Method for dry method etching polycrystalline silicon in deep plow groove

A dry etching, polysilicon technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as excessive polysilicon gaps and increased polysilicon surface roughness, to eliminate gap expansion and reduce etching. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the manufacturing process of the power MOS device, in order to form a double-layer polysilicon gate structure in the deep trench, in one embodiment of the present invention, the following method can be used:

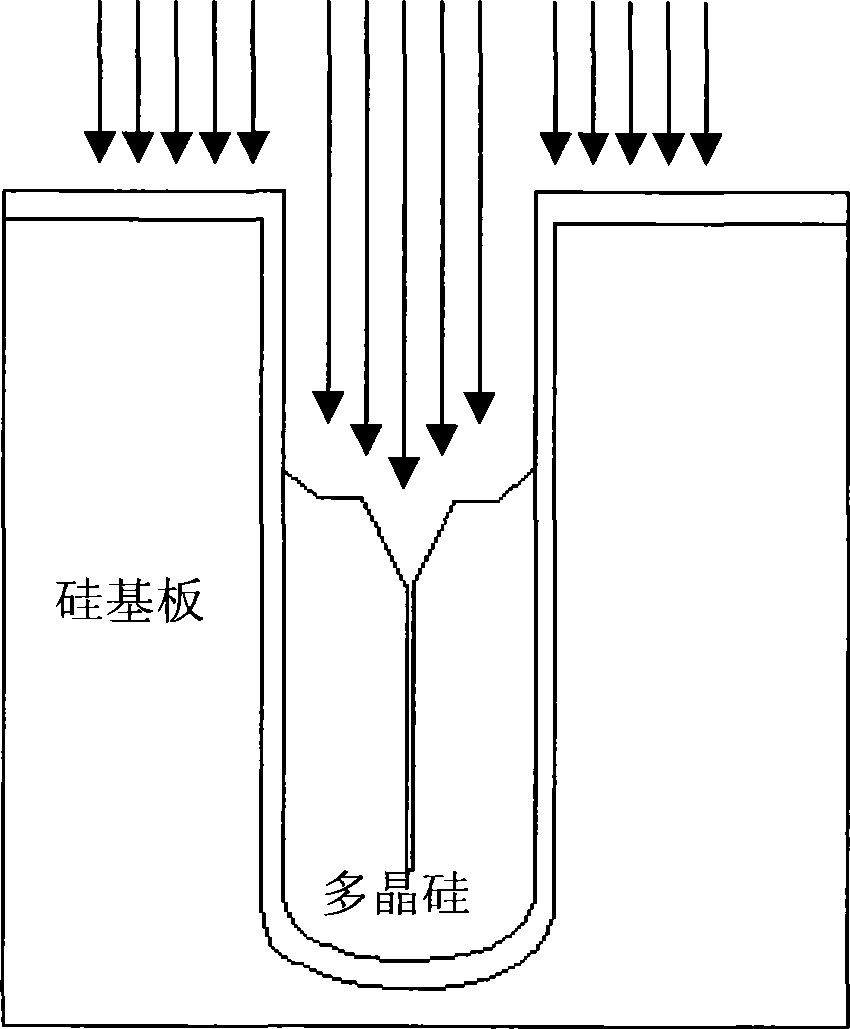

[0014] In the first step, using existing processes, a layer of Thick polysilicon to fill up the deep trench, then the structure diagram of the device is as follows figure 1 shown.

[0015] The second step is to use chlorine, hydrogen bromide and oxygen, and perform the first dry etching on the polysilicon deposited in the deep trench with a lower power of 20-200W, so as to remove the polysilicon on the surface and part of the trench polysilicon, then the structure diagram of the device is as follows figure 2 shown.

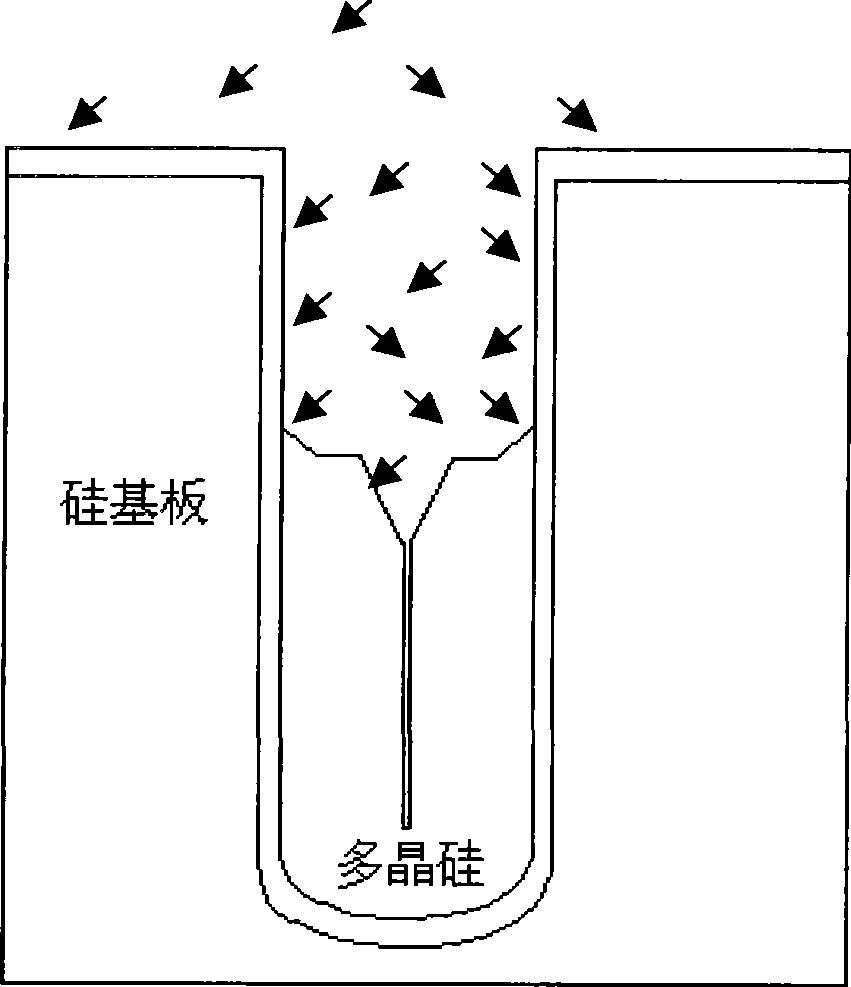

[0016] The third step, as mentioned above, due to the above-mentioned first dry etching, the polysilicon has the disadvantages of larger gaps and higher surface roughness, so in the present invention, as image 3 shown, and then carbon tetraf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com