Composite material of stannic oxide and carbon, and preparation method thereof

A composite material and tin dioxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problems of complex organic solvent preparation process and unfavorable recovery, etc. Achieve the effects of avoiding adverse effects, low cost, and large application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] According to the preparation method provided by the present invention, the preparation method of the surface oxidized carbon fiber is to contact the carbon fiber with an oxidizing agent. The oxidizing agent can be any substance capable of oxidizing the surface of the carbon fiber to generate electronegative -COOH, -CO and -O functional groups, preferably one of nitric acid and sulfuric acid, more preferably nitric acid. The concentration of described nitric acid and sulfuric acid is not particularly limited, as long as carbon fiber surface can be made to generate electronegative -COOH, -CO and -O functional groups, generally speaking, described nitric acid can be commercially available concentrated nitric acid (concentration is 65% by weight); the sulfuric acid can be commercially available concentrated sulfuric acid (concentration is 98% by weight). Based on 1 gram of carbon fiber, the amount of the oxidizing agent is 50-200 milliliters.

[0018] The time for the carb...

Embodiment 1

[0031] This example is used to illustrate the preparation of nano tin dioxide / carbon composite material of the present invention.

[0032] (1) Surface removal of carbon fiber

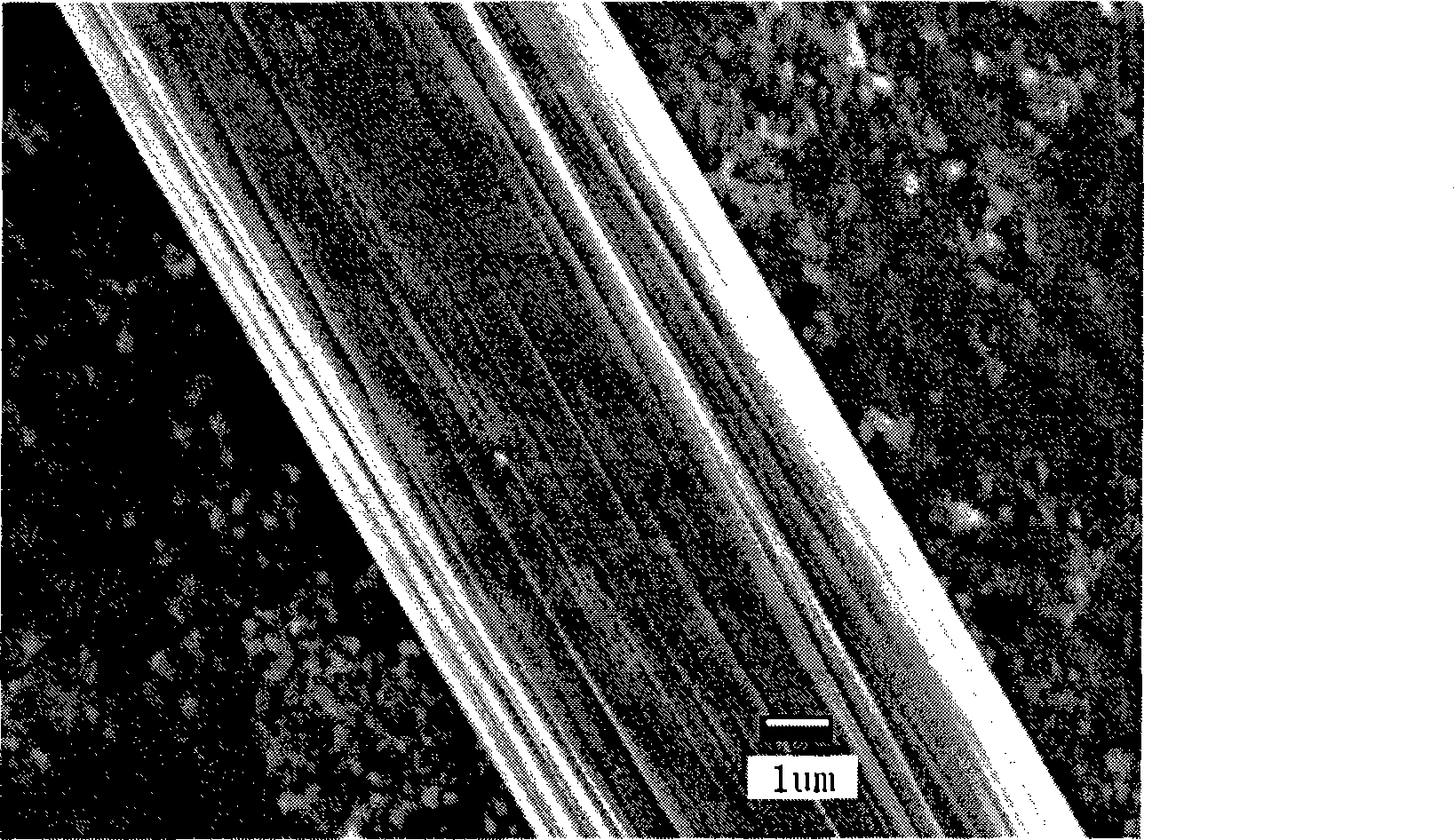

[0033] At room temperature, 0.5 g of carbon fiber ( figure 1 As its SEM image, the average diameter is 8 microns, and the average length is 4 mm) soaked in 50 milliliters of acetone solution for 24 hours. Then, the carbon fibers were washed 5 times with 50 ml of deionized water. The water was removed by suction filtration, and the carbon fibers were dried at 100°C until constant weight.

[0034] (2) Surface oxidation of carbon fiber

[0035] At room temperature, the carbon fibers obtained in step (1) were immersed in 75 ml of concentrated nitric acid solution (65% by weight), ultrasonically oscillated (30 KHz) for 20 minutes, and then soaked at room temperature for 10 hours. Then, the carbon fibers were washed 5 times with 50 ml of deionized water. The water was removed by suction filtration, and t...

Embodiment 2

[0040] This example is used to illustrate the preparation of nano tin dioxide / carbon composite material of the present invention.

[0041] (1) Surface removal of carbon fiber

[0042] With embodiment 1 step (1).

[0043] (2) Surface oxidation of carbon fiber

[0044] With embodiment 1 step (2), difference is that the consumption of concentrated nitric acid is 150 milliliters, and soaking time is changed into 50 hours by 10 hours.

[0045] (3) According to the method described in embodiment 1 step (3), the difference is that the concentration of the sodium hydroxide solution used is 0.5 mol / liter, and the volume is 300 milliliters.

[0046] (4) According to the method described in embodiment 1 step (4), the difference is that the concentration of the tin tetrachloride solution used is 0.12 mol / liter, and the consumption is 30 milliliters, and the rate of addition is 1.5 milliliters / minute.

[0047] (5) With embodiment 1 step (5), product is denoted as A2, and the mean partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com