Fiber reinforcement composite material rope bridge and preparation method thereof

A composite material and fiber reinforced technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of low span of cable bridges and poor safety performance of connection points, and achieve light weight, convenient molding and high tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

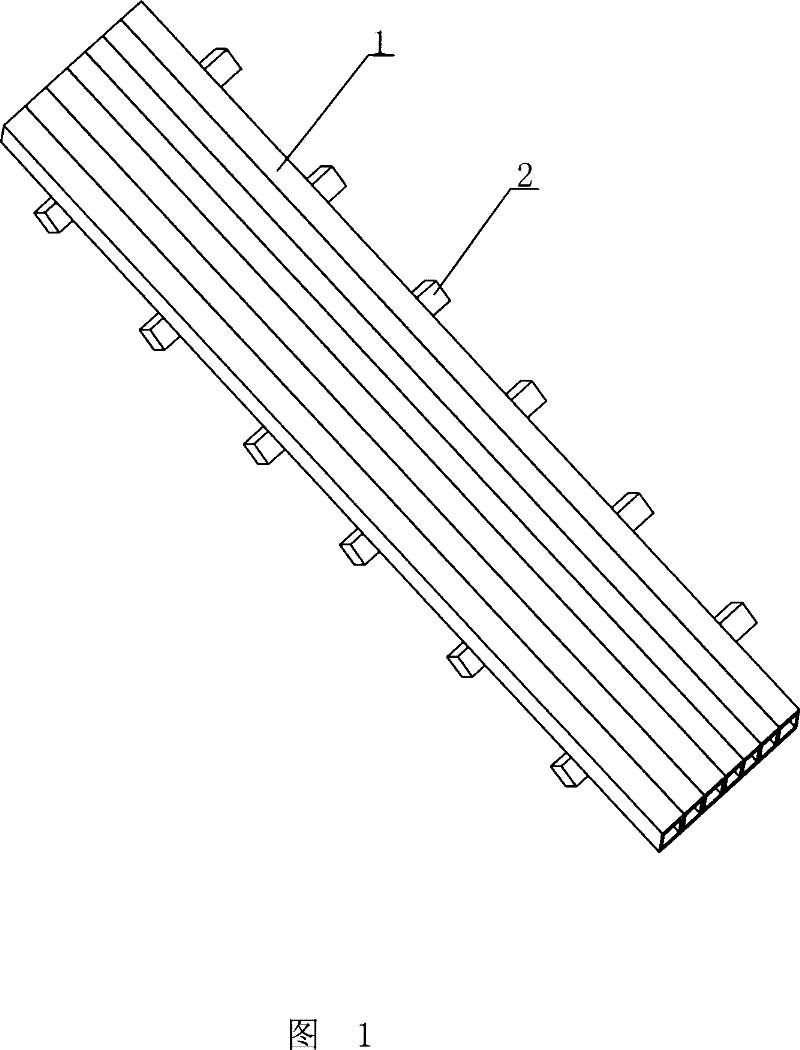

[0025] Example 1 as figure 1 As shown, the bridge deck body of the fiber reinforced composite material cable bridge is composed of a plurality of fiber reinforced composite material bridge components 1 extending along the length direction of the cable bridge arranged side by side. The length of the fiber-reinforced composite material bridge member is equal to the length of the bridge deck. The fiber-reinforced composite material strong beam member is a hollow tubular structure with a rectangular cross-section. The fiber-reinforced composite material bridge member is a pultruded profile, and the length of the pultruded profile can be 1000m. ,

[0026] The preparation method is to use on-site pultrusion molding machinery to prepare a number of FRP fiber reinforced composite bridge components equal to the length of the bridge deck, and arrange multiple fiber reinforced composite bridge components side by side to form the main body of the bridge deck; A support beam is arranged ...

Embodiment 2

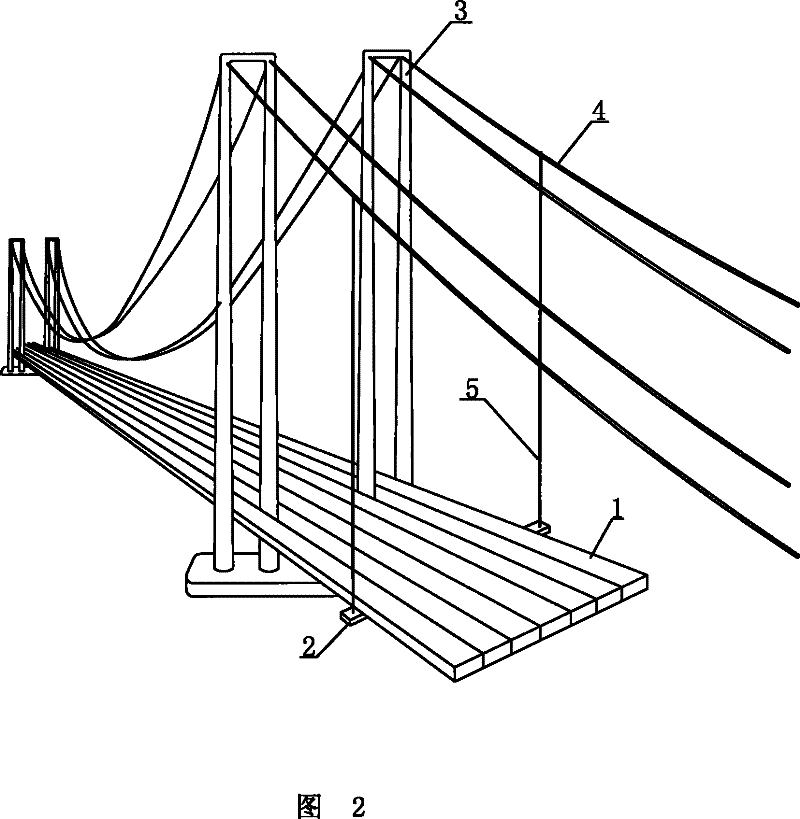

[0027] Example 2 as figure 2 The fiber-reinforced composite material cable bridge is a double-tower cable-stayed cable bridge. The main body of the bridge deck is composed of a plurality of fiber-reinforced composite material bridge components 1 extending along the length direction of the cable bridge. The supporting beam 2, the two ends of the supporting beam are connected and fixed by the sling 5 connected with the stay cable 4, the stay cable is erected on the pylon 3, and the overall bridge weight is supported by two sets of pylons, the fiber reinforced composite bridge member The length is equal to the length of the bridge deck. The fiber-reinforced composite material strong beam member is a honeycomb structure with a rectangular cross-section. The fiber-reinforced composite material bridge member is a pultruded profile, and the length of the pultruded profile can be 3000m. ,

[0028] The preparation method is to use on-site pultrusion molding machinery to prepare a num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com