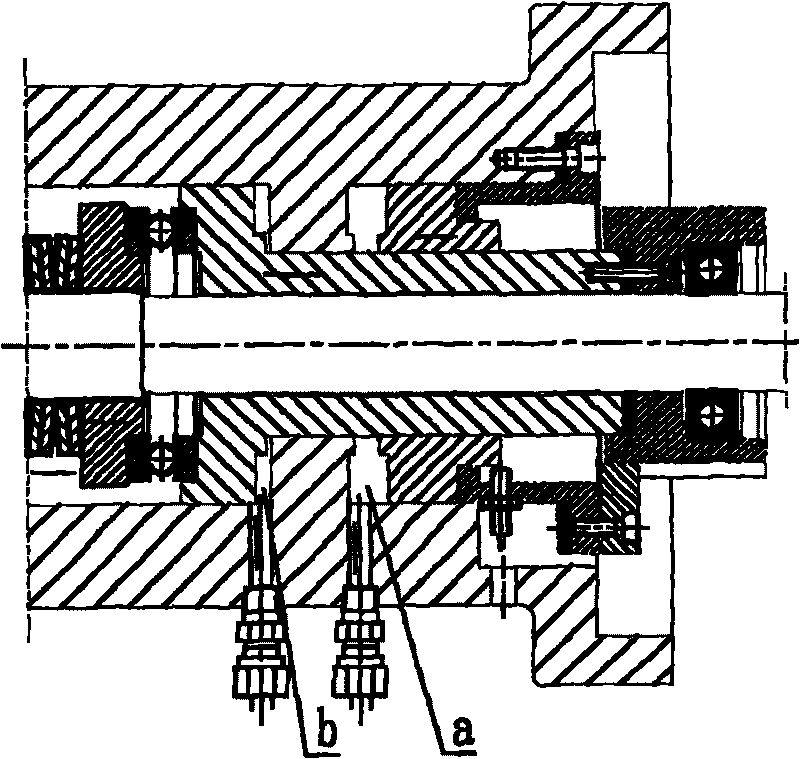

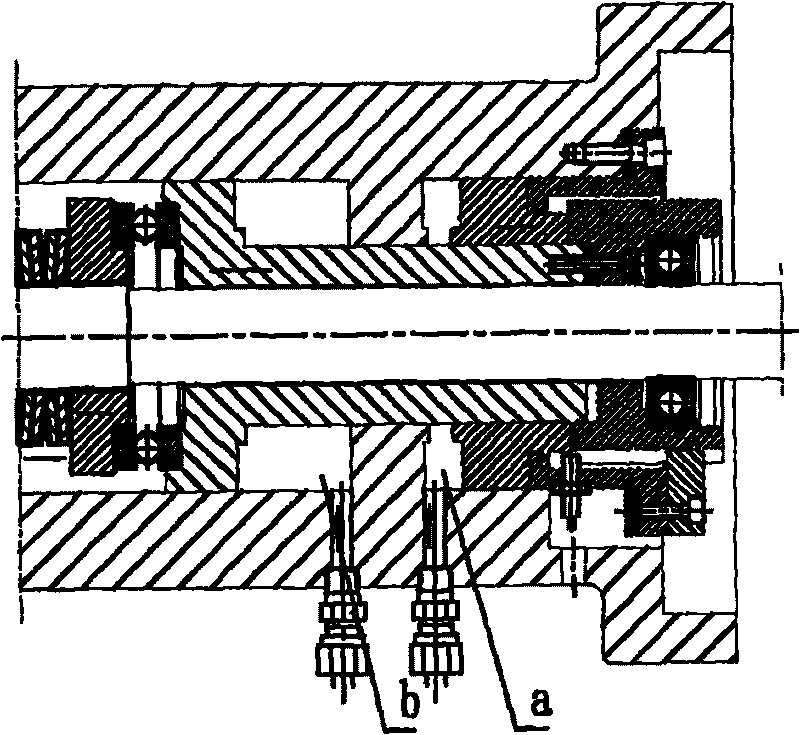

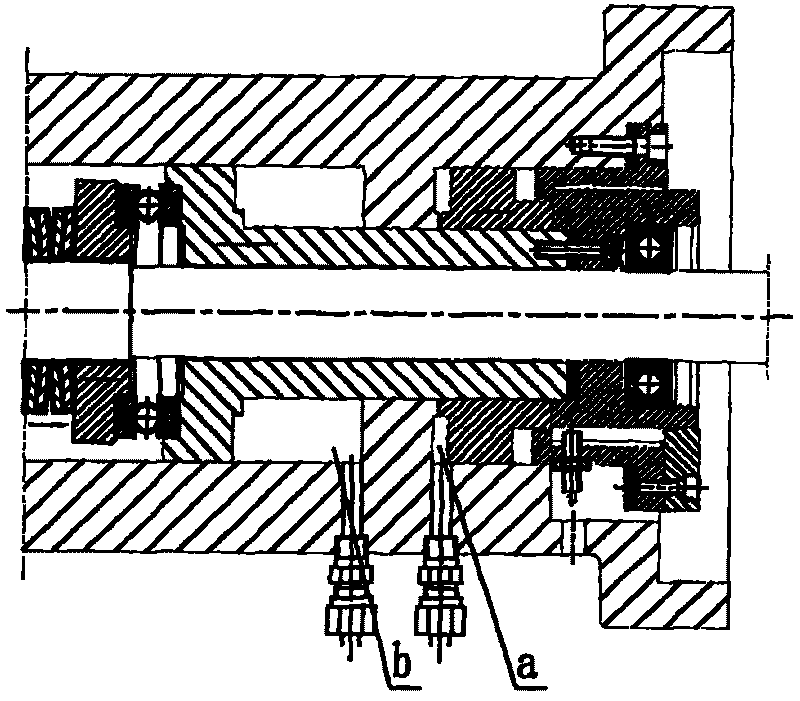

[0014] Below in conjunction with accompanying drawing, the utility model is further described:

[0015] attached by Figure 4 - attached Image 6 As shown, the high-speed spindle tool clamping reset mechanism of the CNC gantry boring and milling machine is improved on the basis of the original mechanism, and the oil chamber c for realizing the reset action is added, so that there is a tool clamping reset gap X between the push rod 8 and the spindle sleeve 7, The value range of X is between 1mm and 3mm, which is sufficient to ensure that the push rod 8 is separated from the main shaft sleeve 7, and if it is too large, the movement stroke of the tool release device will be increased. Current institutions such as Figure 4 As shown, it mainly includes oil cylinder 1, new piston rod 2 and piston 3, the left end of oil cylinder 1 is fixed with connecting sleeve 5, and the connecting sleeve 5 is fixed on the headstock of the ram; the inner steps of connecting sleeve 5, oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com