Composite bone material capable of being injected and preparation method thereof

A technology of bone material and collagen, applied in the field of injectable composite bone material and its preparation, can solve the problem of inability to meet the needs of minimally invasive in situ surgery, and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

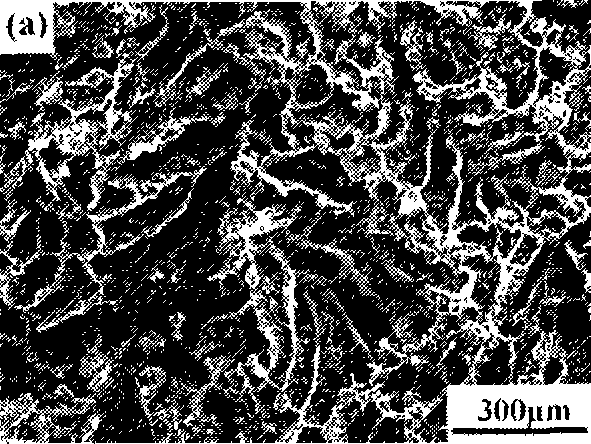

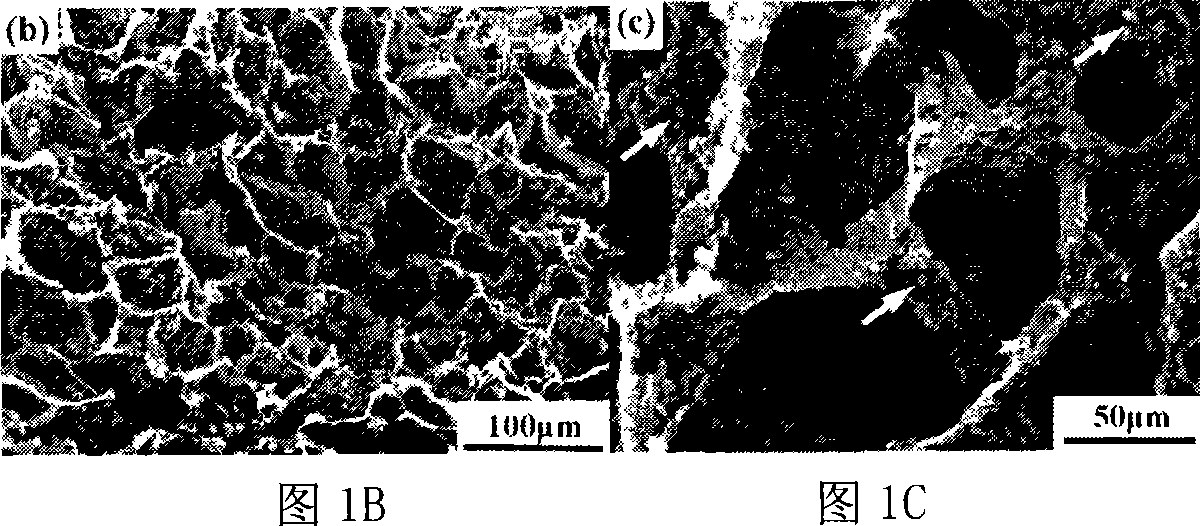

[0028] (1) Dissolve 20g of collagen sol in 300ml of 0.5M acetic acid solution, slowly add 11ml of 1mol / l Na 2 HPO 4 and 18.3ml1mol / lCaCl 2 , while stirring with a magnetic stirrer; then slowly add 0.5ml of 1mol / l NaOH solution dropwise until the pH value is 7; let the solution stand for 1 day, remove the supernatant, centrifuge to separate the precipitate, and wash it repeatedly with deionized water After three times, put it into a freeze drier for drying, and make a dry powder after grinding. (See Figure 1a, Figure 1b, Figure 1c)

