Loop type heat pipe radiator and manufacturing method thereof

A technology of a heat dissipation device and a manufacturing method, which is applied to circuits, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of shortened battery life, fan interference, system damage, etc., and achieves reduced contact thermal resistance and high heat dissipation power. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

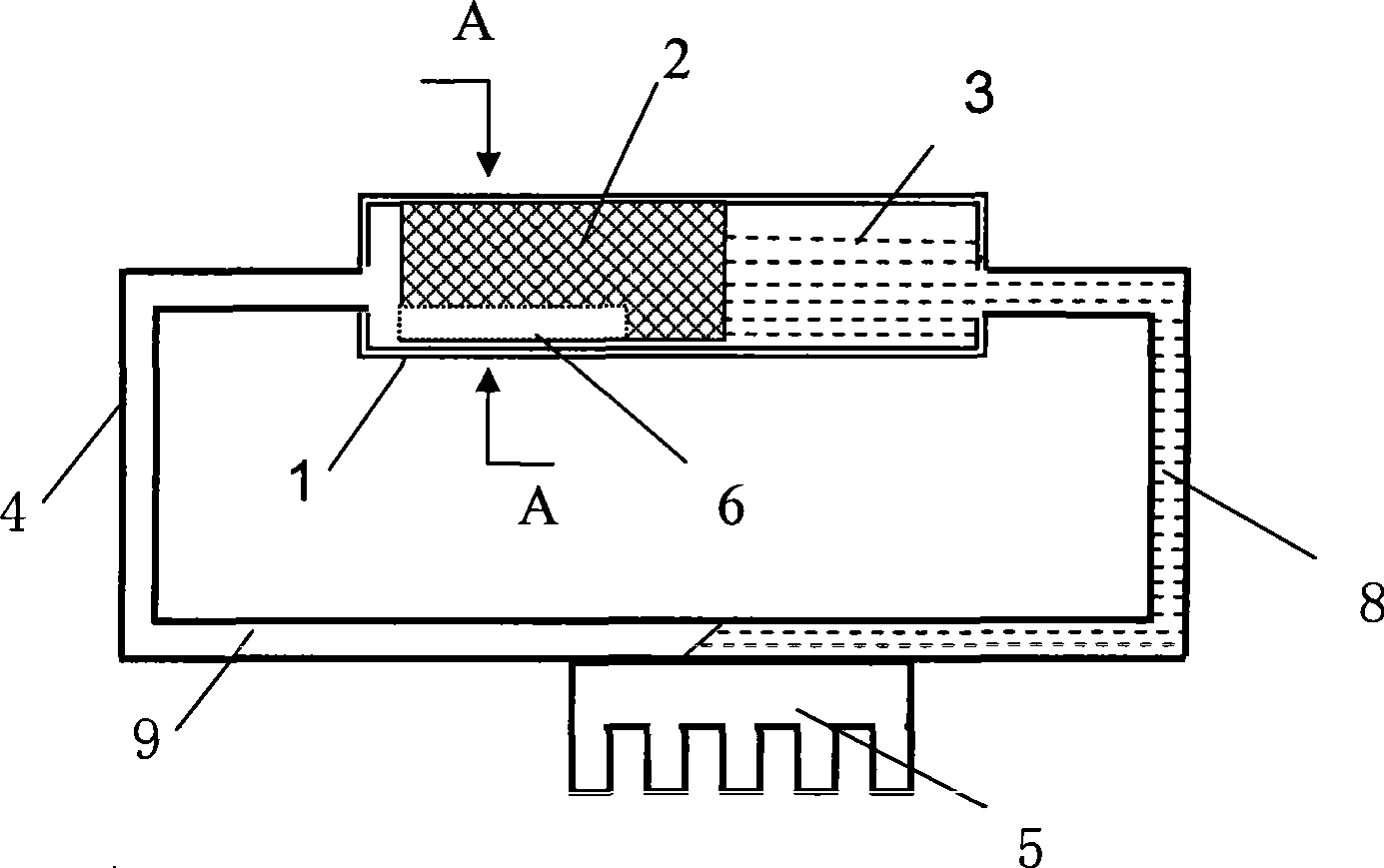

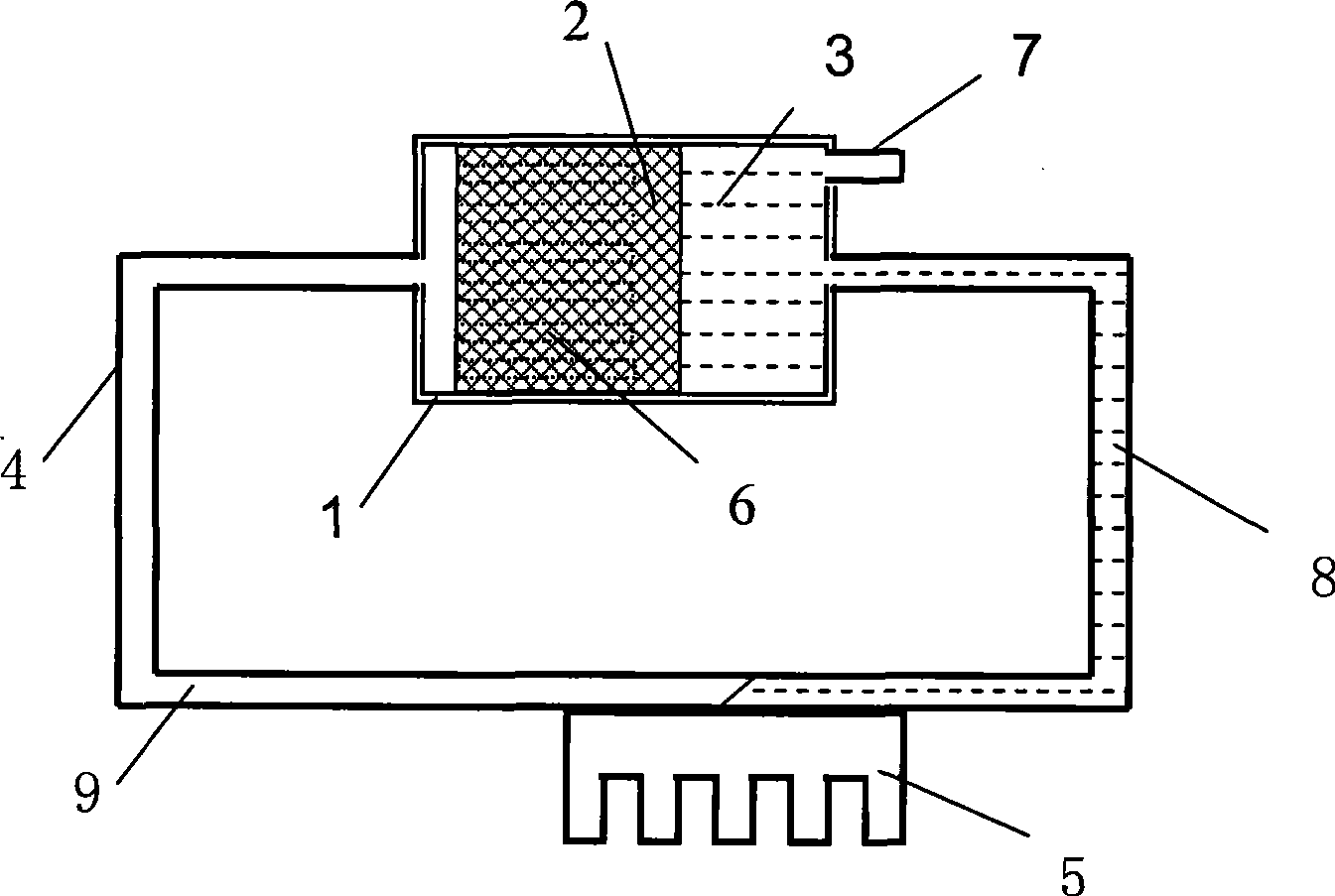

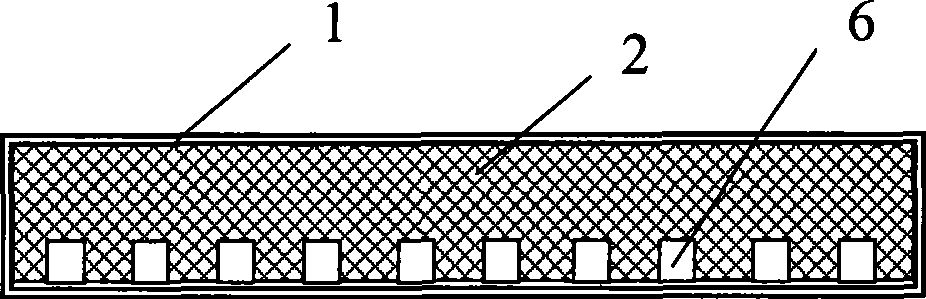

[0038] Such as figure 1 , figure 2 The loop heat pipe cooling device shown includes a flat plate evaporation chamber 1, a porous capillary structure 2 and an external pipeline, the porous capillary structure 2 is filled in the flat plate evaporation chamber 1, and the external pipeline 4 is connected to The two ports of the flat plate evaporation chamber 1, the external pipeline 4 forms a closed loop with the flat plate evaporation chamber 1, the external pipeline 4 is divided into a steam area 9 and a fluid area 8, and the steam area 9 It is connected with a port of a flat-plate evaporation chamber 1 provided with a porous capillary structure 2 . The flat plate evaporation chamber 1 is filled with a certain amount of working fluid 3, and the working fluid 3 is filled in the space o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com