Cross-hole rapid construction method for roller compacted concrete dam

A technology of roller compacted concrete and construction method, which is applied in dams, water conservancy projects, marine engineering and other directions, can solve the problems of quality and safety that cannot be effectively solved in rapid construction, low reliability, and insufficient concrete pouring, so as to shorten the construction period. The effect of construction period, ensuring construction quality, prefabrication and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

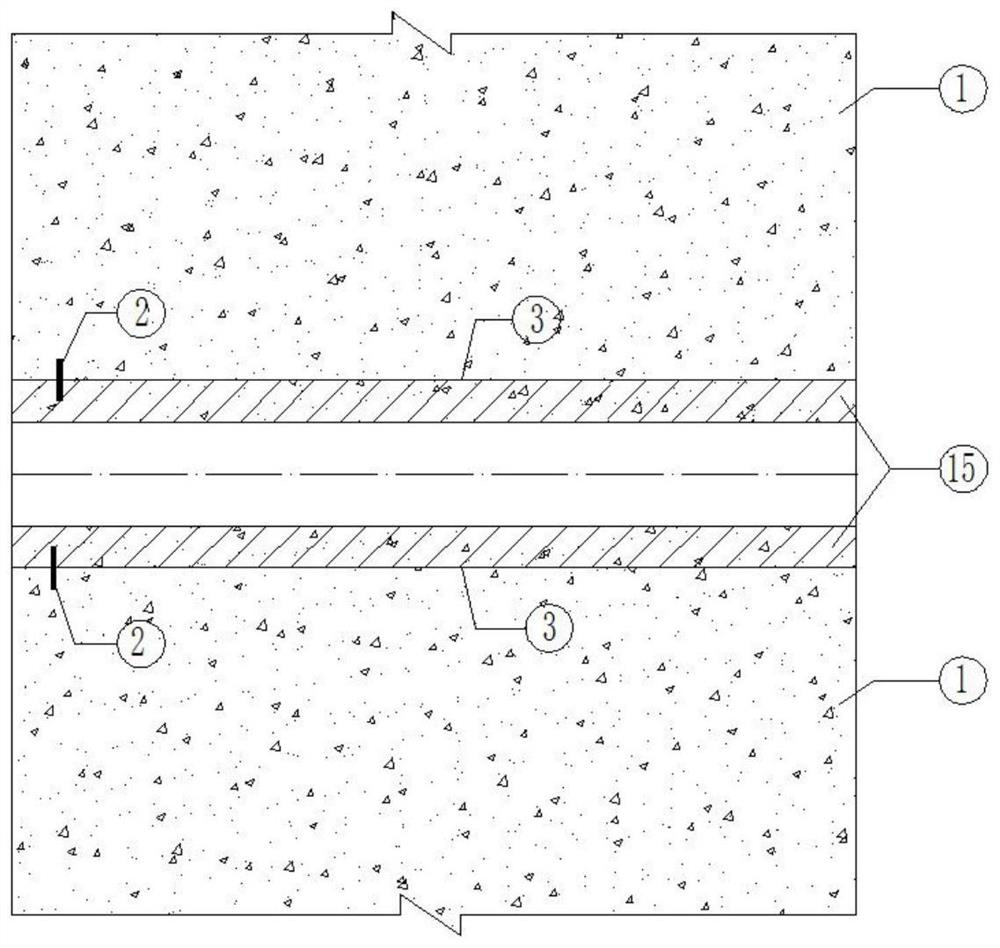

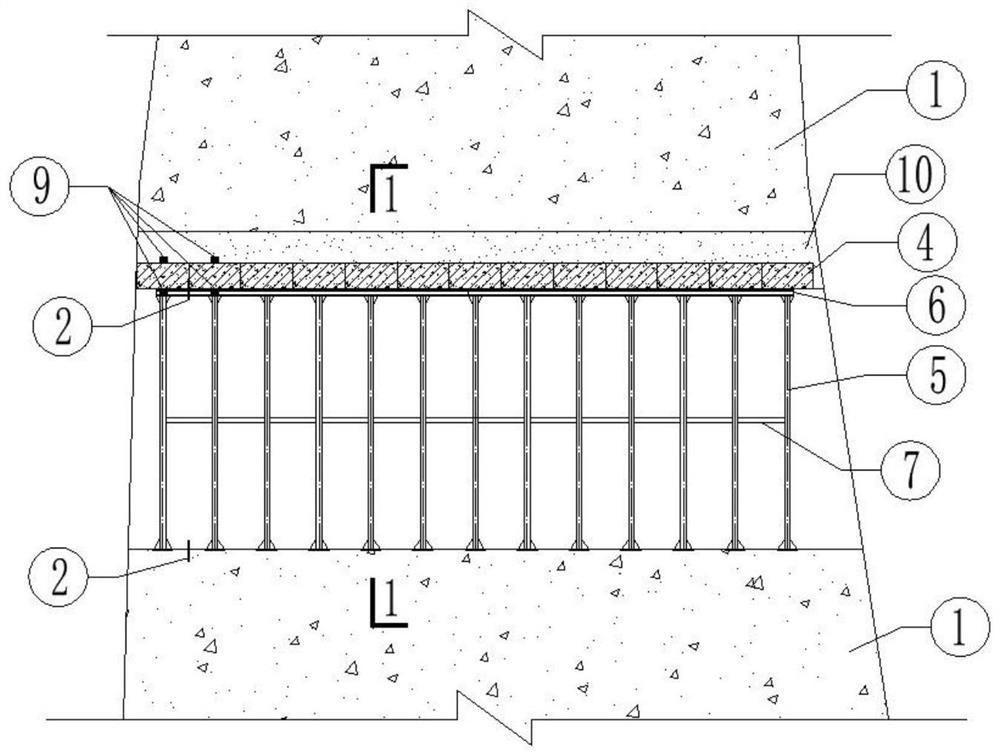

[0040] like Figure 1 to Figure 7 As shown, a kind of roller compacted concrete dam span-hole rapid construction method of the present invention comprises the following main steps:

[0041] Step 1. According to the width of the dam body hole structure 3, prefabricated concrete slab 4 is made in advance; when in use, the width of the dam body hole structure 3 is 4.5m, and the size of the precast concrete slab 4 is designed to be 7.5m×1m×0.5m (length x width x height).

[0042] Step 2. When the dam body roller compacted concrete 1 is constructed to the height of the dam body hole structure 3 bottom plate, the dam body hole structure 3 is reserved on the left and right sides of the design position of the dam body hole structure 3, and the dam body is rolled. Concrete 1 continues to rise as a whole, and copper water stop 2 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com