Method for synthesizing polyatomic alcohol fatty acid ester

A fatty acid ester and polyol technology, which is applied in the field of green synthetic polyol fatty acid ester, can solve the problems of easy decomposition of ionic liquid, large amount of ionic liquid, and limitation of feeding methods, and achieve low cost, easy operation, air and water stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

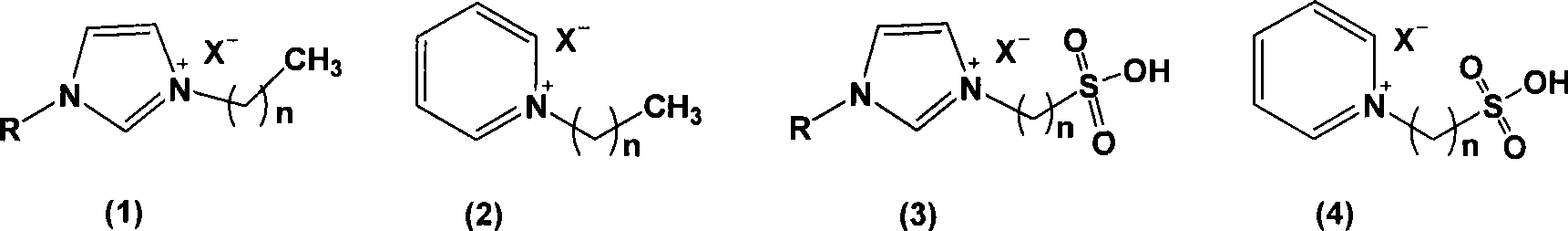

Method used

Image

Examples

Embodiment 1

[0023] In a 250mL three-necked flask, add stearic acid and ethylene glycol at a molar ratio of fatty acid to polyol of 1:1.2, and then add 1-methyl-3-butylimidazole trifluoromethanesulfonic acid with a total mass of 0.2%. salt ionic liquid. Stir and heat up to 175°C. After reacting for 1 hour, the material is discharged. The acid value is 5.8 mgKOH / g, and the esterification rate is 97.3%.

Embodiment 2

[0025] The same method and operation as in Example 1, 0.15% 1,3-dimethylimidazolium methylsulfate was used as the catalyst, the acid value was determined to be 14.1 mgKOH / g after the reaction, and the esterification rate was 92.2%.

Embodiment 3

[0027] In a 250mL three-necked flask, oleic acid and ethylene glycol were added according to the molar ratio of fatty acid to polyol at 1:1.1, and then 1-methyl-3-octylimidazolium bisulfate ionic liquid with a total mass of 0.2% was added. Stir and heat up to 120°C. After reacting for 2 hours, the material was discharged. The acid value was measured to be 8.4 mgKOH / g, and the esterification rate was 94.42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com