Method for correcting output power of online optical head

A technology of output power and correction method, applied in the direction of optical recording/reproduction, optical recording head, beam source, etc., can solve problems such as misalignment, programming failure, power supply instability, etc., to increase stability, increase The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

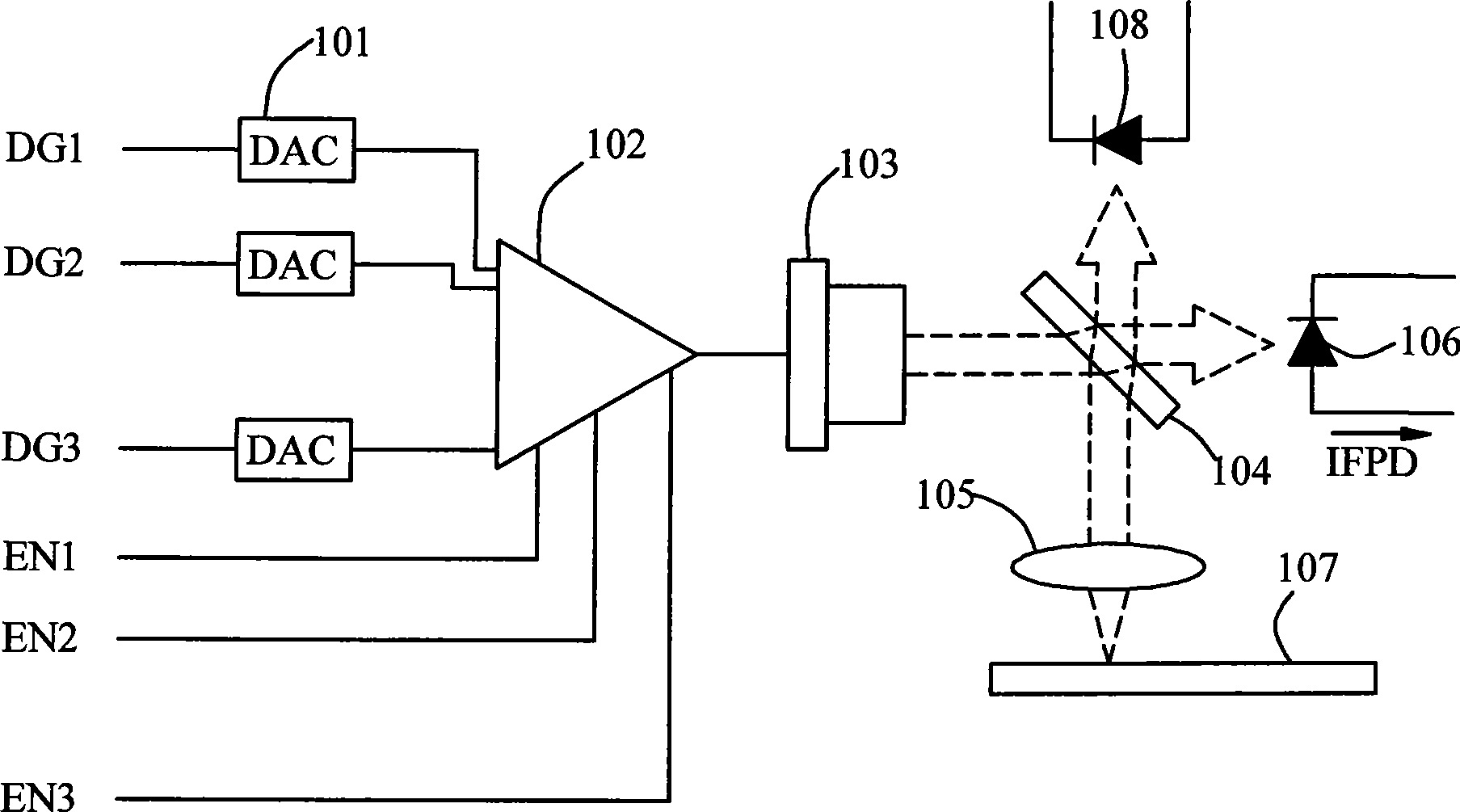

Method used

Image

Examples

Embodiment Construction

[0028] Due to the unstable supply voltage of the existing system or the aging of the optical head, the output power of the optical head will be inaccurate. Therefore, in order to solve this problem, the present invention uses a mechanism. Before burning, the online output power is calibrated, and in order to increase the calibration speed and not damage the disc, defocusing is not performed in this method. The following will be described with examples.

