Method for producing natural benzaldehyde by employing three-way nozzle atomization

A three-channel, benzaldehyde technology, used in organic chemistry, hydrolysis to prepare carbonyl compounds, etc., can solve the problems of low product quality, high price, and inability to further improve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

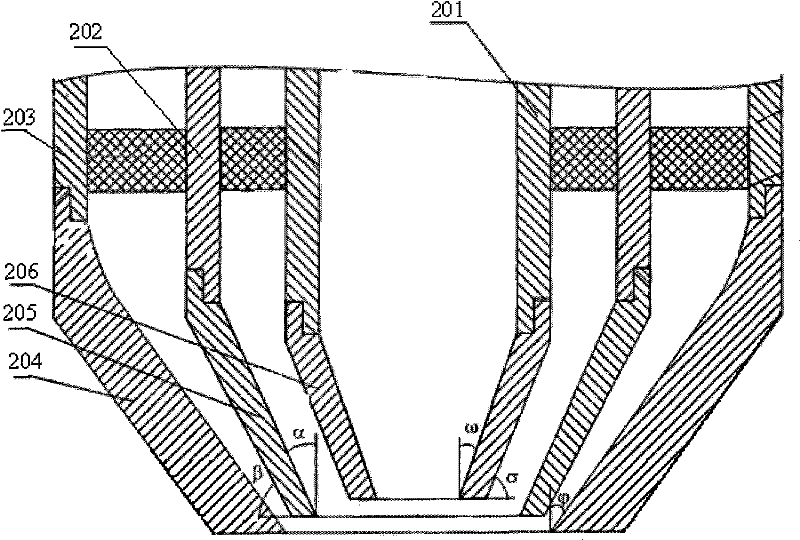

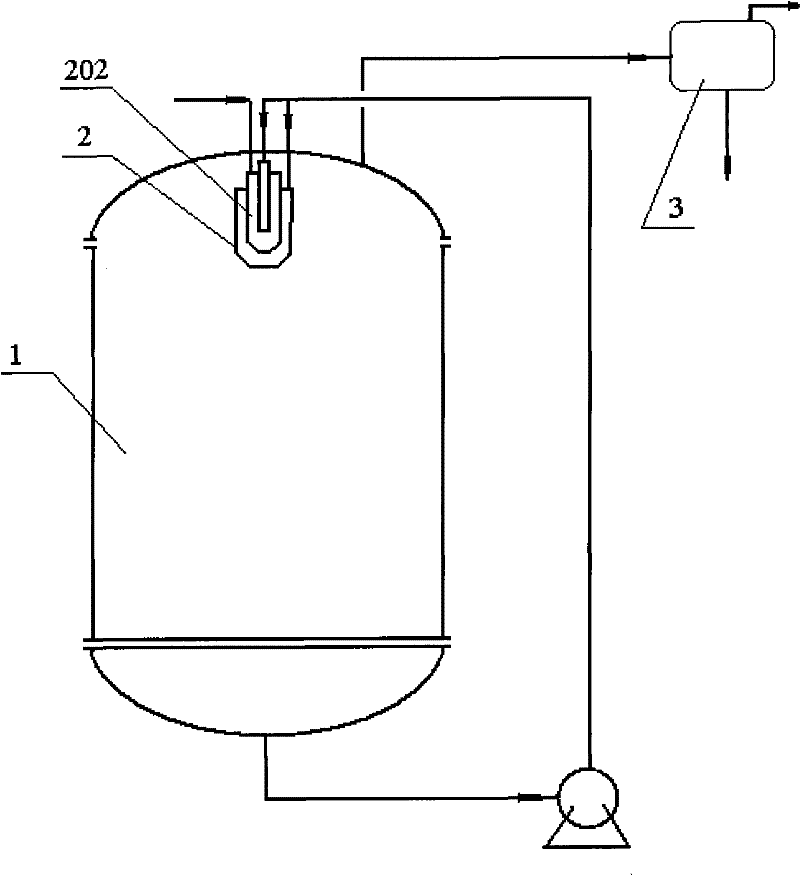

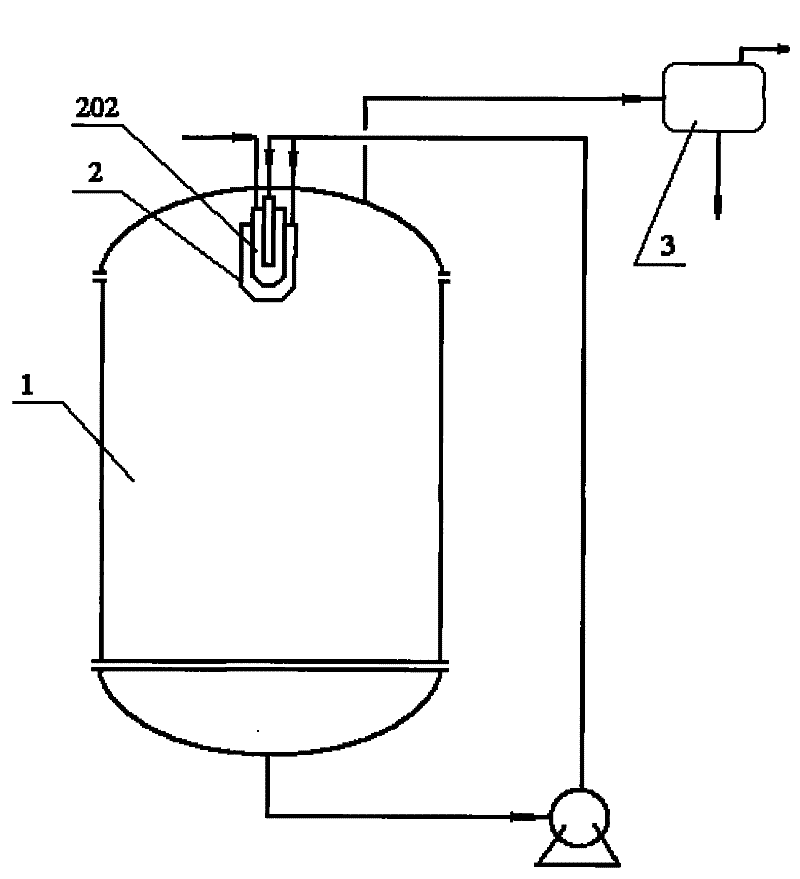

[0025] Using 200 kg of cinnamon oil with 80% cinnamic aldehyde concentration as raw material, using figure 1 The three-channel nozzle and figure 2 Process for the preparation of natural benzaldehyde.

[0026] The structural parameters and operating conditions of the three-channel nozzle are as follows:

[0027] Center nozzle 206: ω is 20°, σ is 65°;

[0028] Inner nozzle 205: α is 30°, β is 65°;

[0029] Outer nozzle 204: is 30°;

[0030] The linear velocity of osmanthus oil at the end outlet of three-passage nozzle 2 is 20 meters per second,

[0031] The linear velocity of the material at the bottom of the reactor 1 at the end outlet of the three-channel nozzle 2 is 300 m / s;

[0032] React at 90°C for 1.5 hours, and the operating pressure during the reaction is 71kPa;

