Continuous plasma flow ignition exciter

A technology of plasma flow and exciter, which is applied in the direction of electric spark ignition controller, engine ignition, ignition energy generated by generator, etc.

Inactive Publication Date: 2010-12-01

HARBIN ENG UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

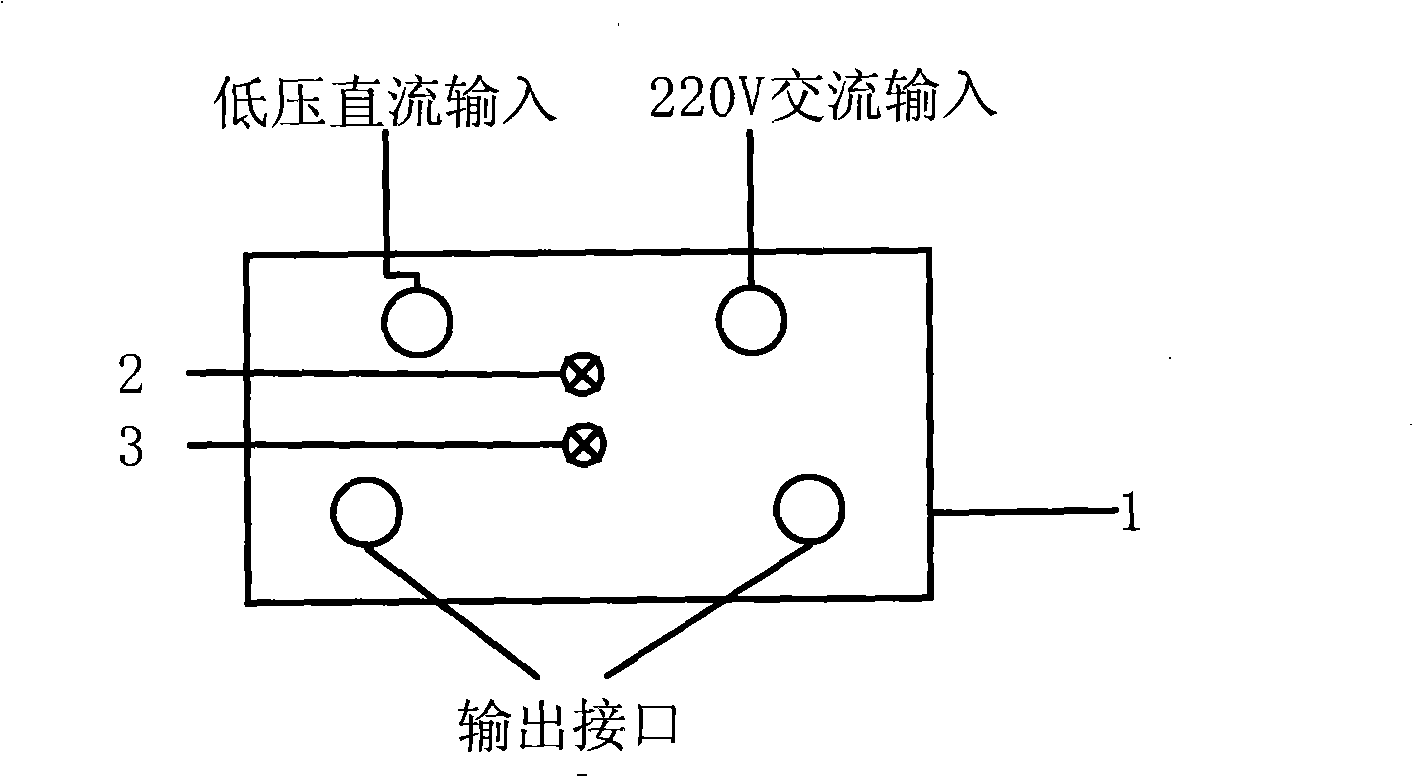

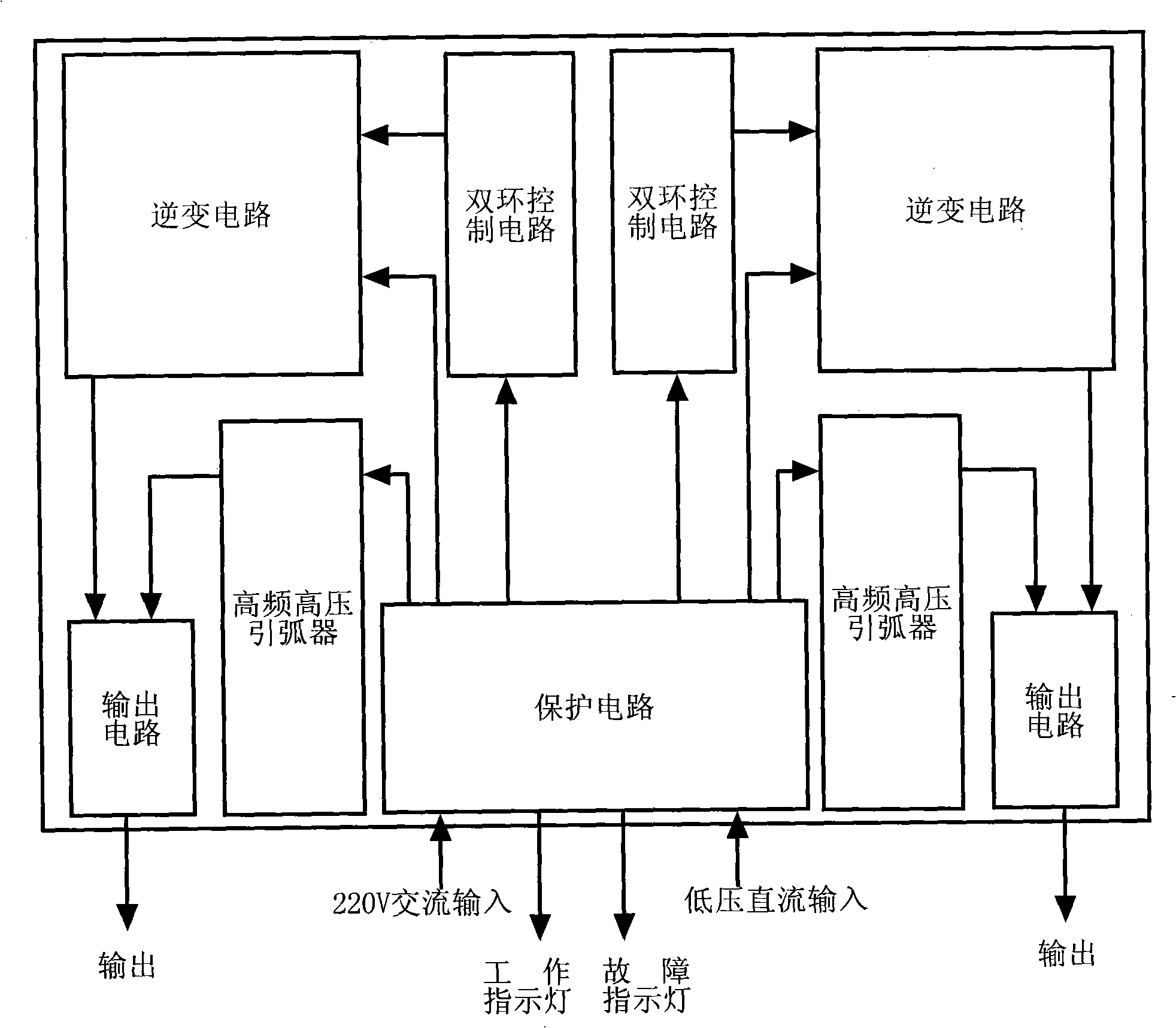

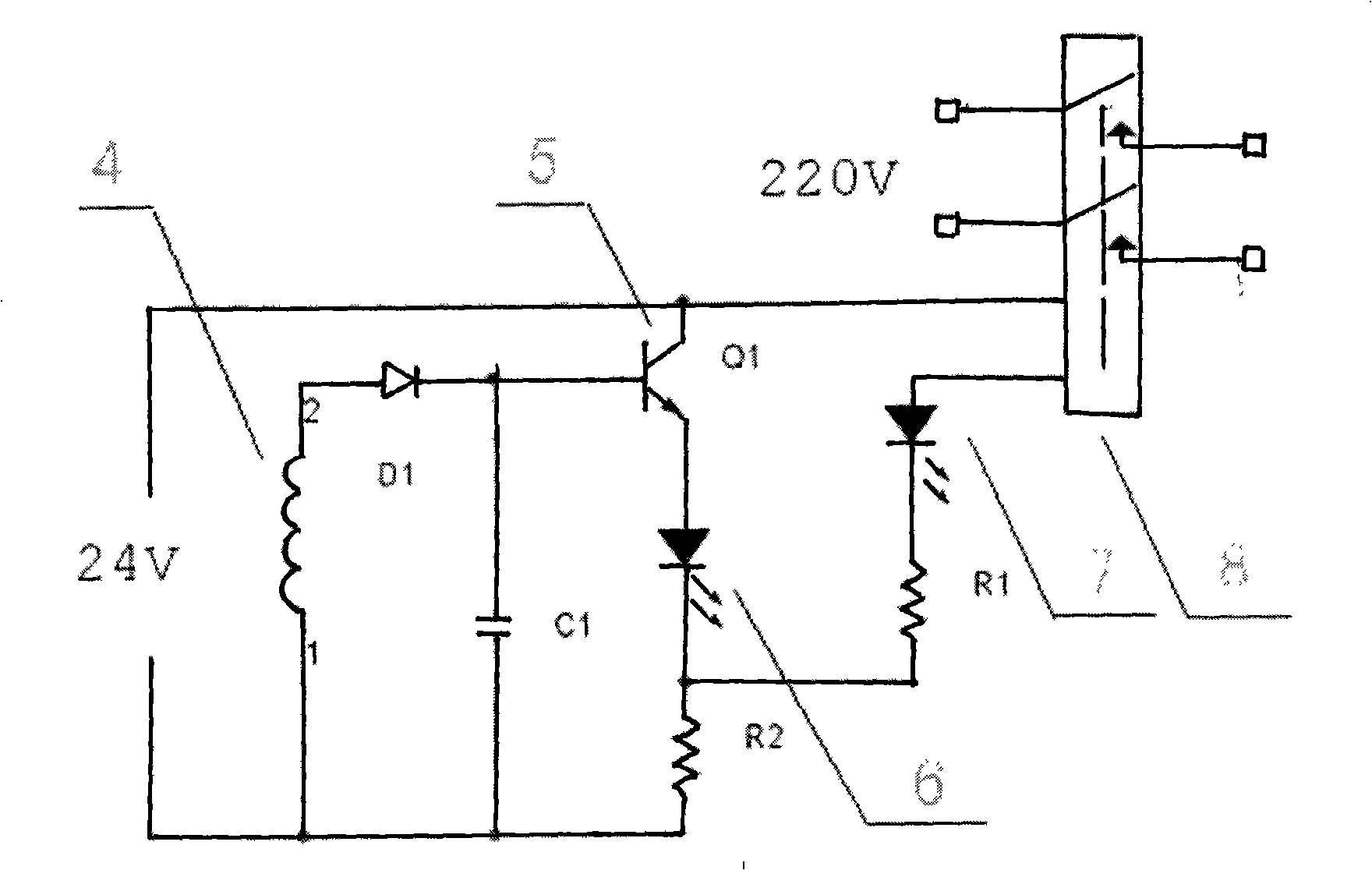

The invention provides a continuous plasma jet ignition exciter unit, comprising a protective circuit, an inverter circuit, a dual loop control circuit, an output circuit and a high frequency high voltage arc generator. The ignition exciter unit is used for providing low current excitation for a plasma jet ignition exciter unit of a gas turbine. The ignition exciter unit adopts a modular design of high frequency switching power supply, thus improving efficiency, and reducing volume and weight; a PWM is adopted to modulate and control impulse width, and the output is stable low current; the dual loop control circuit is adopted to control working mode by means of stabilizing current and restricting voltage, and the output is characterized by steep fall of voltage and constant current of electric current, so that the ignition exciter unit avoids being burned when the output short-cuts.

Description

Continuous Plasma Stream Ignition Actuator (1) Technical field The invention relates to an ignition control device for a heat energy and power device, in particular to a continuous plasma flow ignition exciter suitable for a gas turbine. (2) Background technology Nowadays, gas turbines have been widely used and developed in many fields such as aviation, ships, and power generation due to their advantages such as high power, small weight and size, and high efficiency. During the start-up process of a gas turbine, ignition is critical. The success rate of ignition will be directly related to the safe and reliable operation of the whole device. At present, the commonly used gas turbine ignition methods include electric spark ignition and semiconductor surface discharge ignition. The ignition energy of the electric spark point is low and the ignition delay is long. Although the semiconductor surface discharge ignition can obtain a large ignition power, due to the life of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02P1/00

Inventor 杨家龙郑洪涛谭智勇陈明敏李智明周春良

Owner HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com