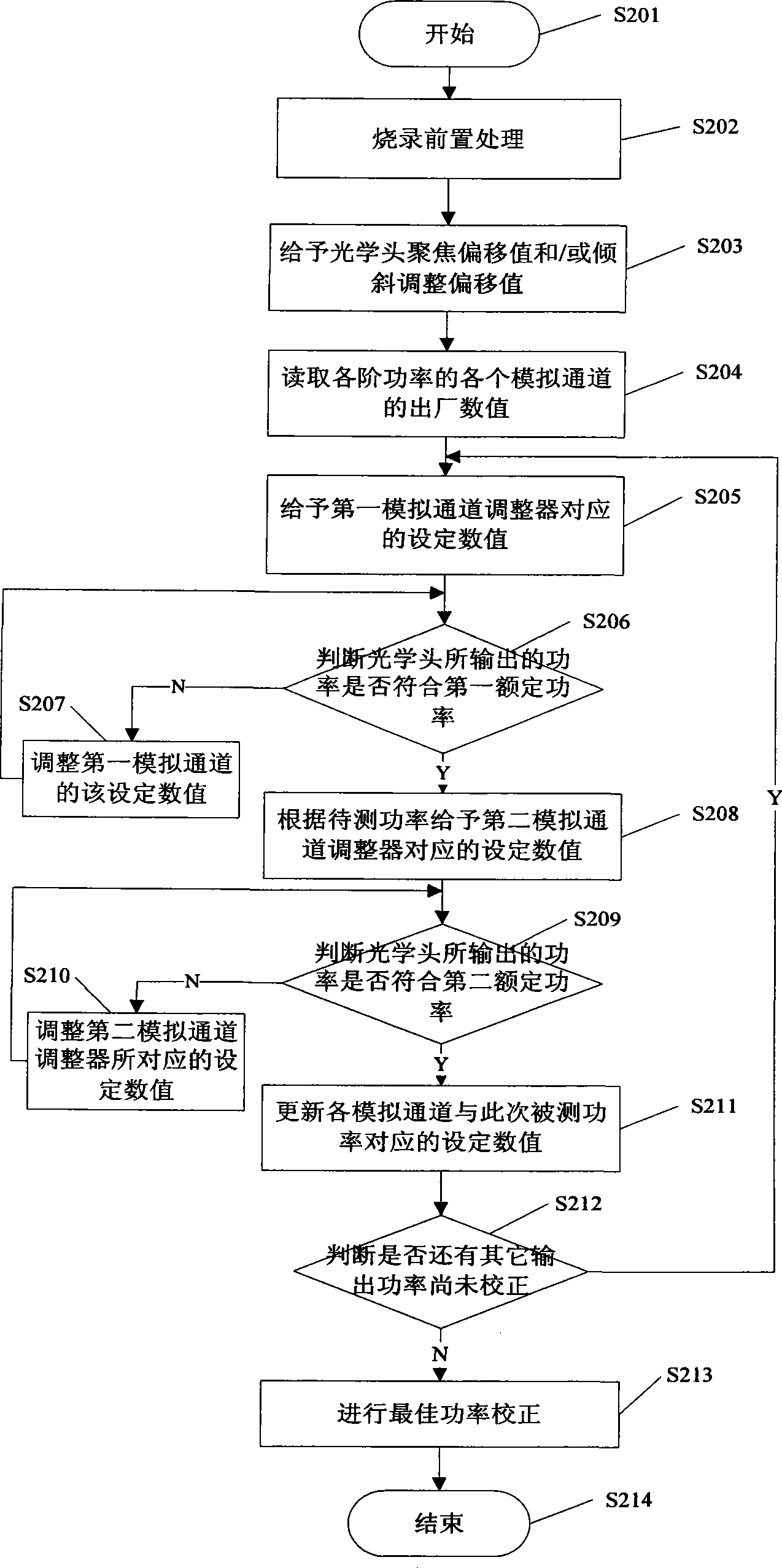

[0029] figure 2 It is a flowchart of an online output power calibration method according to an embodiment of the present invention. Please refer to figure 2 , before explaining this method, it is assumed that this method uses the power correction performed before burning the optical disc. This online output power calibration method includes the following steps:

[0030] Step S201: start;

[0031] Step S202: burning pre-processing;

[0032] For example, to focus on the optical disc or to correct the tilt angle of the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com