A kind of preparation method of granular coated cobalt powder

A technology of coating cobalt powder and granular, which is applied in the field of preparation of granular coated cobalt powder, which can solve the problem of poor strength of granular coated cobalt powder, poor fluidity of granular coated cobalt powder, and inability to apply automatic feeding and other problems, to achieve the effect of avoiding high-temperature drying process, round and smooth appearance, and saving airflow crushing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The embodiment of the present invention provides a preparation method of granular coated cobalt powder, comprising the following steps:

[0020] S01. Provide spongy cobalt powder;

[0021] S02. The spongy cobalt powder is sequentially subjected to controlled crushing treatment and first sieving treatment to obtain granular cobalt powder with a particle size of 30-80 mesh;

[0022] S03. After preheating the granular cobalt powder, heating and mixing the granular cobalt powder and the molten coating agent and then cooling to obtain prefabricated granular coated cobalt powder;

[0023] S04. The prefabricated granular coated cobalt powder is subjected to drum granulation and second sieving treatment to obtain granular coated cobalt powder.

[0024] Specifically, in the above-mentioned step S01, the spongy cobalt powder is the precursor of the conventionally used ultra-fine cobalt powder, and its price is low. Using it as a raw material can also save the airflow of using th...

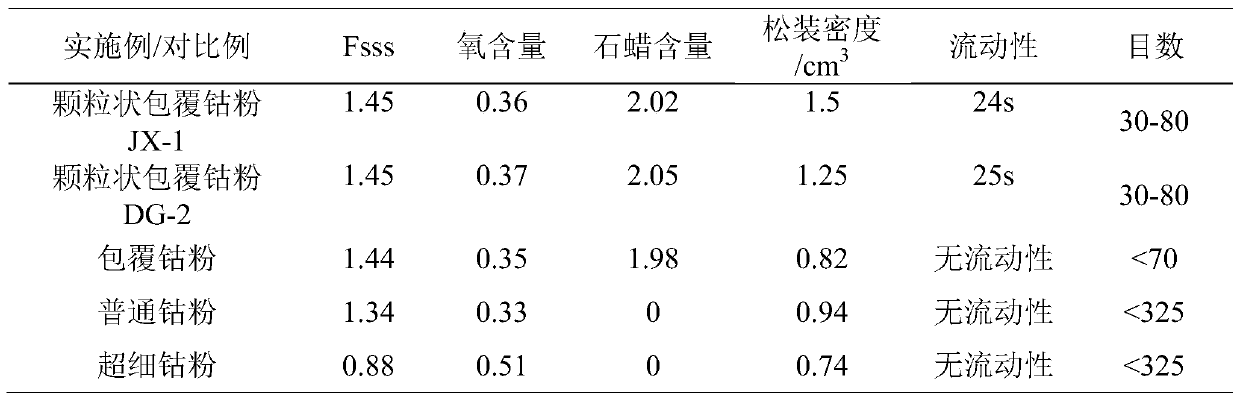

Embodiment 1

[0044] A preparation method of granular coated cobalt powder, comprising the following steps:

[0045] S01. Take FSSS as spongy cobalt powder of 1.45 μm;

[0046] S02. The spongy cobalt powder is sequentially subjected to controlled crushing and first sieving to obtain granular cobalt powder with a particle size of 30-80 mesh, wherein the frequency of the controlled crusher is set to 30 Hz;

[0047] S03. Add the granular cobalt powder into the planetary mixing tank, set the temperature of the circulating water at 58°C, preheat for 15 minutes under vacuum, then weigh paraffin wax with 2% cobalt powder, add the preheated cobalt after melting powder. The stirring speed was set at 10r / min, stirring and mixing under vacuum conditions for 50 minutes, then switching the circulating water to cooling water, and stirring and cooling for 25 minutes.

[0048] S04. Transfer the mixed cobalt powder from the mixing tank to the drum, and roll for 5 minutes to obtain granular cobalt powder w...

Embodiment 2

[0051] A preparation method of granular coated cobalt powder, comprising the following steps:

[0052] S01. Take FSSS as spongy cobalt powder of 1.45 μm;

[0053] S02. The spongy cobalt powder is sequentially crushed by pair of rollers for controlled crushing and first sieving to obtain granular cobalt powder with a particle size of 30-80 mesh, wherein the interval of the pair of rollers is 1-7mm ;

[0054] S03. Add the granular cobalt powder into the planetary mixing tank, set the temperature of the circulating water at 58°C, preheat for 15 minutes under vacuum, then weigh paraffin wax with 2% cobalt powder, add the preheated cobalt after melting powder. The stirring speed was set at 10r / min, stirring and mixing under vacuum conditions for 50 minutes, then switching the circulating water to cooling water, and stirring and cooling for 25 minutes.

[0055] S04. Transfer the mixed cobalt powder from the mixing tank to the drum, and roll for 5 minutes to obtain granular cobalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com