Reinforcement cage for cast-in-place pile with oversized tip

A technology of steel skeleton and cast-in-place piles, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of inability to increase the diameter of the pile bottom and the difficulty of guaranteeing the size of the pile bottom, so as to improve the overall seismic capacity and load bearing capacity. The effect of simple force and mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

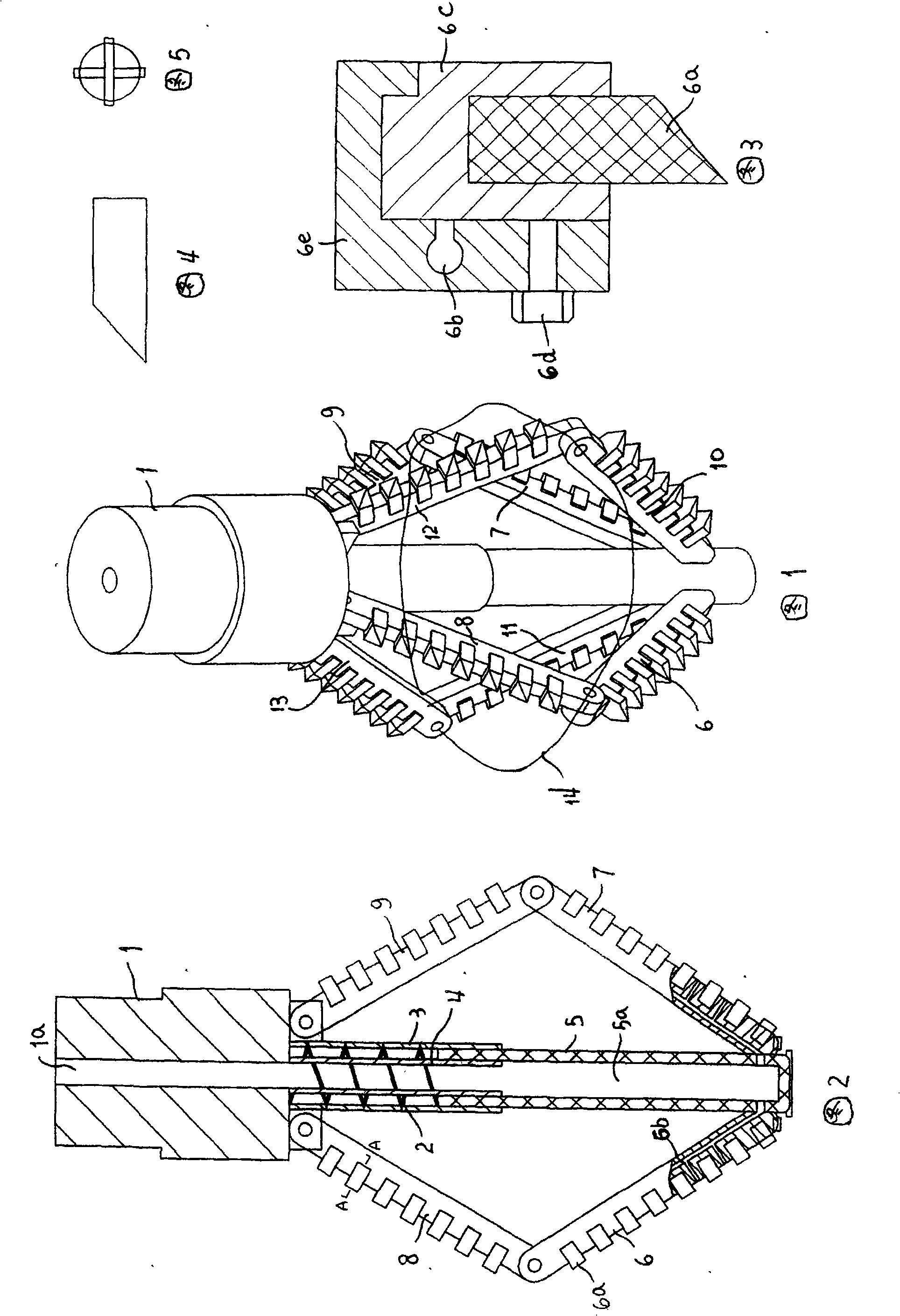

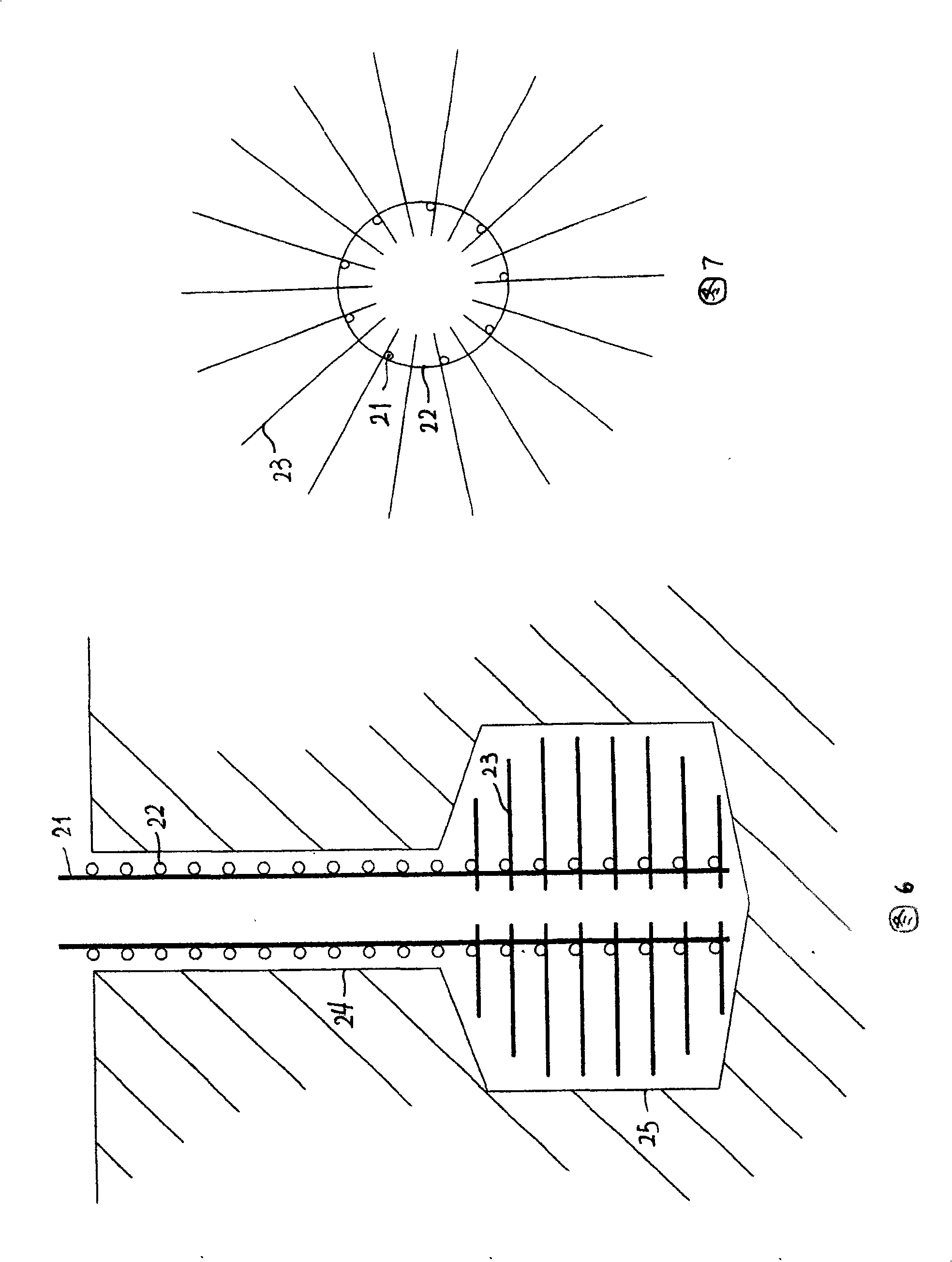

