Duplex metal phosphide catalyst for selective hydrogenation and olefin hydrocarbon removal as well as preparation method thereof

A catalyst and phosphide technology, applied in the field of solid catalyst and its preparation for selective hydrogenation of a small amount of olefins in aromatics, achieving good application prospects and high selective hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of TiO by coprecipitation method 2 -Ni 2 P catalyst precursor. 3.90 grams of nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) dissolved in 15 mL of deionized water, 2.70 g of titanium tetrachloride (TiCl 4 ) was dissolved in 100mL ethanol, and an appropriate amount of TiCl 4 Add the ethanol solution into the nickel nitrate solution and stir well. Added TiCl 4 The amount of ethanol solution is determined according to the total Ti / Ni molar ratio. Then 1.77 grams of diamine hydrogen phosphate ((NH 4 ) 2 HPO 4 ) was dissolved in 10mL deionized water and added dropwise to the above TiCl-containing 4 In the nickel nitrate solution in ethanol solution, a precipitate is formed. The resulting mixture was evaporated to dryness with stirring, the slurry was dried at 120° C. for 12 hours, and then calcined at 500° C. for 3 hours to obtain a catalyst precursor.

Embodiment 2

[0018] Preparation of CeO by impregnation method 2 -Ni 2 P catalyst precursor.

[0019] First, unsupported Ni was prepared by co-precipitation method 2 P catalyst precursor. Weigh 3.90 grams of nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) was dissolved in 15mL deionized water, 1.77 grams of diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) was dissolved in 10 mL of deionized water. Then the diammonium hydrogen phosphate solution was added dropwise to the nickel nitrate solution to form a precipitate. The water was evaporated to dryness, and the solid product was dried at 120°C for 12 hours, and then calcined at 500°C for 3 hours to obtain Ni 2 P precursor.

[0020] Ni will be produced 2 After the P precursor is finely ground, it is added to the metered Ce(NO 3 ) 3 ·6H 2 O aqueous solution (the concentration is determined by the catalyst Ce / Ni molar ratio), impregnated for 12 hours, then dried at 120°C for 12 hours, and calcined at 500°C for 3 hours to obtain CeO-containi...

Embodiment 3

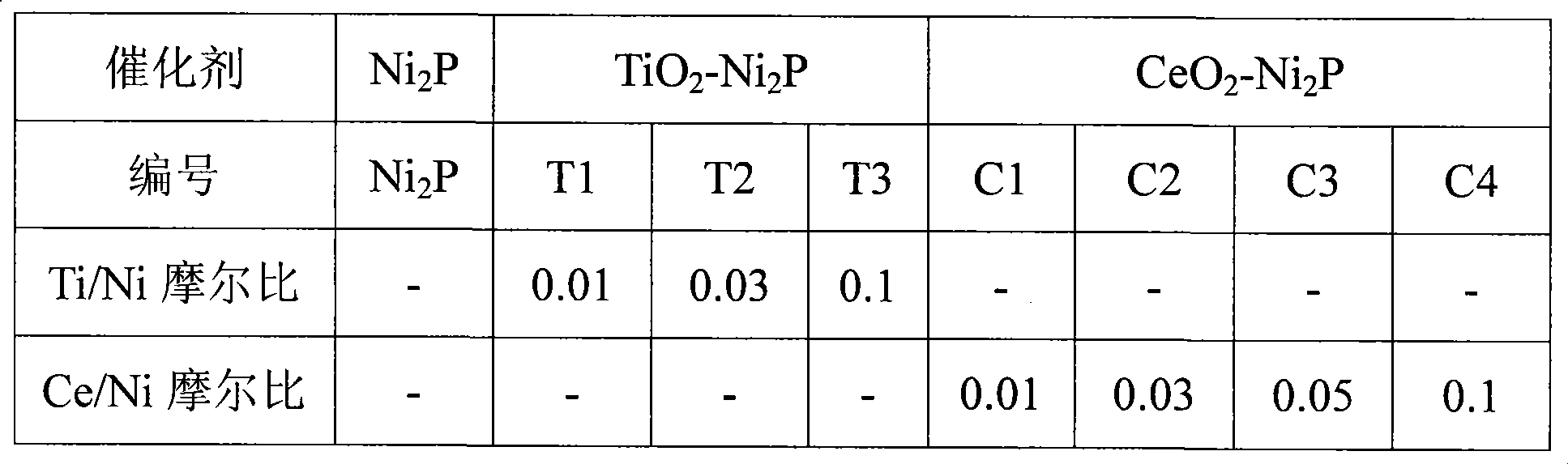

[0022] Weigh 0.5 g of the catalyst precursor in Example 1 or 2, and put it into a fixed-bed reactor with an inner diameter of 8 mm. In a hydrogen atmosphere, raise the temperature from room temperature to 400°C at a rate of 2°C / min, then raise it to 500°C at a rate of 1°C / min, keep it for 2 hours, and then cool down to the reaction temperature naturally to prepare a bimetallic phosphide catalyst. The gas flow rate is 200mL / min, and the pressure is 1MPa. Table 1 lists the catalysts prepared by the method of the present invention.

[0023] Table 1 Catalyst prepared by the present invention

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com