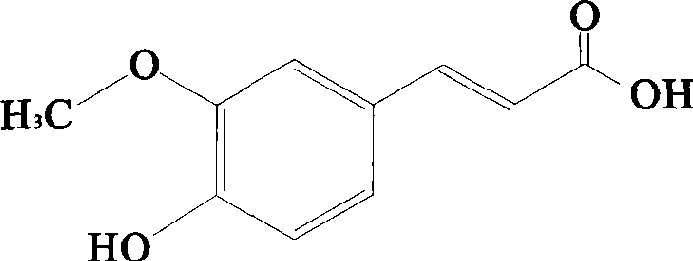

Preparation of natural ferulaic acid

A technology of ferulic acid and ferulic acid ester, applied in the field of preparation of natural ferulic acid, can solve the problems of increasing production cost, lengthening process flow, being insoluble in water, etc., saving production cost, improving production environment, The effect of omitting the consumption of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

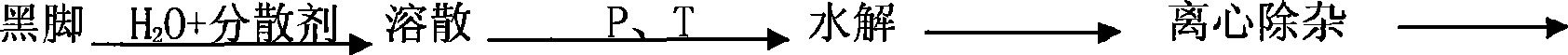

Method used

Image

Examples

Embodiment 1

[0021] Take 1000kg of the by-product commonly known as black feet produced in the production process of rice bran oil. Its ferulic acid ester content is 34.25%, which is equivalent to 10.96% of ferulic acid content. , add 230kg of 30% liquid caustic soda, 4kg of fatty acid sodium, heat with steam, pressurize 0.2Mpa, stir, when the solution temperature rises to 110°C, stop heating, continue to pressurize and stir for 4 hours, the black foot dissolves and hydrolyzes. Cool the hydrolyzate, remove insoluble impurities by a centrifuge to obtain an aqueous solution of ferulic acid, acidify the solution, and thus precipitate ferulic acid. The concentration of dilute sulfuric acid used is 10-30%, and the pH value of the aqueous solution is 1. ~4. When the temperature of the solution reaches 25-30°C, the acidification and precipitation of ferulic acid is completed, and the aqueous solution containing ferulic acid is filtered to obtain 104.5kg of crude ferulic acid, and the crude ferulic...

Embodiment 2

[0023] Repeat the operation of embodiment 1, change fatty acid sodium in embodiment 1 into fatty acid potassium, ferulic acid ester content is 33.64%, is equivalent to the content of ferulic acid and is 10.61%, the add-on of fatty acid potassium is 10kg, finally gets Ferulic acid crude product 98.7kg. Refined to obtain 86.8kg of pure product ferulic acid.

Embodiment 3

[0025] Repeat the operation of Example 1, change the fatty acid sodium in Example 1 into fatty acid lithium, the ferulic acid ester content is 34.66%, is equivalent to ferulic acid content and is 10.83%, and the add-on of fatty acid lithium is 5kg, final ferulic acid Ferulic acid crude product 104kg, refined to obtain pure product ferulic acid 83.2Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com