Stacked multi-layer rubber bag sealing structure capable of meeting large gap requirement and use method thereof

A closed structure and rubber bladder technology, which is applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve the problems of inability to monitor the mold bag pressure in real time, no backup measures, rubber bladder damage, etc., to reduce the risk of machine jamming, Prevent TBM equipment from locking up and install efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be understood that the embodiments described below are only a part of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained without making creative efforts belong to the protection scope of the present invention.

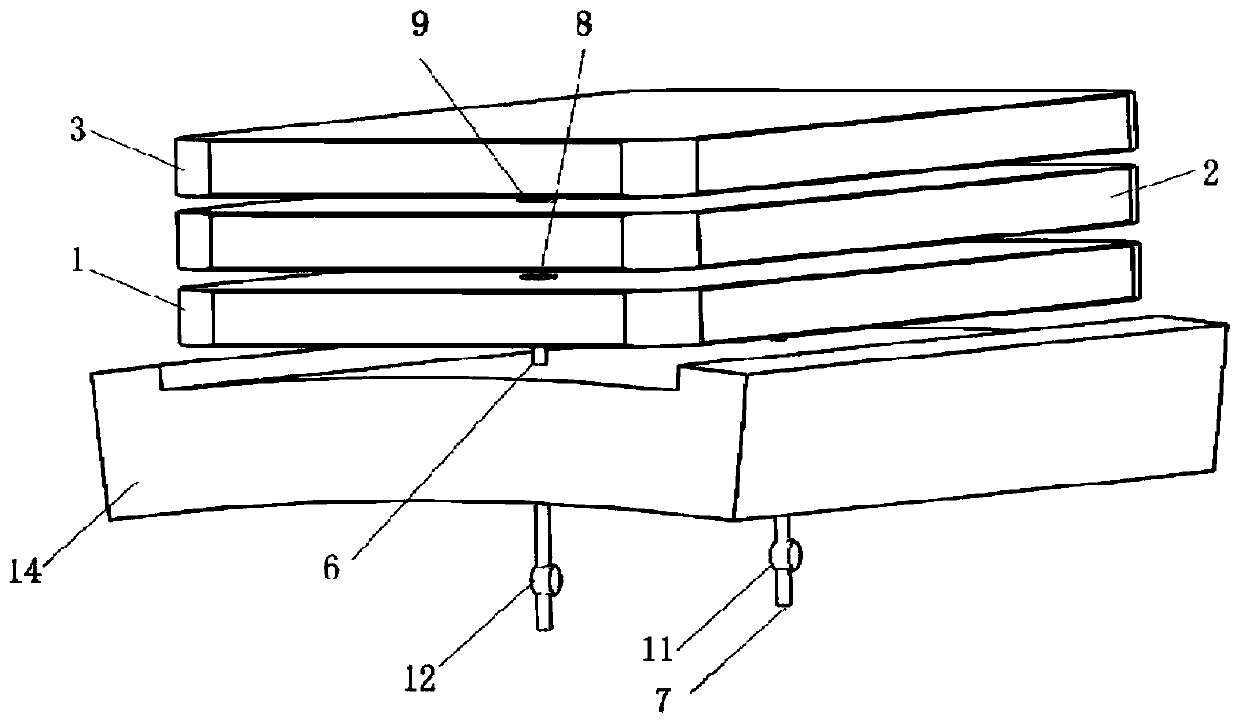

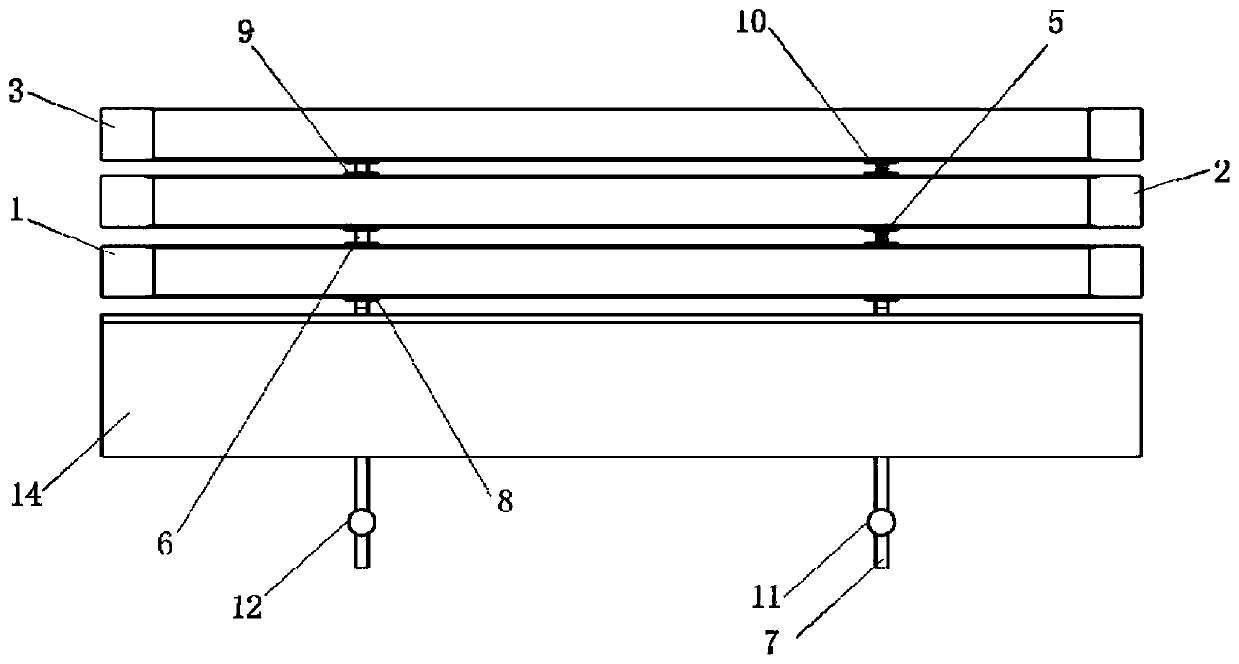

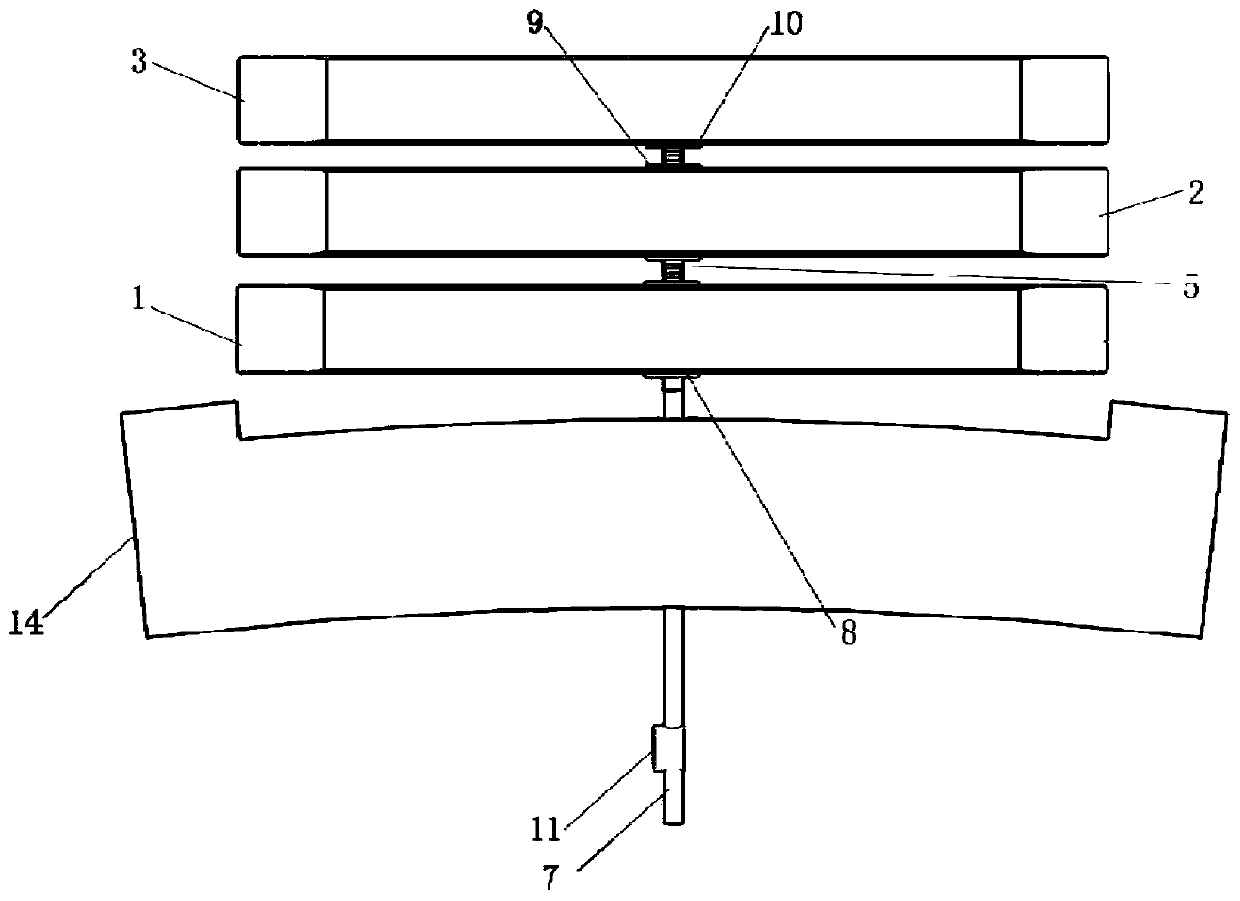

[0032] A stacked multi-layer rubber bladder that can meet the needs of large gaps, including an inner rubber bladder 1, a rubber bladder 2 that can be stacked in the middle, an outer rubber bladder 3, an outer rubber bladder heart bladder 4, an inflatable tube 5, and the outlet is unidirectional Valve 6, extension tube 7, inner bladder sealing gasket 8, middle bladder sealing gasket 9, outer bladder sealing gasket 10, inflation tube pressure gauge 11, outlet check valve pressure gauge 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com