[0033] Alkaline substance is NaOH, and consumption is 0.04% of osmanthus oil weight; The weight concentration of NaOH aqueous solution is 5%;

[0034] After the reaction, 83.9 kg of natural benzaldeh...

Embodiment 2

[0036] Using 200 kg of cinnamon oil with 80% cinnamic aldehyde concentration as raw material, using figure 1 The three-channel nozzle and figure 2 Process for the preparation of natural benzaldehyde.

[0037] The structural parameters and operating conditions of the three-channel nozzle are as follows:

[0038] Center nozzle 206: ω is 10°, σ is 50°;

[0039] Inner nozzle 205: α is 10°, β is 50°;

[0040] Outer nozzle 204: is 10°;

[0041] The linear velocity of osmanthus oil at the end outlet of three-passage nozzle 2 is 10 m / s,

[0042] The linear velocity of the material at the bottom of the reactor 1 at the end outlet of the three-channel nozzle 2 is 50 m / s;

[0043] React at 80°C for 1.5 hours, and the pressure during the reaction is 47kPa;

[0044] Alkaline substance is Na 2 CO 3 , the consumption is 0.01% of osmanthus oil weight; The weight concentration of NaOH aqueous solution is 1%;

[0045] After the reaction, 84.8 kg of natural benzaldehyde with a weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com