Raw material formula for automotive glass surface protective film and method of producing the same

A technology for surface protection film and automotive glass, which is applied in coatings and other directions, can solve the problems of lack of bonding force between silicone and glass, lack of oil resistance, high porosity of coating, etc., so as to improve the clarity of sight and reduce the damage to the human body , the effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

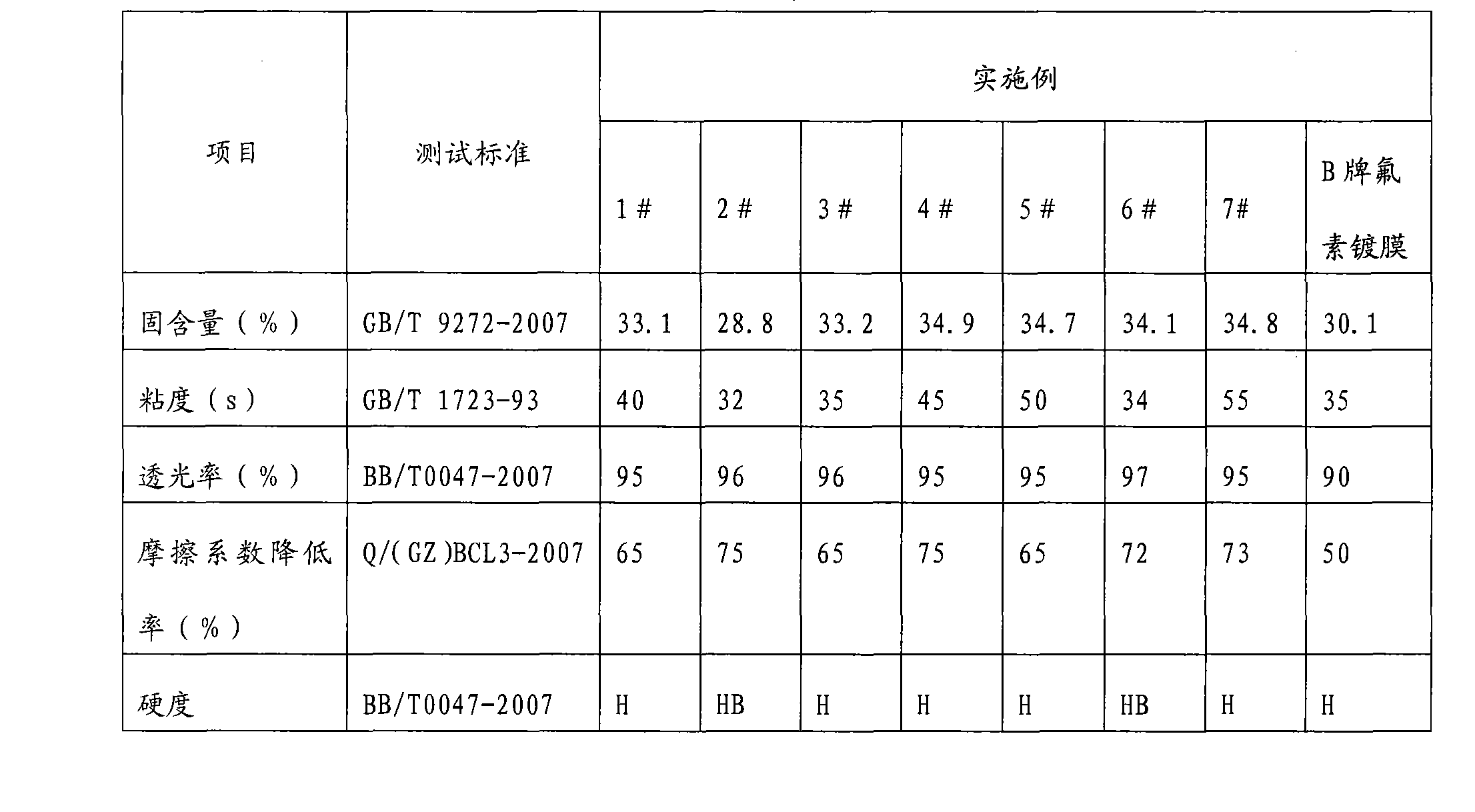

Examples

Embodiment Construction

[0029] The preparation method of the ethyl acrylate modified polytetrafluoroethylene automotive glass surface protective film of the present invention is as follows:

