Polymer member having incompatible material maldistributed polymer layer and surface uneven tape or sheet made of the polymer member

A polymer layer, uniform distribution technology, applied in the direction of layered products, pressure-sensitive film/sheet, synthetic resin layered products, etc., can solve the problems of adverse effects, time-consuming, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

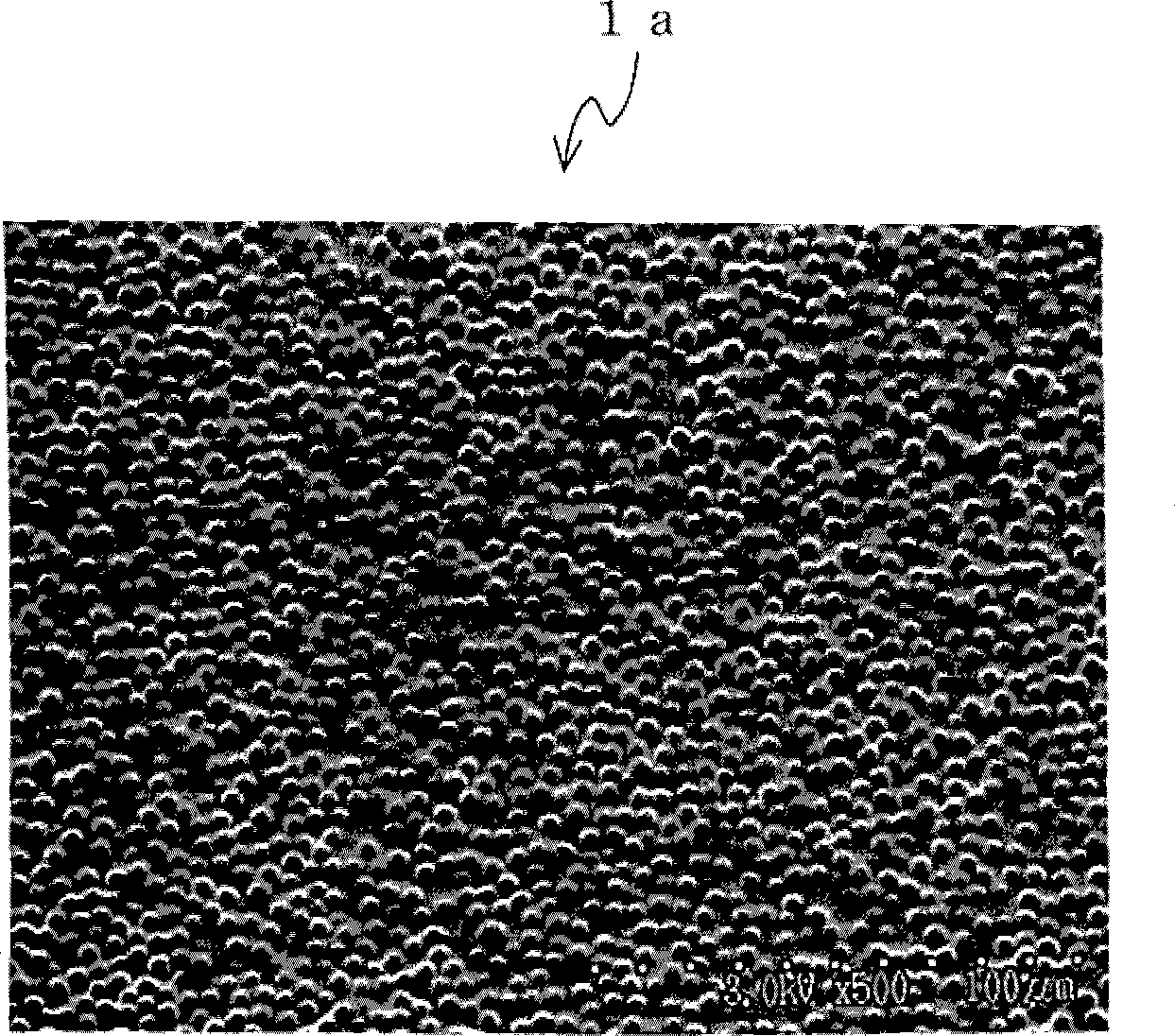

[0383] The particle-combined photopolymerizable composition (A) is coated on the release-treated surface of the above-mentioned cover film so that the thickness after curing becomes 100 μm, and a particle-combined photopolymerizable composition layer is formed, which is combined with a monomer absorbing layer and The form in which the particles are in contact with the photopolymerizable composition layer is bonded to the substrate-attached monomer-absorbing sheet (A) in which the monomer-absorbing layer has been peeled off to form a laminate.

