Preparation method of cage by embedded grade granular PEEK

A technology of intervertebral fusion device and polyetheretherketone, applied in bone implants, medical science, prostheses, etc., can solve the problems of chip scrapping, high cost, and low production efficiency, and meet the requirements of high strength and high plasticity Requirements, large elastic limit force, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

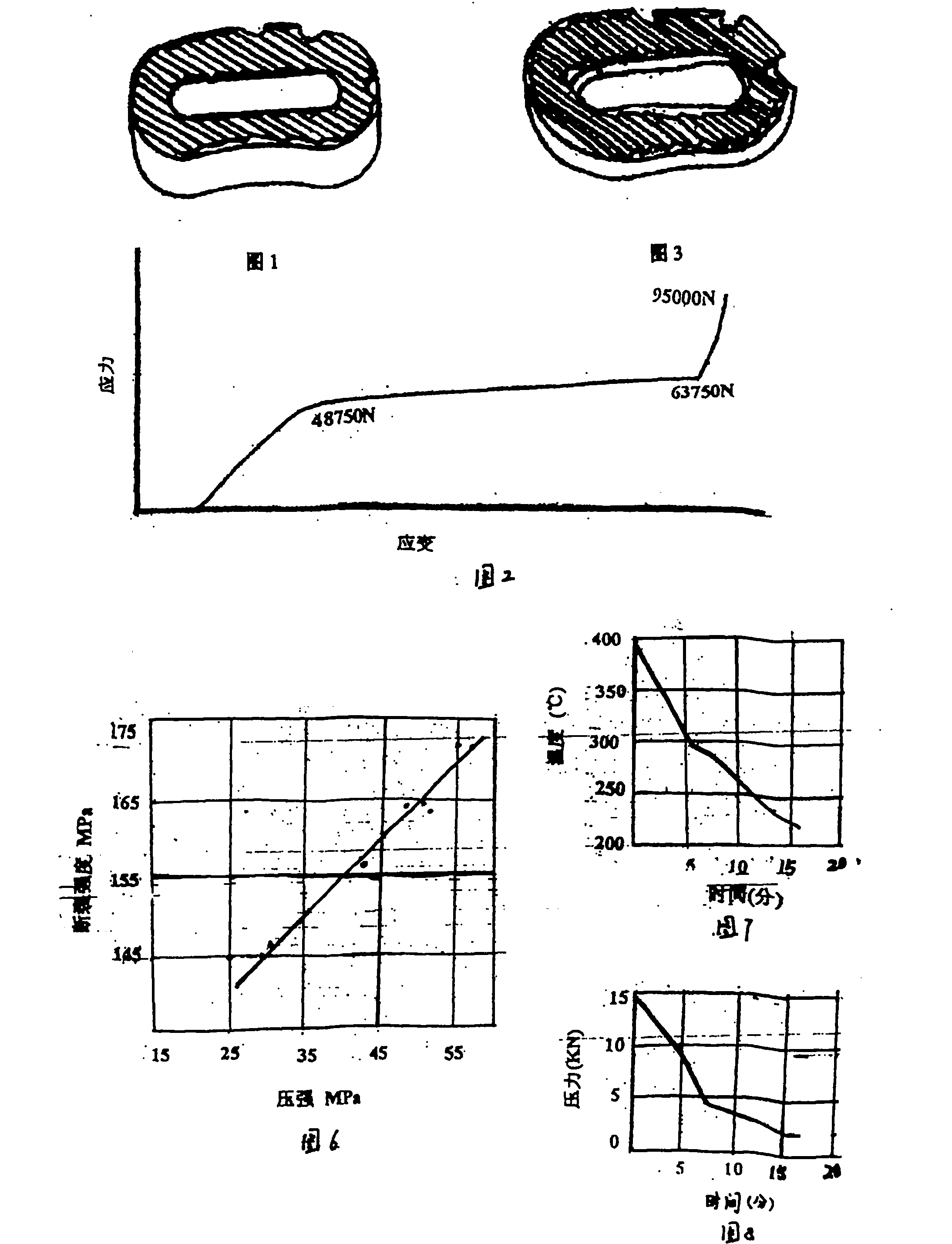

[0035] A method for preparing an intervertebral fusion device with implantable-grade granular polyether ether ketone, comprising the steps of:

