Oil refining chemical component tracing method

A component tracking, refining and chemical technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., to achieve the effect of fine management and accurate understanding of logistics conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

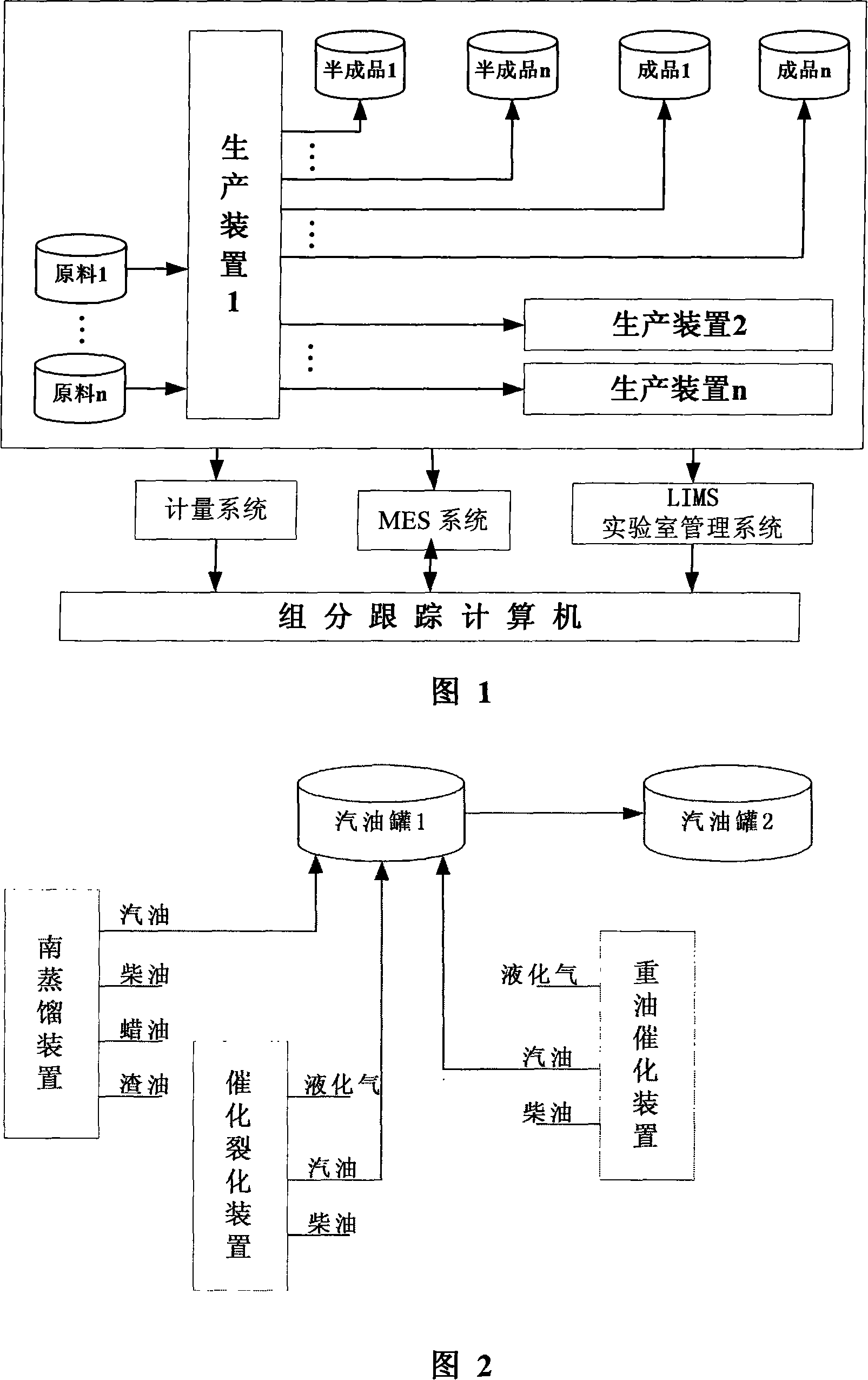

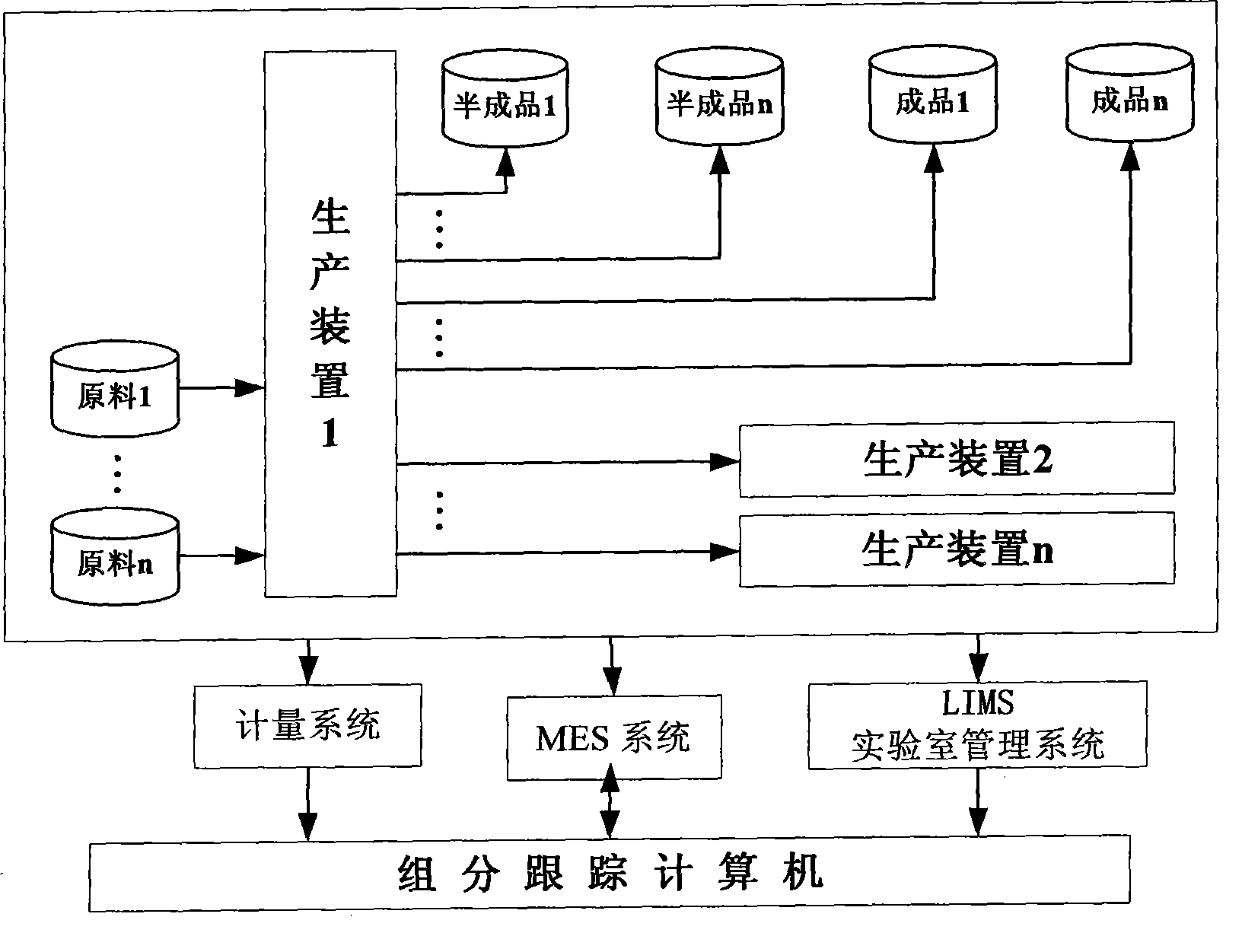

[0034] Refining companies use crude oil and natural gas as their main raw materials to produce fuel, lubricating oil, paraffin and other products to meet the needs of the society while seeking maximum economic benefits for the company. The process of oil refining is continuous production, on a large scale, composed of many complex internally related unit operation modules, see figure 1 , The unit modules are connected to each other by material flow, energy flow and equipment to form different refining and chemical process flows.