[0384] Next, ultraviolet rays (illuminance: 5 mW / cm 2 ), the particles are combined with the photopolymerizable composition layer to be photocured to form a particle-coordinated photopolymerization cured layer, thereby producing a sheet with uneven surface.

Embodiment 2

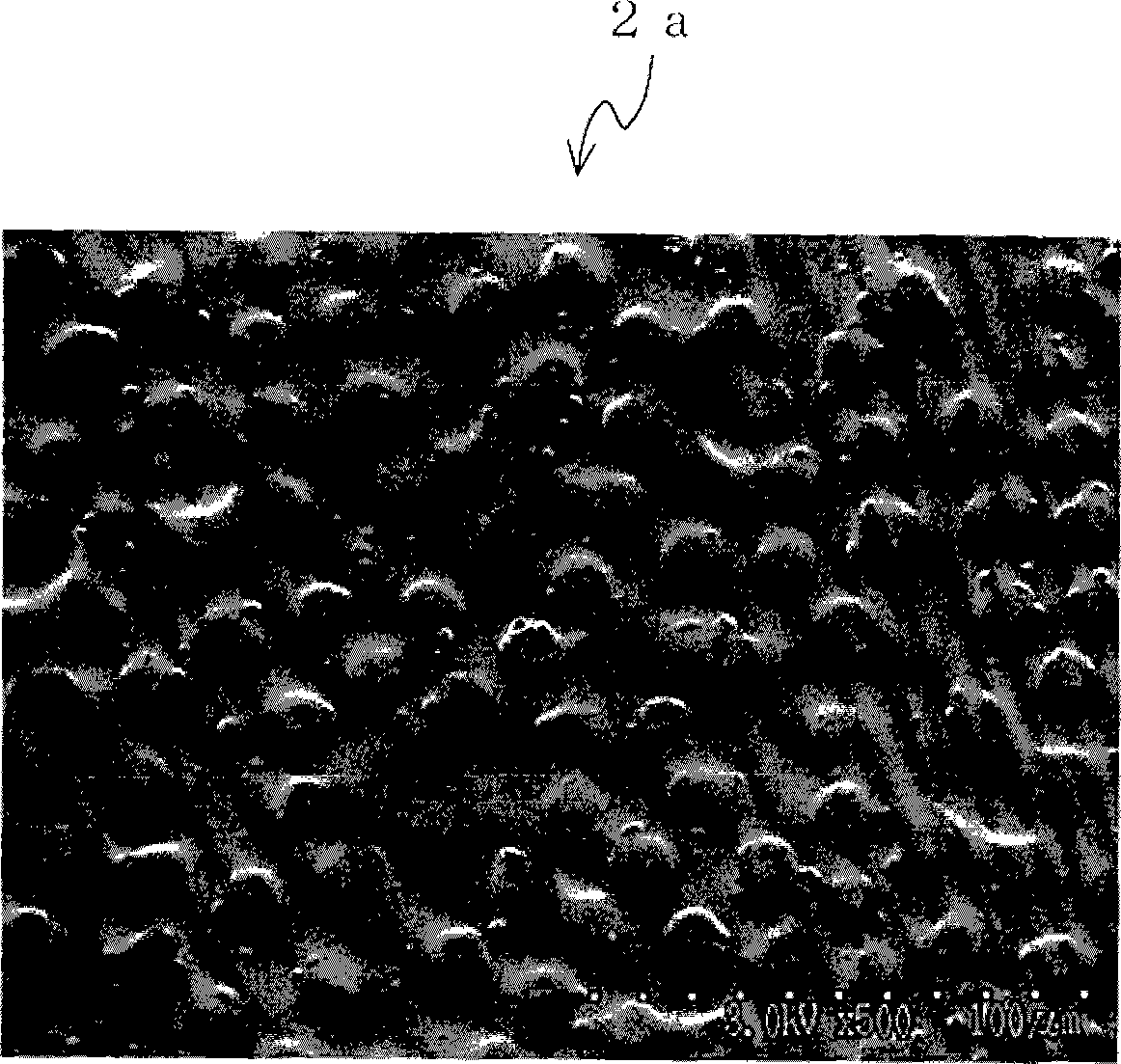

[0386] The particle-combined photopolymerizable composition (B) is coated on the release-treated surface of the above-mentioned cover film so that the thickness after curing becomes 50 μm, and a particle-combined photopolymerizable composition layer is formed, which is separated by a monomer-absorbing layer and The form in which the particles are in contact with the photopolymerizable composition layer is bonded to the substrate-attached monomer-absorbing sheet (A) in which the monomer-absorbing layer has been peeled off to form a laminate.

[0387] Next, 1 minute after forming the laminated body, the laminated body was irradiated with ultraviolet rays (illuminance: 5 mW / cm 2 ), the particles are combined with the photopolymerizable composition layer to be photocured to form a particle-coordinated photopolymerization cured layer, thereby producing a sheet with uneven surface.