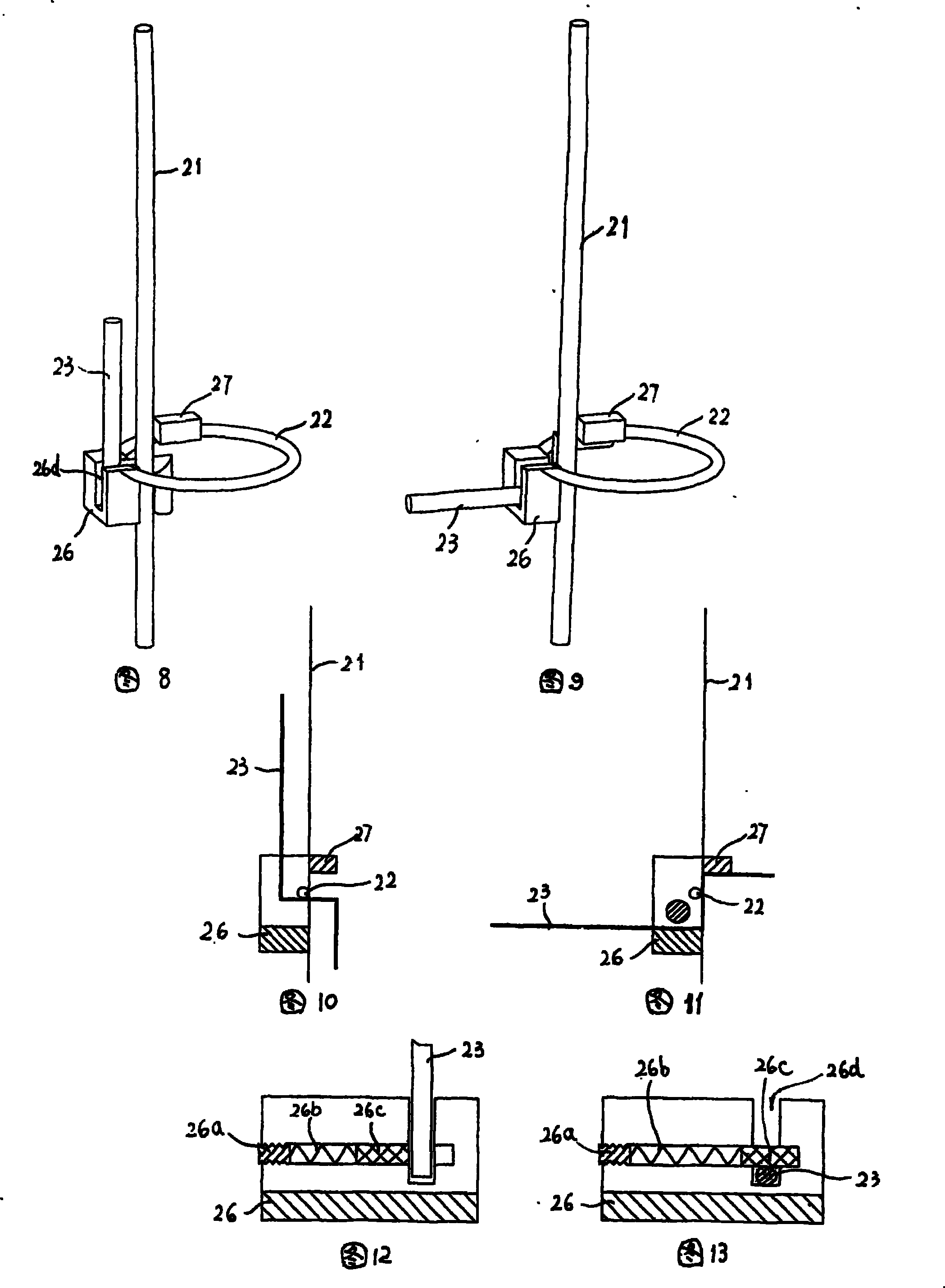

[0056] A method for constructing cast-in-situ piles with super-diameter reaming at the ends of machine drills, characterized in that: the following steps are carried out:

[0057] a) Use conventional pile drilling rigs to construct to the predetermined reaming depth;

[0058] b) Replace the reaming drill bit to carry out the construction of the reaming section, so that the bottom of the pile forms a cylinder or cone with a diameter of 2 to 4 times the diameter of the pile body;

[0059] c) Use gravity or external force to lower the reinforcement cage;

[0060] d) Pouring concrete to form cast-in-place piles.

[0061] The detailed construction steps of the present invention are as follows:

[0062] The construction process is leveling the site → laying the pile position line and re-testing → drilling rig in place → correcting the centering and sag of the drill pipe → drilling → slag removal → soil removal → placing the steel hole protection pipe at the orifice → measuring the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com