Explosion-proof material and method of processing the same

一种防爆材料、材料体的技术,应用在容器填充方法、容器排放的方法、薄料处理等方向,能够解决受力不规则、储、运不便、受力不均匀等问题,达到防止塌陷变形、储运方便、节省空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

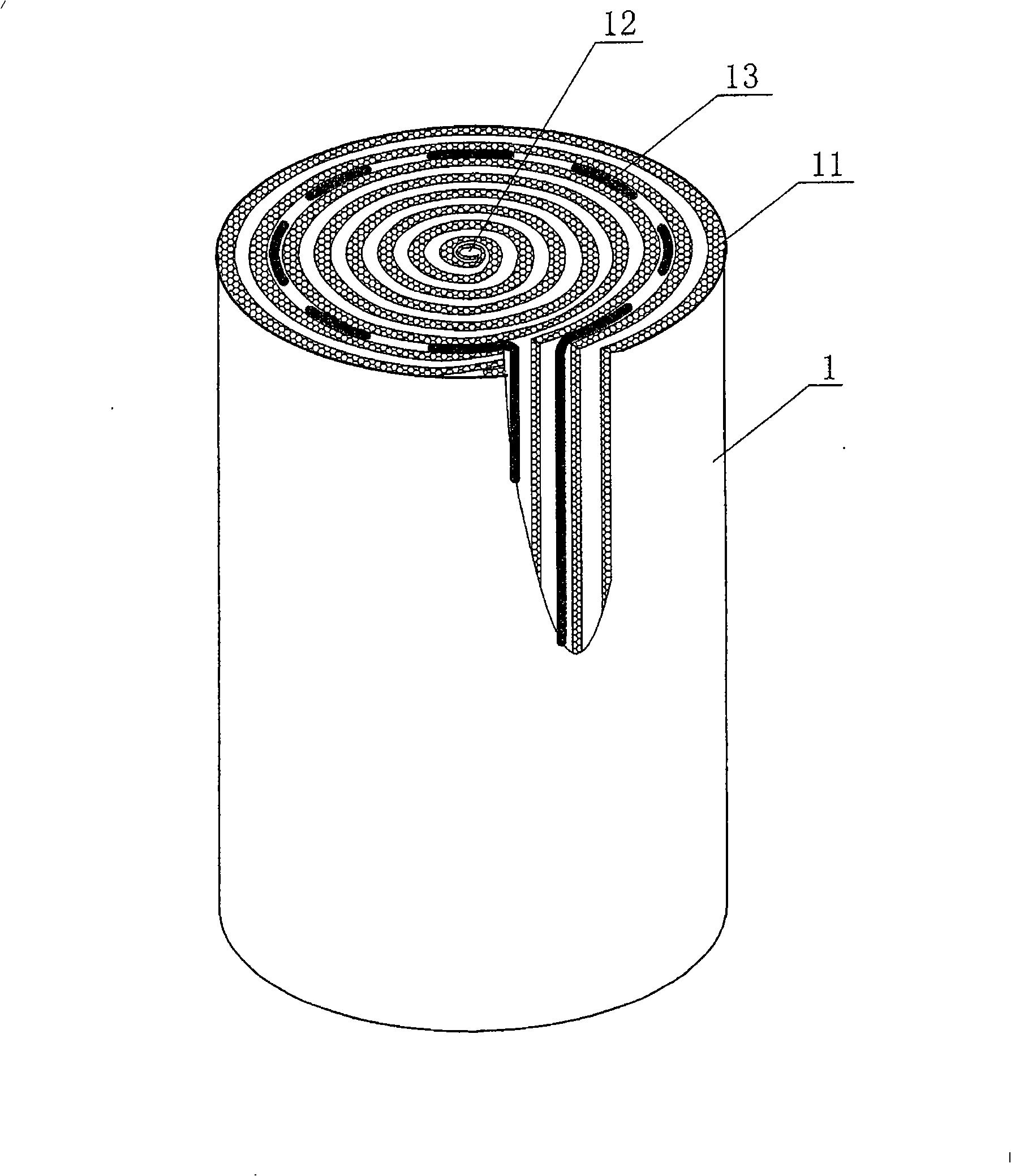

[0080] figure 1 It is a schematic diagram of the overall structure of Embodiment 1 of the present invention. Such as figure 1 As shown, the present invention provides an explosion-proof material, which includes a high-porosity sheet material 11, and is centered on one side 12, and is wound into a multi-layer forming material body 1 along a direction perpendicular to the side 12. A skeleton 13 is inserted into the gap between any two layers of the multi-layer high-porosity sheet material 11 of the material body 1, so that the material body 1 has sufficient strength and elasticity.

