Circuit board mounting structure and contactor

A technology of installation structure and circuit board, which is applied in the direction of circuits, relays, electromagnetic relays, etc., can solve problems such as product failure, and achieve the effects of good insulation performance, reliable connection, and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

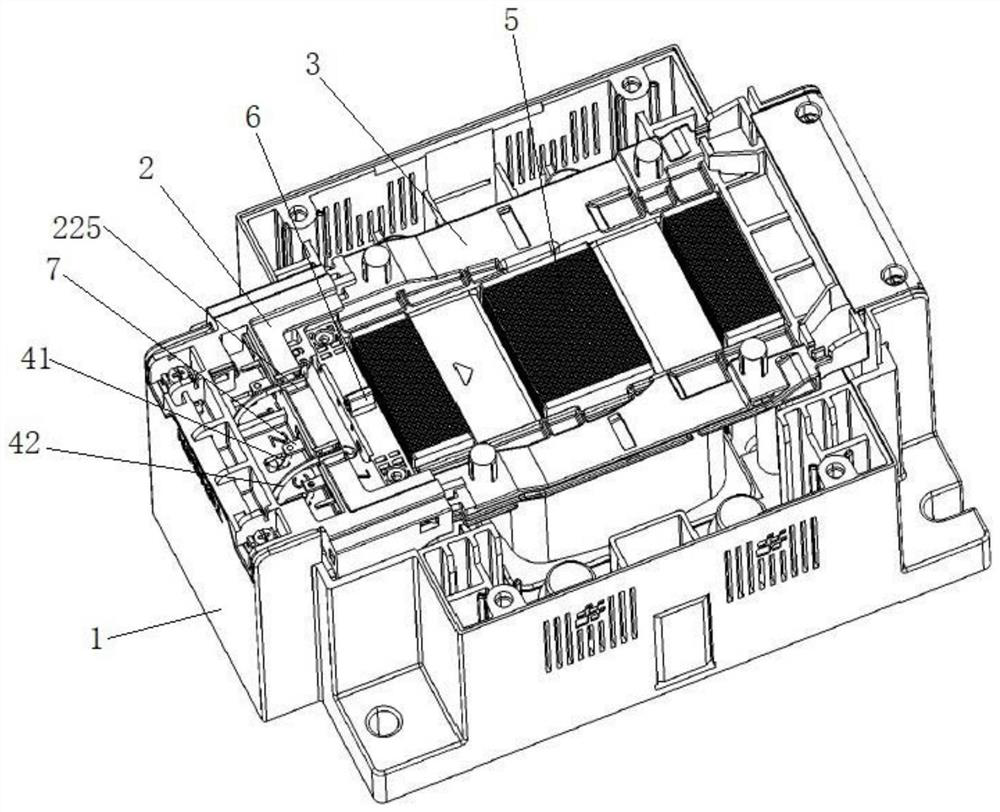

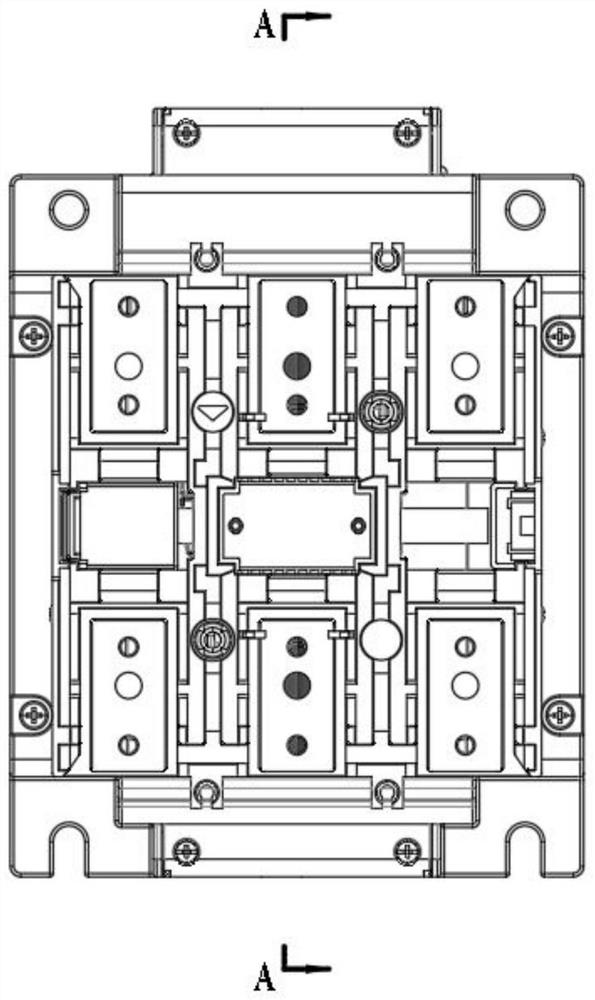

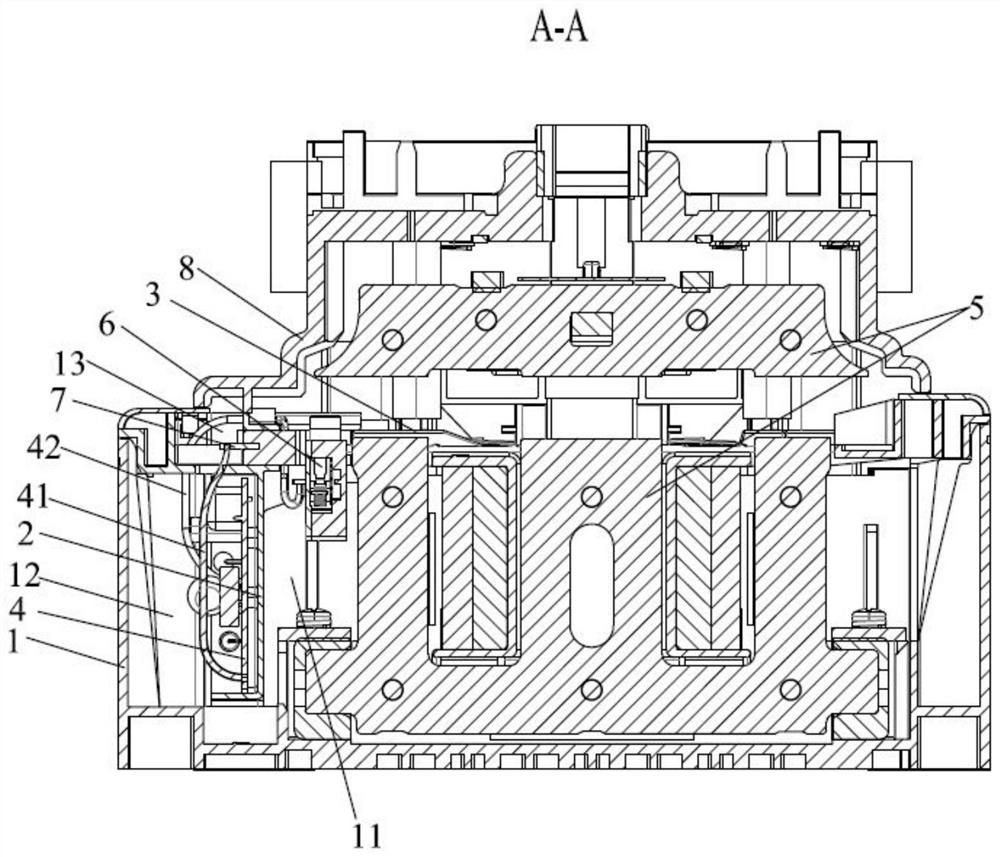

[0070] The circuit board mounting structure of this embodiment, see Figure 1 to Figure 10 As shown, it includes a base 1 , a base 8 , a bobbin 3 , a double coil winding 5 , a case 2 , a circuit board 4 , a switching module 6 , a first wire 41 and a second wire 42 . The bobbin 3 is used to fix the double coil winding 5, on which the lug 7 is fixed. The body shell 2 is suitable for connecting with one end of the coil frame 3 for mounting the circuit board 4 . The switching module 6 is used to control the switching of the double coil winding 5, and is fixed on the bobbin 3, specifically as Figure 4 As shown, the switching module 6 is located between the double coil winding 5 and the body case 2 . Such as Figure 4 As shown, the circuit board 4 is installed on the end of the casing 2 facing away from the double coil winding 5 . Such as image 3 As shown, the first wire 41 is used to connect the circuit board 4 and the lug 7 on the coil frame 3 , and the second wire 42 is us...

Embodiment 2

[0076] The contactor of this embodiment, such as Figure 10 As shown, it includes the circuit board installation structure in Embodiment 1 and the fire extinguishing system 9 arranged above the base 1 and the base 8, and the fire extinguishing system 9 includes an arc extinguishing cover and an arc extinguishing plate assembly. The specific structure of the arc extinguishing plate assembly is not described and limited in detail here, and it is an existing conventional structure. Since the above-mentioned circuit board installation structure is adopted, at least the advantages of the circuit board installation structure of the above-mentioned embodiment 1 are provided, and details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com