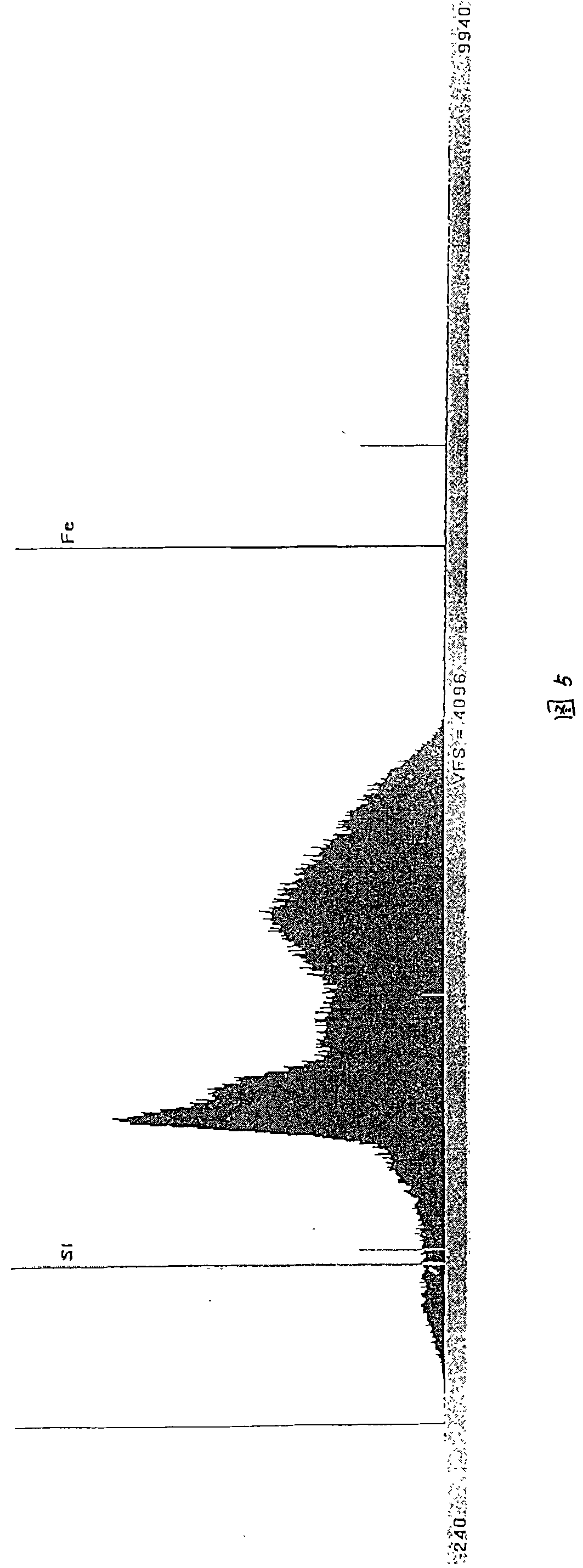

[0036] Step 1: The mold is made of high-chromium medium-carbon heat-resistant steel, tempered at 400-410°C after quenching, and the hardness is ≥ Rc.40. Ultrasonic cleaning with distilled water and chemical pure ethanol before use, and placed in a 100,000-level clean room before cleaning, dried and placed in a 10,000-level clean box for loading.

[0037] Step 2: Rapidly raise the temperature of the mold and the polyetheretherketone inside to 390°C. The heating time from 340℃ to 390℃ is: anterior cervical ≤4 minutes, lumbar posterior ≤4 minutes, lumbar anterior ≤6 minutes, heat preservation: anterior cervical 2 minutes, lumbar posterior 2 minutes, lumbar anterior 3 minute.

[0038] Step 3: Pressurize after heat preservation to eliminate the granular boundary of polyether ether ketone. Pressure: 50Mpa on the front of the neck, 50Mpa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic limit | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com