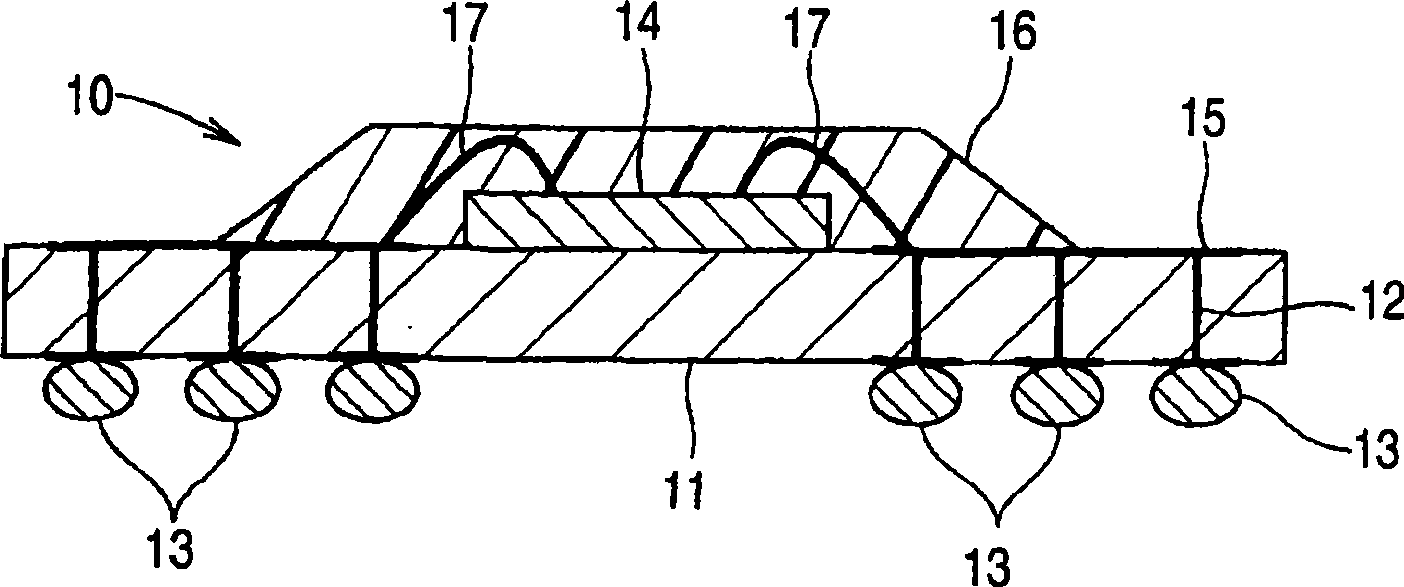

Spherical sintered ferrite particle, semiconductor sealing resin composition making use of the same and semiconductor device obtained therewith

A technology of resin composition and ferrite, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, iron compounds, etc., can solve the problems of insufficient electromagnetic wave shielding and low complex magnetic permeability of resin compositions, and achieve excellent electromagnetic wave The effect of shielding, good EMC characteristics, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0138] Embodiment 1~8, comparative example 1~6

