Transfer pipe for zinc alloy melt and manufacturing method thereof

A zinc alloy and pipeline technology, applied in pipeline protection, pipeline damage/wear prevention, pipes, etc., can solve problems such as large heat loss, pollution of alloy liquid, long contact time, etc., to reduce oxidation rate, reduce oxidation slag, reduce The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

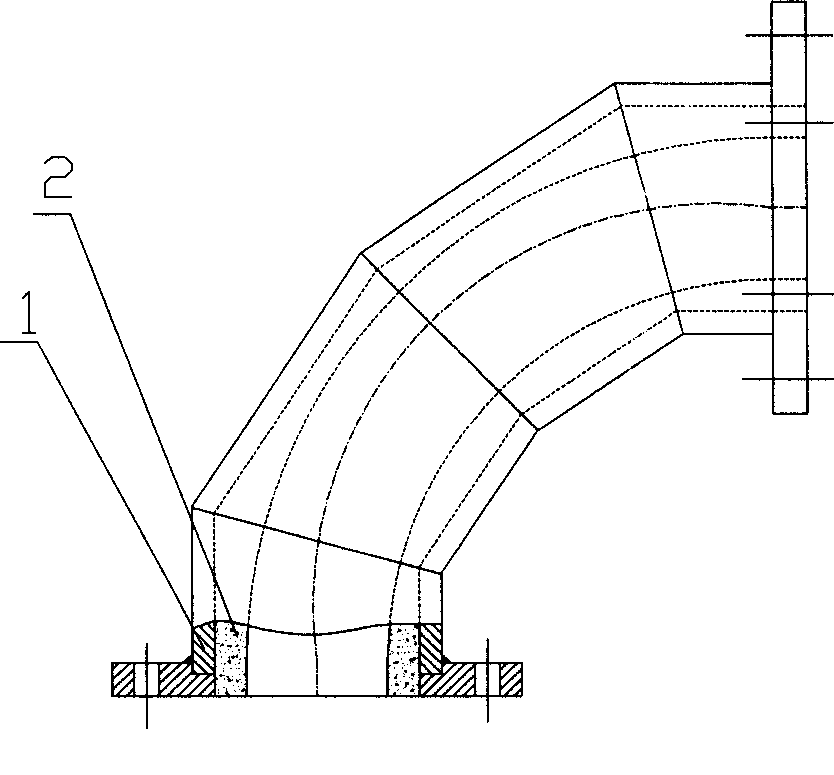

[0022] Such as figure 1 , figure 2 Shown, a kind of zinc alloy liquid conveying pipeline, it is lined with a layer of lining layer 2 made of refractory material at the inner surface of steel pipe 1, and inner lining layer 2 is the refractory material layer directly stamped on the inner surface of steel pipe. The refractory material layer is made of solid material plus glass water to make a slurry. The composition and weight ratio of the solid material are: 65% of burnt gemstone aggregate, 34.9% of high alumina powder, and 0.1% of sodium fluorosilicate , The weight ratio of the glass water is 5% of the solid material.

[0023] The specific process is as follows: the first step is to design and manufacture an easy-to-burn mold with the inner diameter of the required pipe, and fix it in the center of the pipe; the second step is to prepare the refractory material slurry and tamp the refractory material to fill the inner surface of the pipe In the space between the refractory m...

Embodiment 2

[0025] Such as figure 1 , figure 2 Shown, a kind of zinc alloy liquid conveying pipeline, it is lined with a layer of lining layer 2 made of refractory material at the inner surface of steel pipe 1, and inner lining layer 2 is the refractory material layer directly stamped on the inner surface of steel pipe. The refractory material layer is made of solid material plus glass water to make a slurry. The composition and weight ratio of the solid material are: 75% of burnt gemstone aggregate, 24.2% of high alumina powder, and 0.8% of sodium fluorosilicate , The weight ratio of the glass water is 15% of the solid material.

[0026] The specific process is as follows: the first step is to design and manufacture an easy-to-burn mold with the inner diameter of the required pipe, and fix it in the center of the pipe; the second step is to prepare the refractory material slurry and tamp the refractory material to fill the inner surface of the pipe In the space between the refractory ...

Embodiment 3

[0028] Such as image 3 As shown, a zinc alloy liquid conveying pipeline is lined with an inner lining layer made of a refractory material 2 on the inner surface of a steel pipe 1, and the inner lining layer is an integral refractory material pipe 3 inserted in the steel pipe 1 and The structure fixed on the inner surface of the steel pipe 1 is tamped and fixed by the refractory material 2 .

[0029] Concrete manufacturing process is: the first step, selects the refractory material pipe that the mullite that has formed is made, and it is coaxially fixed in the center of pipeline, second step, prepares refractory material slurry, (with embodiment 1 Same) ramming and filling refractory material between the pipeline and the refractory material pipeline, so that the refractory material pipeline and the inner surface of the steel pipe are rammed and fixed into one, and the thickness of the refractory material is greater than 20 mm. The third step is to dry naturally at room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com