A method for winding a stator, as well as a stator and an electric machine with such a stator

A stator and winding technology, applied in the manufacture of motor generators, the shape/style/structure of winding conductors, windings, etc., can solve problems such as winding short circuit and motor locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

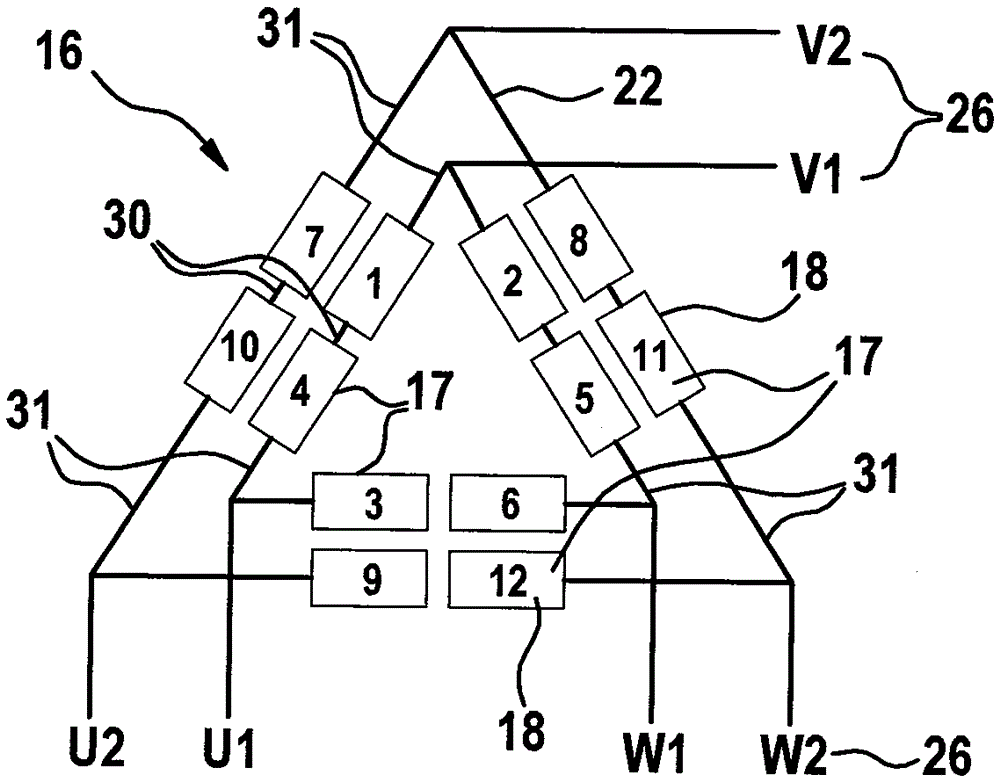

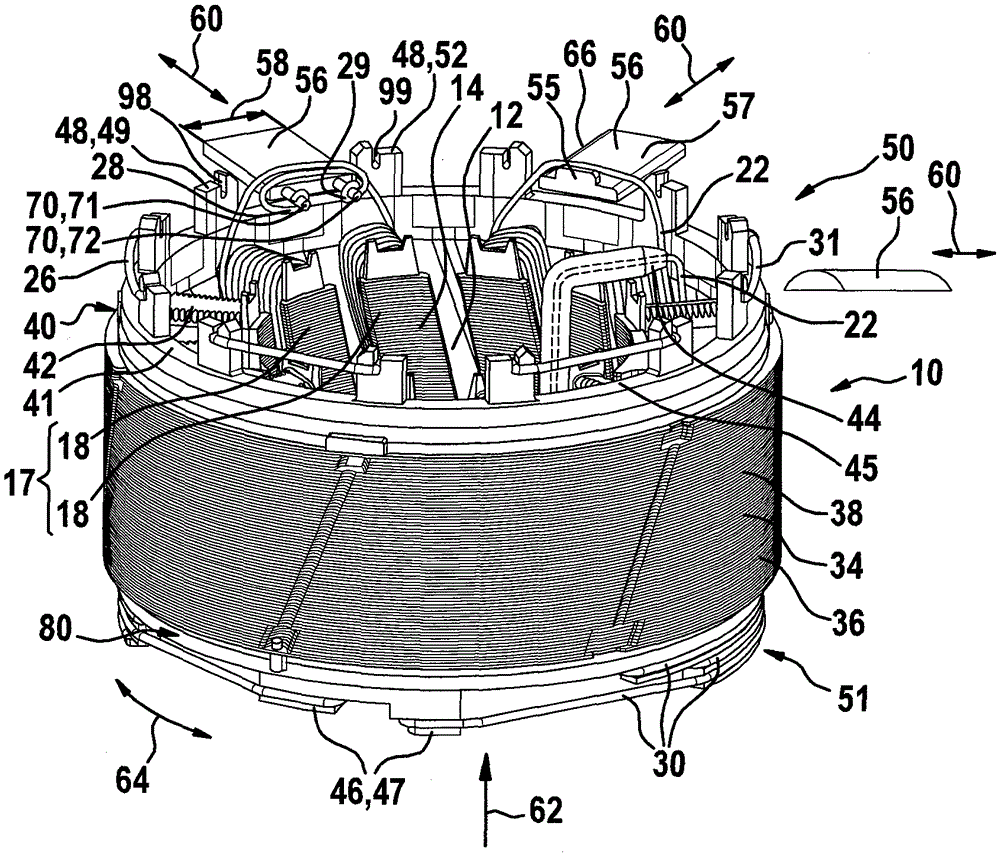

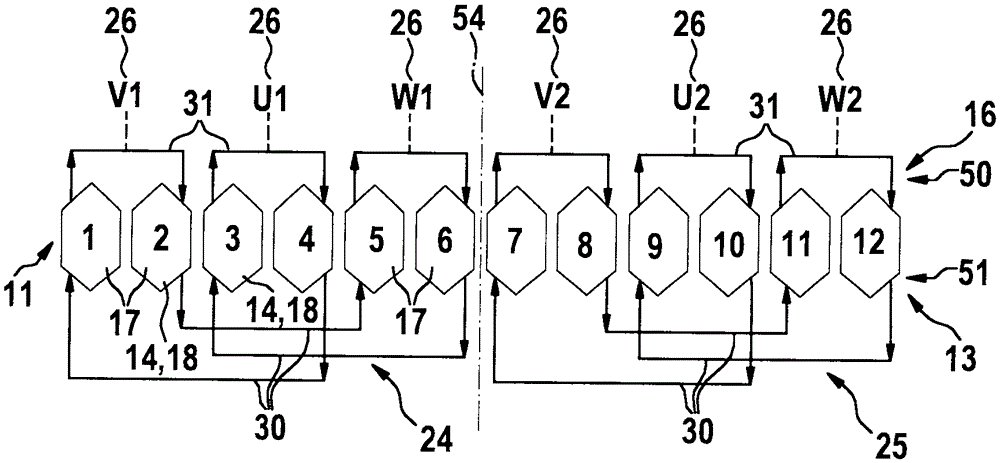

[0022] exist figure 1 The stator 10 is shown schematically in cross section, and the winding diagram of the electrical winding 16 according to the invention is shown on its stator teeth 14 . The stator 10 has, for example, twelve stator teeth 14 , wherein exactly one partial coil 18 is always wound on each stator tooth 14 . In this case, every two sub-coils 18 directly next to each other are connected on the first axial side 50 of the stator 10 by means of short connecting lines 31 to form an adjacent sub-coil pair 17 , which in this exemplary embodiment each form its own phase. 26V1, U1, W1, V2, U2, W2. The three phases 26V1 , U1 , W1 here form their own winding phases 24 , which are wound by separate winding conductors 22 . The three phases 26V2, U2, W2 form a second winding phase 25, which is wound by a second independent winding wire 22 and is electrically insulated from the first winding phase 24, as by figure 1As shown by the dashed-dotted line 54 between the sixth an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com