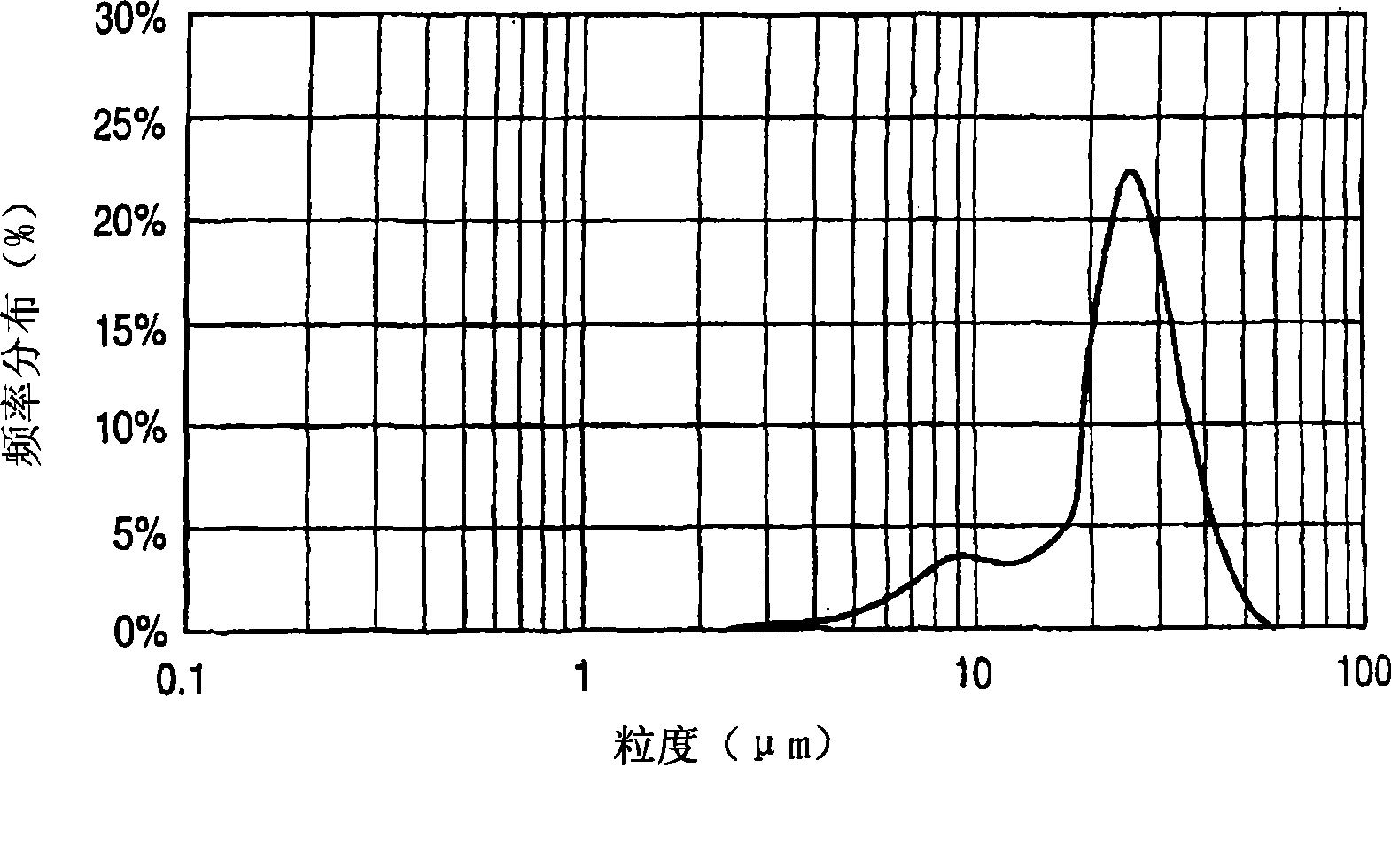

[0139]Use biphenyl type epoxy resin (softening point is 105°C, epoxy equivalent is 192), phenol aralkyl resin (softening point is 60°C, hydroxyl equivalent is 169), bromobisphenol A type epoxy resin (softening point 77 ℃, epoxy equivalent of 465) flame retardant, antimony trioxide, tetraphenylphosphonium tetraphenyl borate, carbon black, silane coupling agent of γ-glycidoxypropyl trimethoxysilane , polyethylene wax, spherical silica powder α (spherical fused silica with an average particle size of 8.0 μm and a maximum particle size of 9.0 μm) and spherical silica powder β (spherical fused silica with an average particle size of 1.5 μm, with a maximum particle size of 1.9 μm), and using the above-mentioned spherical sintered ferrites a to k, these were blended in the ratios in Table 3 and Table 4 below. In Examples 4, 5, 7, and 8, two types of spherical sintered ferrite particles each having a different average particle size wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com