Consistent grease for meter, gear and driving screw of airplane

A technology of aircraft instruments and transmission screws, which is applied in the field of lubricating grease, can solve the problems of low efficiency, complicated process, unsatisfactory low temperature performance of lubricating grease and rubber compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

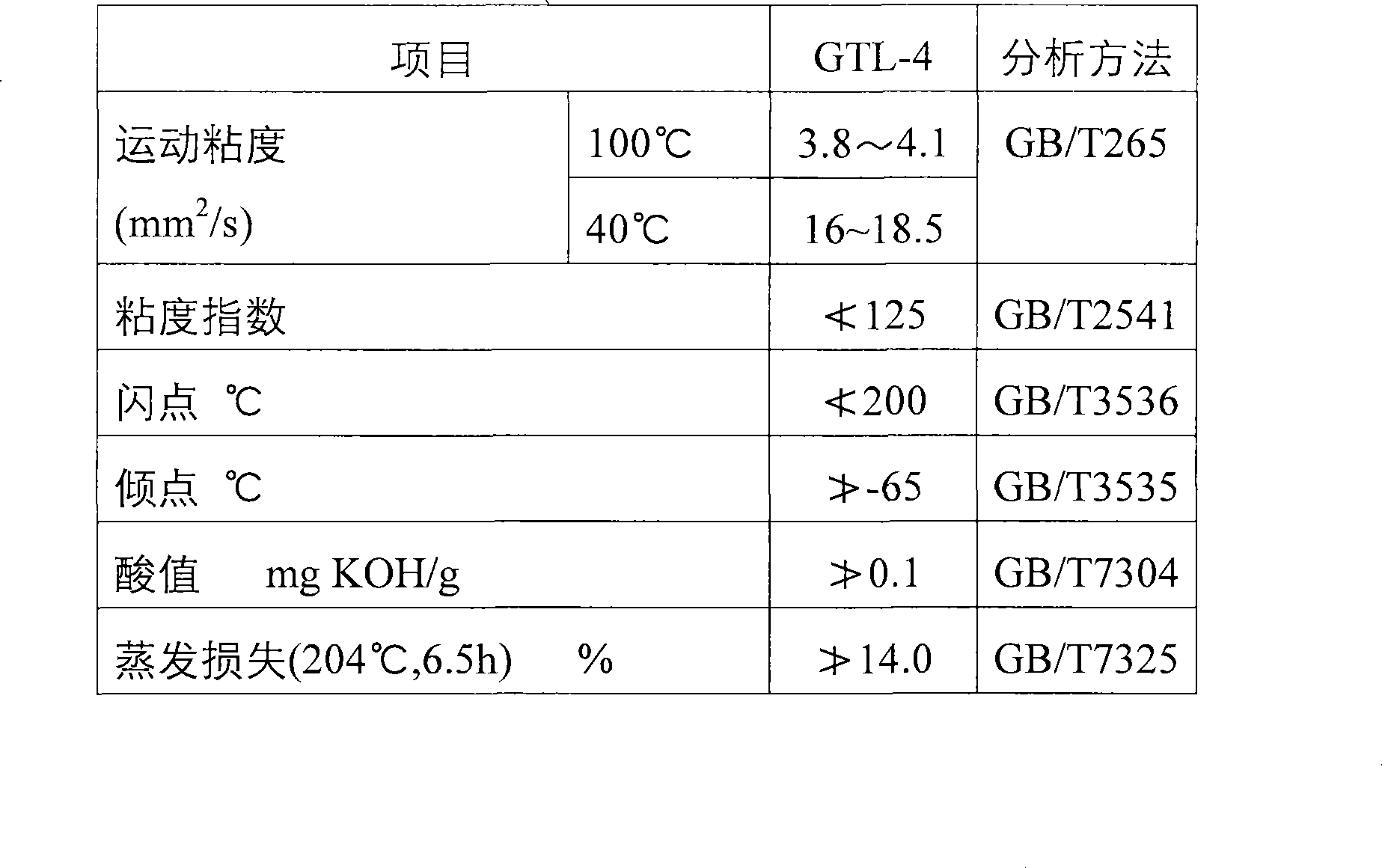

[0022] In a 100L atmospheric pressure kettle, add 30 kg of 100°C kinematic viscosity 4mm 2 / s of GTL base oil and 5 kg of lauryl hydroxystearic acid, heat and stir, the temperature rises to 87 ° C, add 0.7 kg of lithium hydroxide monohydrate aqueous solution, wherein the weight of water is 3.5 kg, saponification and dehydration, and heat up to 215 ℃, stop heating, add 15 kg of the same base oil as quenching oil. The temperature is lowered to 140°C, and the pressure is cut at 0.8 MPa for 30 minutes. When the temperature drops to 100°C, 1.5 kg of tricresyl phosphate, 0.15 kg of alkylated diphenylamine (liquid), and 0.05 kg of benzene Paratriazole and 1.0 kg of calcium lanolin, mixed evenly. Table 1 lists the viscosity of 4mm at 100°C 2 The physical and chemical performance indicators of GTL synthetic oil per s. The physical and chemical properties of the product are shown in Table 2.

Embodiment 2

[0024] In a 100L atmospheric pressure kettle, add 20 kg 2 / s of GTL base oil and 3 kg of lauryl hydroxystearic acid, heat and stir, the temperature rises to 82 ° C, add 0.44 kg of lithium hydroxide monohydrate aqueous solution, wherein the weight of water is 2.0 kg, heat up and stir, wait for water vapor After the volatilization is completed, the temperature in the kettle rises to 130°C, and 10 kg of the same base oil is added, and the temperature is raised to 200°C with continuous stirring, and the heating is stopped, and 15 kg of 100°C kinematic viscosity 8mm is added. 2 / s GTL base oil as quenching oil. The temperature is lowered to 130°C, and the pressure is cyclically sheared at 0.6MPa for 40 minutes. When the temperature drops to 90°C, 0.5 kg of tricresyl phosphate, 0.1 kg of alkylated diphenylamine (liquid), and 0.03 kg of benzene Paratriazole and 0.5 kg of lanolin calcium, mix well. The physical and chemical properties of the product are shown in Table 2.

Embodiment 3

[0026] In a 100L atmospheric pressure kettle, add 20 kg 2 / s of GTL base oil and 7.5 kg of lauryl hydroxystearic acid, heat and stir, the temperature rises to 90 ° C, add 1.05 kg of lithium hydroxide monohydrate aqueous solution, wherein the weight of water is 5.0 kg, heat up and stir, and wait for the water vapor After the volatilization is complete, the temperature in the kettle rises to 150°C and adds 10 kg of 100°C kinematic viscosity of 6mm 2 / s GTL base oil, continue to stir and heat up to 220°C, stop heating, add 15 kg of 100°C kinematic viscosity 6mm 2 / s GTL base oil as quenching oil. The temperature is lowered to 150°C, and the pressure is cyclically sheared at 0.5MPa for 50 minutes. When the temperature drops to 120°C, 1.8 kg of tricresyl phosphate, 0.7 kg of alkylated diphenylamine (liquid), and 0.08 kg of benzene Paratriazole and 1.5 kg of barium petroleum sulfonate, mixed evenly. The physical and chemical properties of the product are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com