Negative electrode for lithium secondary battery and lithium secondary battery containing the same

A lithium secondary battery and negative electrode technology, which is applied in the structural field of current collectors and active material layers, can solve the problems of current collector fracture, current collector wrinkling, negative electrode degradation, etc., and achieve the effect of suppressing wrinkles and improving cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

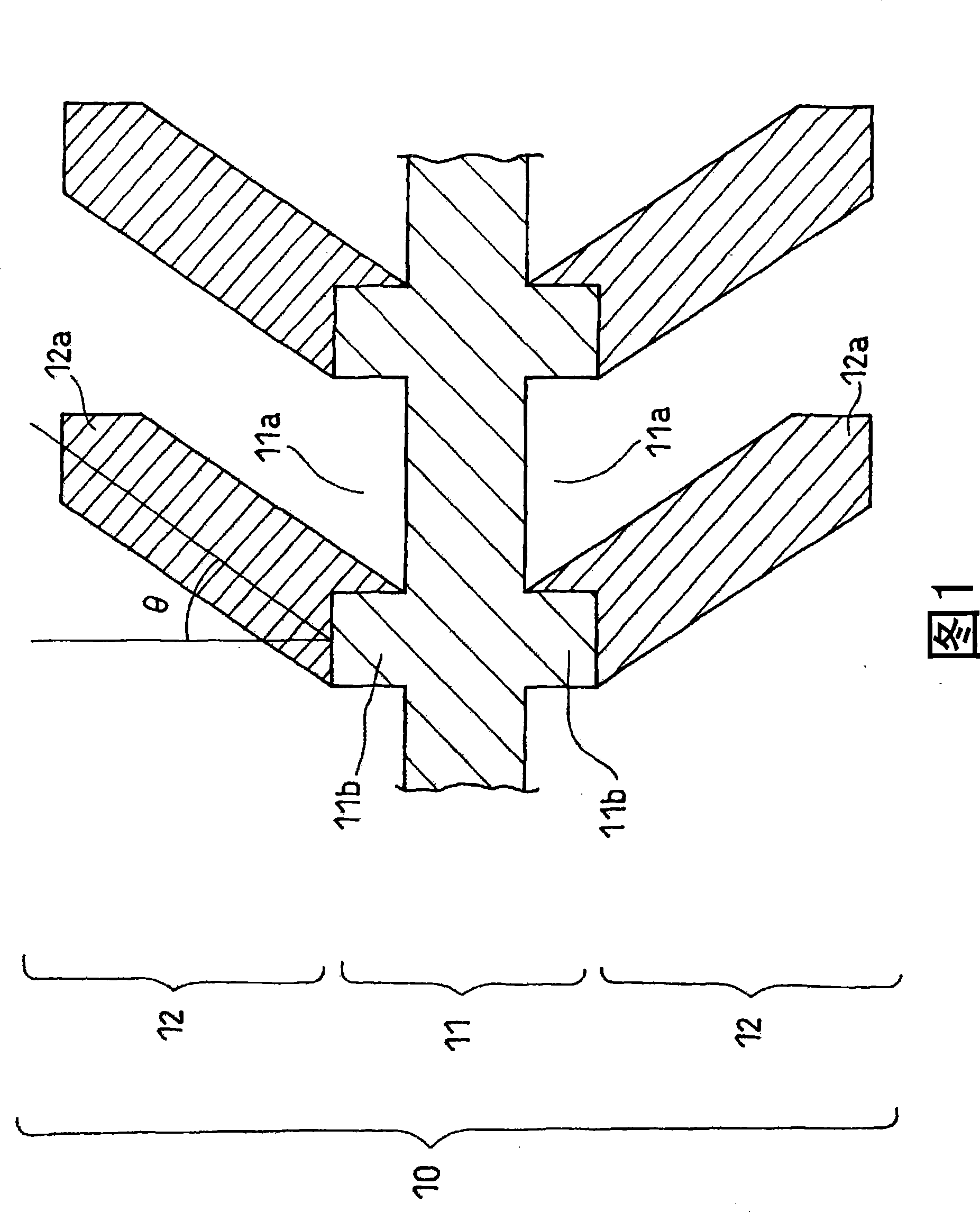

Embodiment 1

[0178] A laminated lithium secondary battery as shown in FIG. 11 was fabricated.

[0179] (I) Preparation of positive electrode

[0180] Fully mix 10 g of positive electrode active material, that is, lithium cobaltate (LiCoO) with an average particle size of 10 μm. 2 ) powder, 0.3g conductive agent namely acetylene black, 0.8g binder namely polyvinylidene fluoride powder, appropriate amount of N-methylpyrrolidone (NMP), and prepare positive electrode mixture slurry.