Embodiment 3

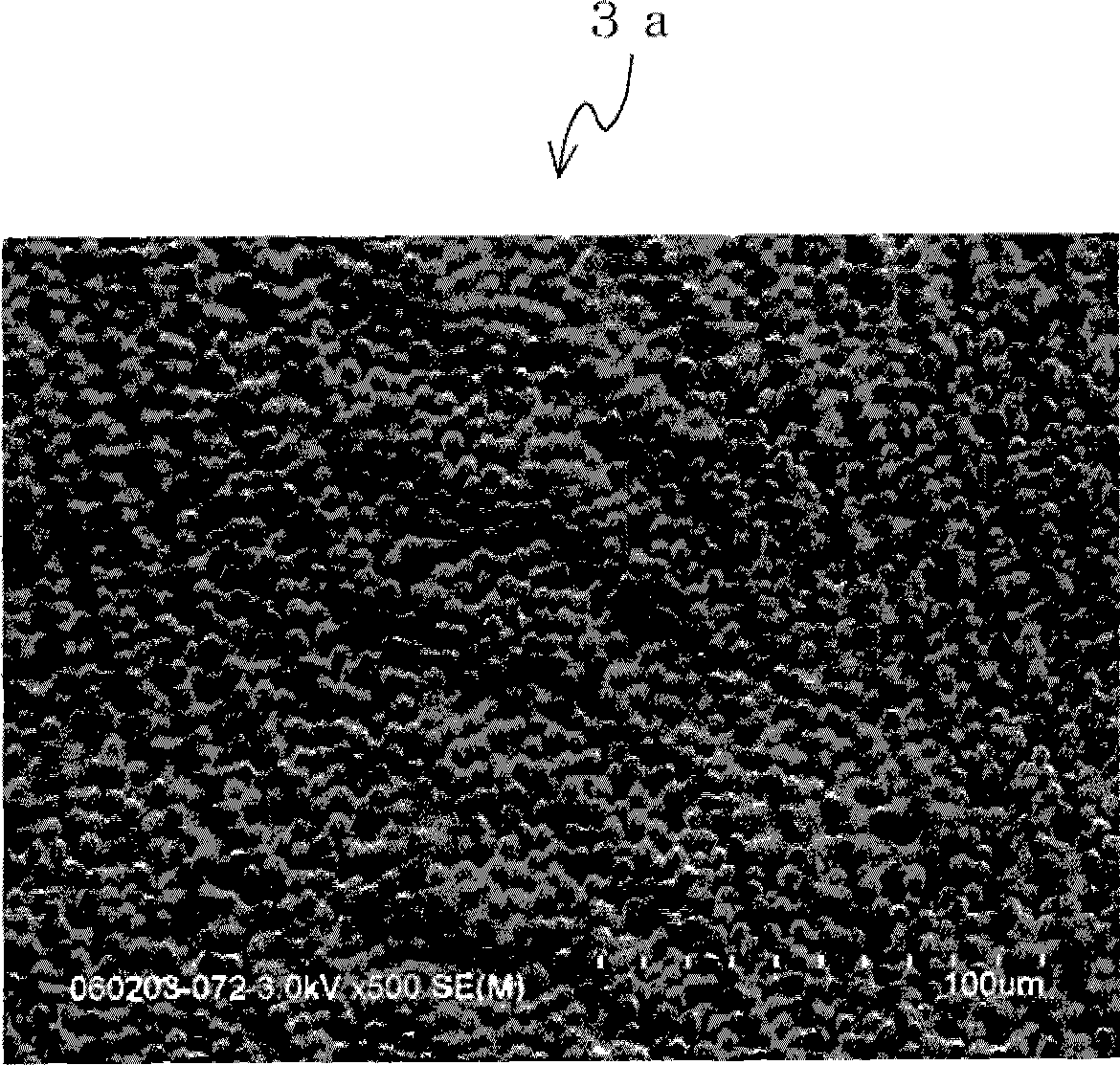

[0389] The particle-combined photopolymerizable composition (A) is coated on the release-treated surface of the above-mentioned cover film so that the thickness after curing becomes 60 μm, and a particle-combined photopolymerizable composition layer is formed, and the monomer-absorbing layer and the The form in which the particles are in contact with the photopolymerizable composition layer is bonded to the substrate-attached monomer-absorbing sheet (B) in which the monomer-absorbing layer has been peeled off to form a laminate.

[0390] Next, 1 minute after forming the laminated body, the laminated body was irradiated with ultraviolet rays (illuminance: 5 mW / cm 2 ), the particles are combined with the photopolymerizable composition layer to be photocured to form a particle-coordinated photopolymerization cured layer, thereby producing a sheet with uneven surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com