Simple abd rapid water sealing method for larsen steel sheet pile cofferdam

A technology of Larsen steel sheet piles and steel sheet piles, which is applied in construction and infrastructure engineering, etc., can solve the problems of steel sheet pile cofferdam water retaining structures such as failure, poor use effect, and inconvenient operation, and achieve great promotion value and selection The effect of convenient purchase and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

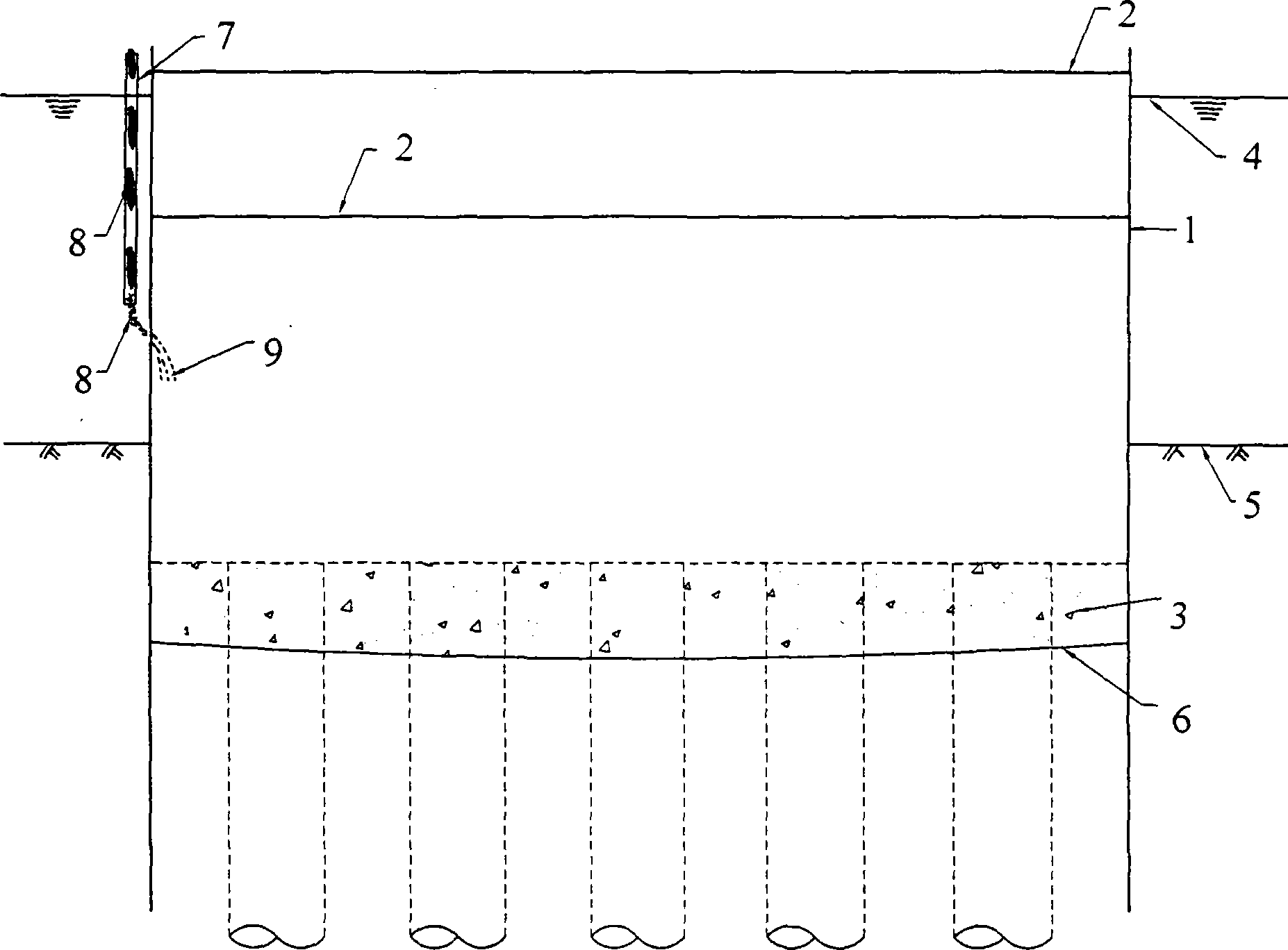

[0009] Control attached figure 1 , after water leakage is found during the pumping process of the steel sheet pile cofferdam, after timely mixing with graded coarse sand, saw foam powder, and cement, a plugging conduit 7 is set at an appropriate position outside the Larsen VI steel sheet pile pile 1 above the water leakage 9, and through the plugging Conduit 7 lowers the plugging compound to the top of the leak plugging, and then under the action of water flow adsorption, coarse sand, saw powder, cement, etc. are sucked into the gaps of the leaking steel sheet piles to fill them tightly to achieve the water-stopping effect.

[0010] The water-stopping method is to first ensure the verticality of the steel sheet pile, and set enough butter in the lock of the steel sheet pile during the insertion process to ensure the quality of the lock; when water leakage is found during the pumping process, use graded coarse sand, saw foam powder, and cement to blend in time (When the water l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com