[0181] The obtained slurry was coated on one side of a positive electrode current collector made of an aluminum foil having a thickness of 20 μm, followed by drying and rolling to form a positive electrode active material layer. Next, the obtained positive electrode sheet was cut into a predetermined shape to obtain a positive electrode. The positive electrode active material layer carried on one side of the current collector had a thickness of 70 μm and a size of 14.5 mm×14.5 mm. A positive electrode lead mad...

Embodiment 2

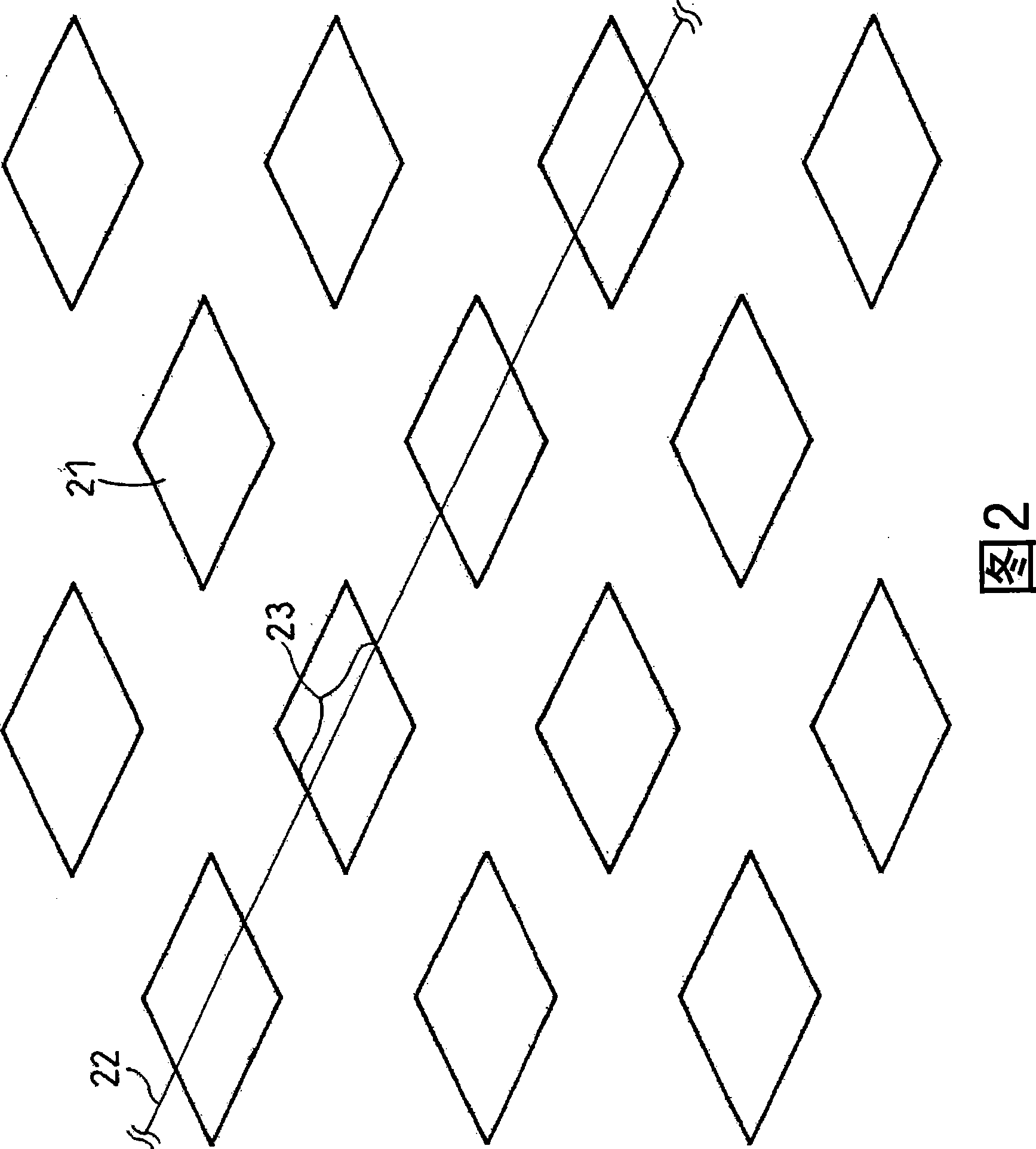

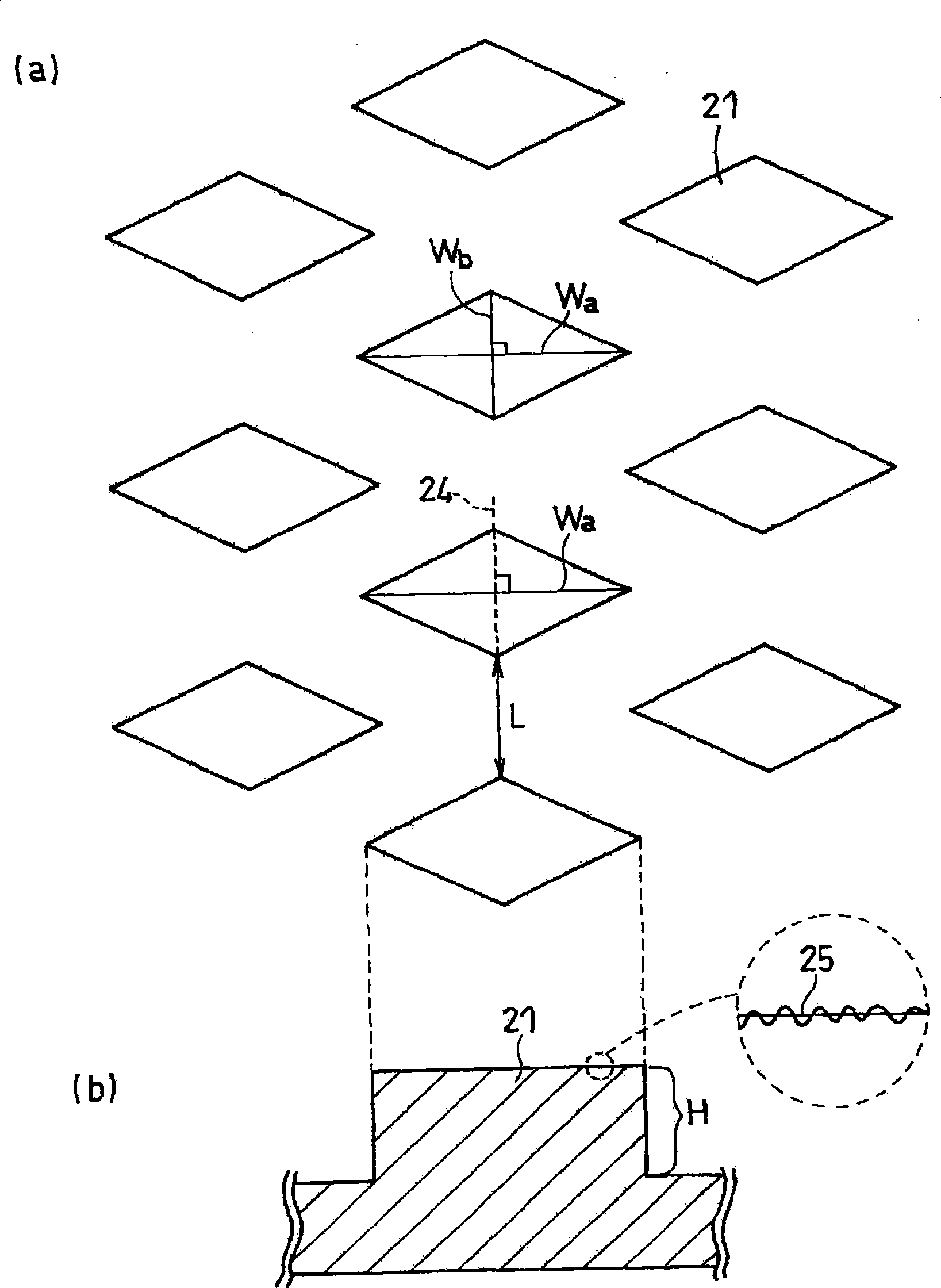

[0266] Next, an experiment was performed to find an appropriate size range by changing the size of the protruding region. Negative electrodes 2A to 2D were produced in the same manner as in Example 1 except that the pattern of the protruding regions provided on the current collector was changed as follows and the negative electrode active material layer was changed as follows. Batteries 2A to 2D were produced in the same manner as in Example 1 except that negative electrodes 2A to 2D were used.

[0267] (I) Negative electrode 2A

[0268] Set the shape of the cross-section of the protruding area to W a 8μm, W b A rhombus of 10 μm. along the largest diameter W a The distance L between adjacent protruding regions in the vertical direction was 18 μm. The height H of the protruding region was 6 μm. Except for this, a negative electrode current collector 2A was produced in the same manner as in Example 1.

[0269] In addition, in the negative electrodes 2B to 2D, the maximum ...

Embodiment 3

[0295] Next, an experiment was performed to find an appropriate range of the area ratio and the line segment ratio of the protruding region.

[0296]The area ratio and line segment ratio of the protruding regions were adjusted by changing the distance L between the protruding regions adjacent in the direction perpendicular to the maximum diameter Wa.

[0297] The patterns of the rhombic protruding regions provided on the current collectors were changed as follows to prepare negative electrodes 3A to 3D. Batteries 3A to 3D were produced in the same manner as in Example 1 except that negative electrodes 3A to 3D were used.

[0298] (I) negative electrode 3A

[0299] In addition to specifying the shape of the cross-section of the protruding region as W a 20μm, W b Negative electrode current collector 3A was produced in the same manner as in Example 1, except that the distance L between the protruding regions was 7 μm and the height H of the protruding regions was 3.5 μm, excep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| apparent porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com