Solar water box with steady flow big heat-exchange surface porcelain enamel heat-exchanging liner

A solar water tank and heat exchange liner technology, applied in the field of solar water tanks, can solve the problems of affecting service life, enamel peeling, small heat exchange surface area, etc., to ensure heat exchange effect, improve pressure bearing capacity, and large heat exchange surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

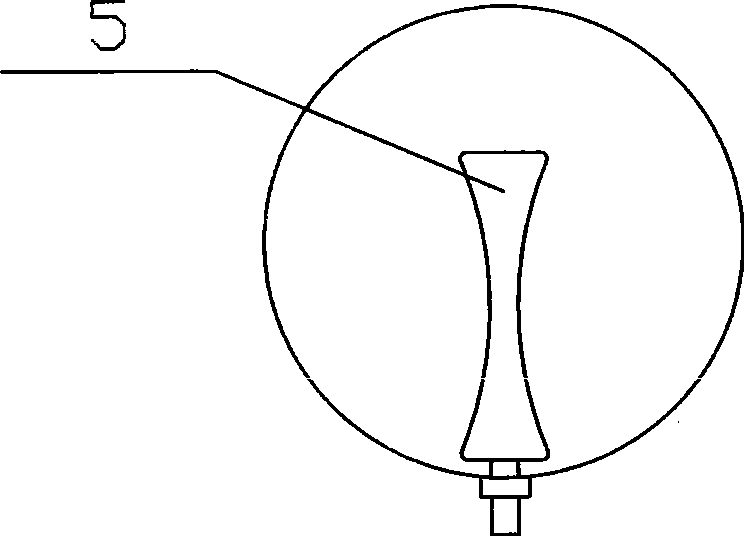

[0010] It can be seen from the accompanying drawings that the solar water tank with a stable flow and large heat exchange surface enamel heat exchange liner includes medium circulation interfaces 1 and 2, a heat exchanger 3 and an inner liner body 4, and the heat exchanger 3 is a long and narrow waist drum Shaped structure, its section 5 is waist drum shape. As another embodiment of the present invention, the heat exchanger 3 may be provided with reinforcing ribs 6, and the reinforcing ribs 6 are distributed vertically and alternately. The reinforcing ribs can be welded inside the heat exchanger with steel plates, and the outer surface of the heat exchanger can be provided with an enamel layer to prolong the service life of the heat exchanger. In use, add circulating medium (oil, water, alcohol, antifreeze, etc.) The heat is transferred to the water in the water tank liner main body 4, thereby achieving the purpose of heating the water. The stiffening ribs distributed up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com