Method for preparing hollow nano gold powder material

A technology of hollow nano-bulk materials, which is applied in the field of preparation of hollow nano-gold powder materials, can solve the problems of complex preparation process, complex operation process, poor versatility, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

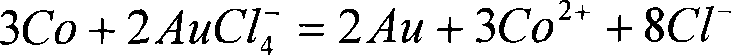

Method used

Image

Examples

Embodiment 1

[0016] Pass 300mL of deionized water through high-purity nitrogen to remove dissolved oxygen, add 31mg of sodium citrate and 340mg of sodium borohydride under stirring, so that the concentration of sodium citrate in the deionized water is 0.0004M, and the concentration of sodium borohydride is 0.03M. After stabilization, 224mg of cobalt acetate was added to make the concentration of cobalt acetate in deionized water 0.003M. The reaction system was always carried out under the protection of nitrogen. That is, cobalt nanoparticles with nanoscale were synthesized. Then continue to stir the reaction until the sodium borohydride in the system is completely consumed, add 247mg of chloroauric acid to make the concentration of chloroauric acid in deionized water 0.002M, and stir at room temperature for 6h. Finally, the product is centrifuged, washed, and vacuum-dried for 4 hours to obtain a hollow nano-gold powder material. The average particle size is 20nm and the inner diameter is...

Embodiment 2

[0018] Pass 300mL of deionized water through high-purity nitrogen to remove dissolved oxygen, add 39mg of sodium citrate, 680mg of sodium borohydride, and 448mg of cobalt acetate under stirring, so that the concentration of sodium citrate in the deionized water is 0.0005M, and the concentration of sodium borohydride is 0.06M, the concentration of cobalt acetate is 0.006M. The reaction system was carried out under the protection of nitrogen. That is, cobalt nanoparticles with nanoscale were synthesized. Then add 494mg of chloroauric acid to make the concentration of chloroauric acid in deionized water 0.004M, and stir at room temperature for 8h. Finally, the product was centrifuged, washed, and vacuum-dried for 6 hours to obtain a hollow nano-gold powder material. The average particle size is 35nm and the inner diameter is 29nm.

Embodiment 3

[0020] Pass 1000mL deionized water through high-purity nitrogen to get rid of dissolved oxygen, add sodium citrate 155mg, sodium borohydride 3404mg, cobalt acetate 2242mg under stirring, make the concentration of sodium citrate in deionized water be 0.0006M, the concentration of sodium borohydride is 0.09M, the concentration of cobalt acetate is 0.009M. . The reaction system was carried out under the protection of nitrogen. That is, cobalt nanoparticles with nanoscale were synthesized. Then add 2471mg of chloroauric acid to make the concentration of chloroauric acid in deionized water 0.006M, and stir at room temperature for 12h. Use sodium bicarbonate to adjust the pH value to 8. After the reaction is completed, the product is centrifuged, washed, and vacuum-dried for 10 hours to obtain a hollow nano-gold powder material. The average particle diameter is 50nm, and the inner diameter is 42nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com