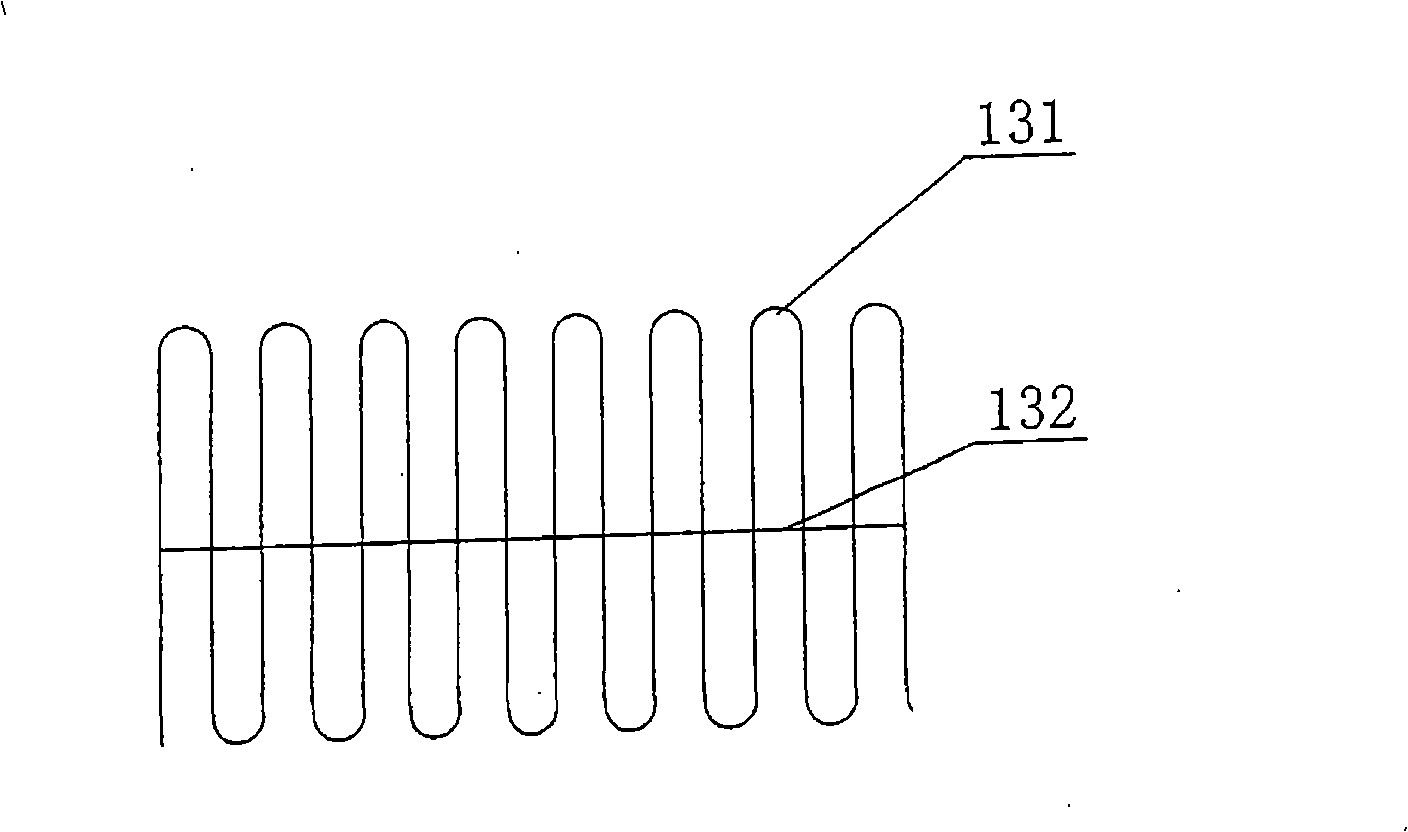

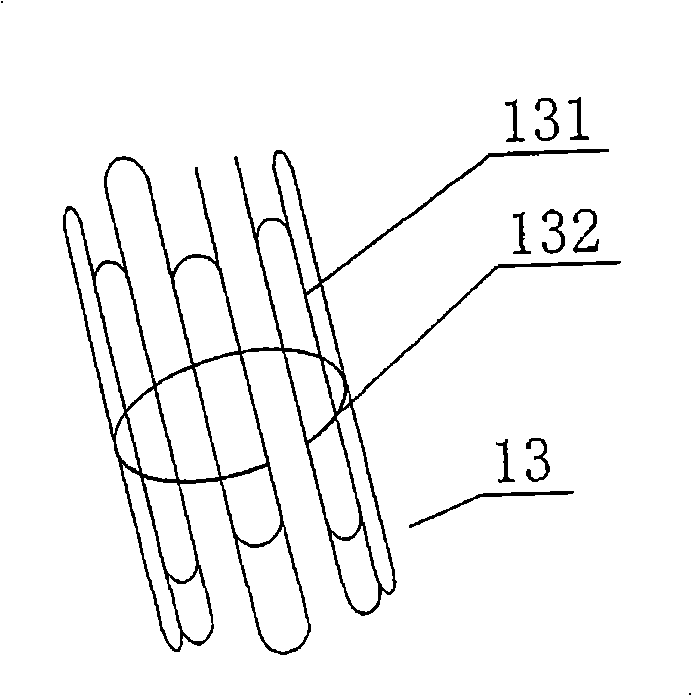

[0081] figure 2 , image 3 They are respectively a schematic diagram of the unfolded structure of the elastic skeleton and a schematic diagram of the overall structure of Embodiment 1 of the present invention. As shown in the figure, in order to effectively support the material body, the skeleton 13 can be an elastic skeleton, which is formed by interweaving a support frame 131 and a reinforcem...

Embodiment 2

[0089] In practical applications, according to different requirements, the support frame can adopt various structural forms, such as Figure 4 , Figure 5 As shown, in this embodiment, the supporting frame 131 is a rectangular frame structure, and the middle part is provided with a reinforcing ring 132 , and the two are interwoven and fixed to form the skeleton 13 . Such as Figure 4 , Figure 5 As shown, in the present embodiment, the skeleton 13 is a rectangular support frame 131 bent by a piece of spring steel through processing, and a reinforcing ring 132 made of elastic material is fixed in the middle to form a rectangular frame piece. Afterwards, Then the rectangular frame sheet is curled into a cylinder to form a rectangular skeleton 13 with elasticity. Other technical features in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0090] It should be noted that, according to the different requirements of the volume and shape of d...

Embodiment 3

[0092] Figure 6 It is a schematic diagram of the overall structure of Embodiment 3 of the present invention, such as Figure 6 As shown, in practical applications, according to different strength requirements, the skeleton 13 can be a continuous skeleton or a discontinuous skeleton; at the same time, in order to achieve better results, in practical applications, the insertion position of the skeleton 13 can be one or many places. In this embodiment, the framework 13 is a continuous framework, which just surrounds the rolled explosion-proof material at a certain interval.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com