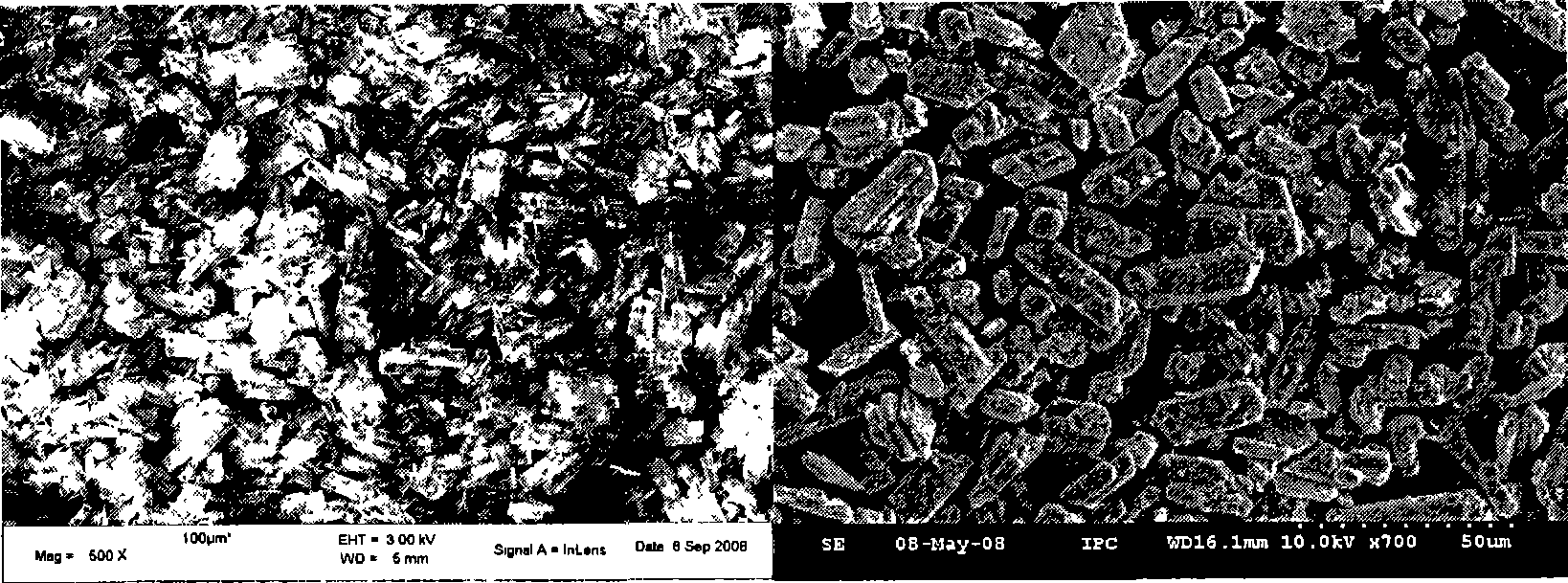

[0029] (2) Take by weighing 100 grams of calcium sulfate dihydrate, 0.25 grams each of sodium citrate and aluminum sulfate, add in the hydrothermal reaction solution, then add 567ml of water, at a reaction temperature of 120 ° C, a pressure of 0.15 MPa, and a stirring speed of 400 rpm React for 6 hours under certain conditions, then filter to obtain precipitate, bake in an oven at 120°C for 2-3 hours, and then put it in an oven at 90°C overnight...

Embodiment 2

[0032] (1) Dissolve 30g of collagen sol in 300ml of 0.5M acetic acid solution, slowly add 11ml of 1mol / l Na 2 HPO 4 and 18.3ml 1mol / lCaCl 2 , while stirring with a magnetic stirrer; then slowly add 0.5ml 1mol / l NaOH solution dropwise until the pH value is 7; let the solution stand for 5 days, remove the supernatant, centrifuge to separate the precipitate, and wash it repeatedly with deionized water After three times, put it into a freeze drier for drying, and make a dry powder after grinding.

[0033] (2) Take by weighing 200 grams of calcium sulfate dihydrate, 0.50 grams each of sodium citrate and aluminum sulfate, add in the hydrothermal reaction kettle, then add 1134ml of water, at a reaction temperature of 110 ° C, a pressure of 0.1 MPa, and a stirring speed of 200 rpm React for 5 hours under certain conditions, then filter to obtain precipitate, bake in an oven at 120°C for 2-3 hours, and then put it in an oven at 90°C overnight, grind to obtain a dry powder, which is c...

Embodiment 3

[0036] (1) Dissolve 8g of collagen sol in 300ml of 0.1M nitric acid solution, slowly add 10ml of 1mol / l (NH 4 ) 2 HPO 4 and 10ml 1mol / lCaCl 2, while stirring with a magnetic stirrer; then slowly add 0.5ml 1mol / l NaOH solution dropwise to pH 7; let the solution stand for 4 days, remove the supernatant, centrifuge to separate the precipitate, and wash it three times with deionized water Afterwards, put it into a freeze dryer for drying, and make a dry powder after grinding.

[0037] (2) Weigh 300 grams of calcium sulfate dihydrate, 0.75 grams each of sodium citrate and aluminum sulfate, add in the hydrothermal reaction kettle, then add 1701ml of water, at a reaction temperature of 130°C, a pressure of 0.2MPa, and a stirring speed of 500 rpm React for 8 hours under certain conditions, then filter to obtain precipitates, bake in an oven at 120°C for 2-3 hours, and then put it in an oven at 90°C overnight, and grind to obtain a dry powder, which is calcium sulfate hemihydrate po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com