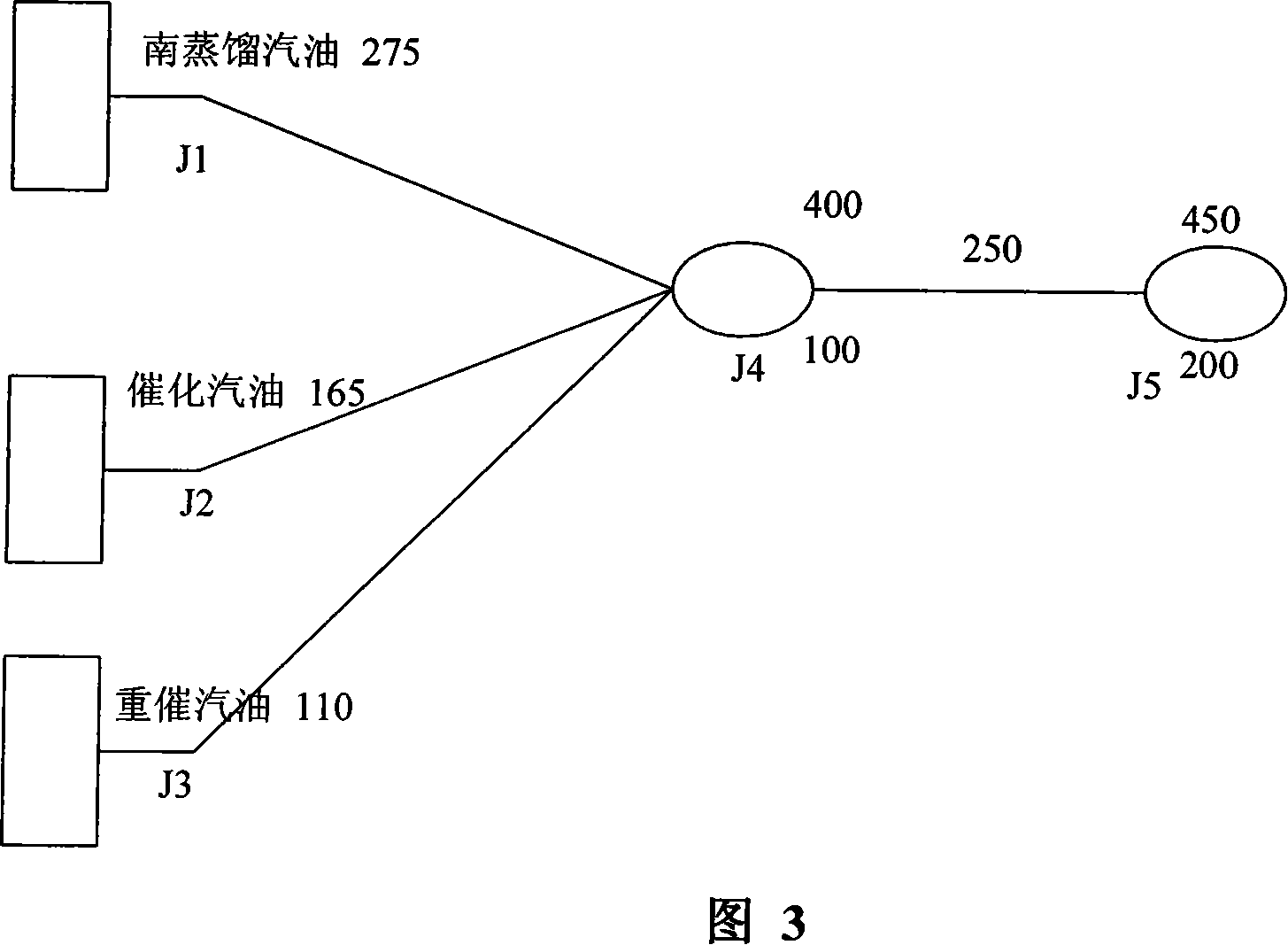

[0035] Device: A combination of equipment used by a refinery to produce gasoline, diesel, kerosene, and wax oil is called a device. The equipment of the oil refinery includes: atmospheric and vacuum, catalytic cracking, heavy oil catalysis, hydrocracking, delayed coking, alkylation, reforming, hydrofining, etc.

[0036] Primary processing and secondary processing: As far as the oil refining process is concerned, it is usually divided into primary processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com