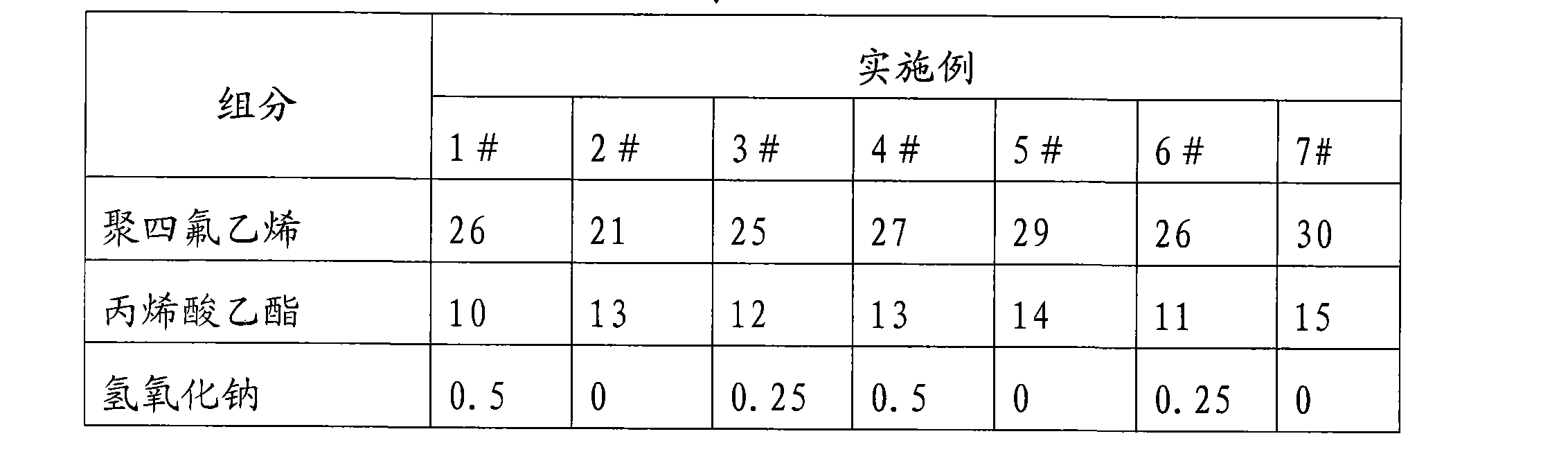

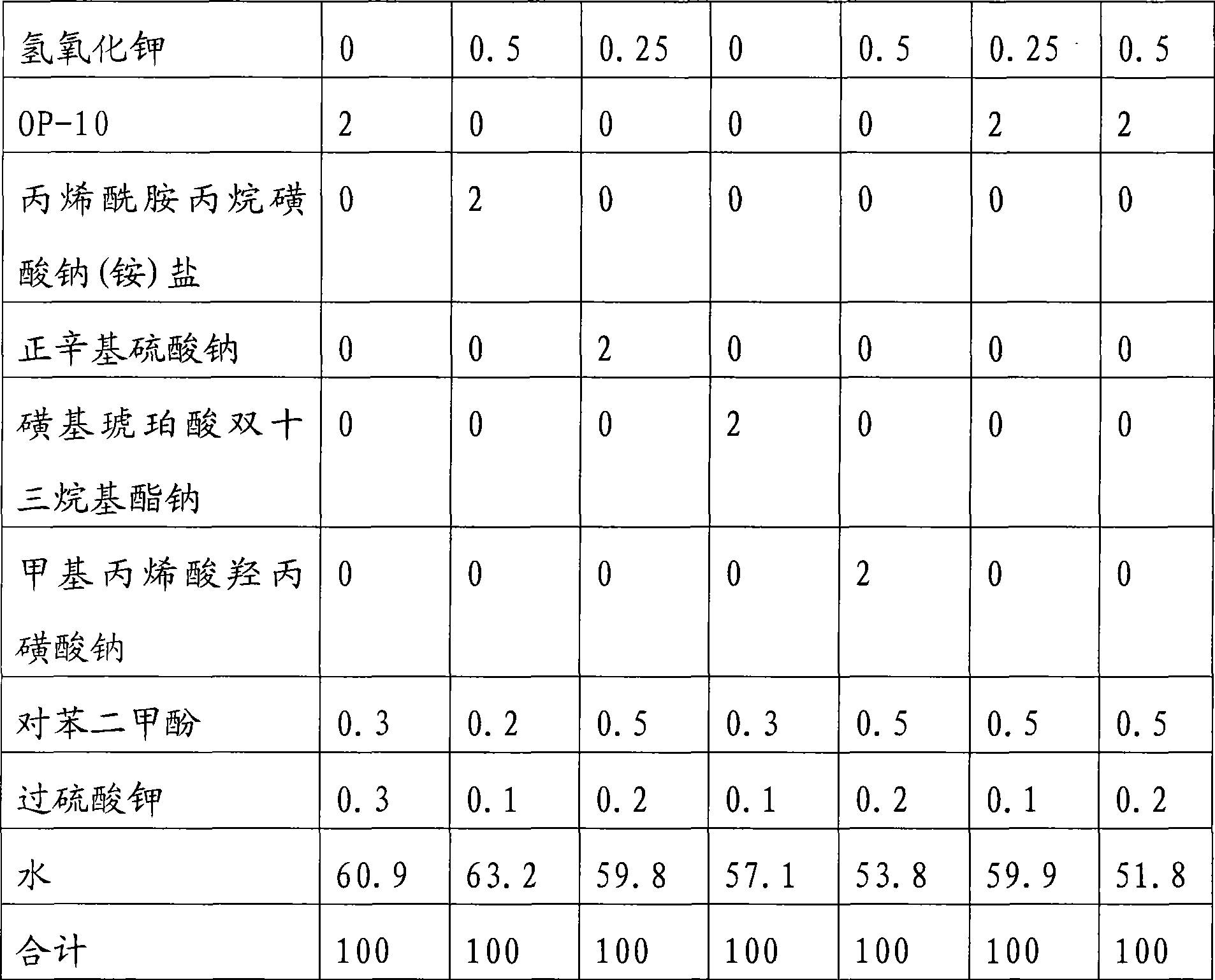

[0030] (1) Weigh polytetrafluoroethylene, ethyl acrylate, catalyst, emulsifier, and water, wherein polytetrafluoroethylene is polytetrafluoroethylene with iodine active end groups, and its degree of polymerization is 4 to 6, and its molecular weight is 20 to 20. 600,000, the ratio of polytetrafluoroethylene, water and ethyl acrylate is about 1:1.7~3:0.4~0.6.

[0031] (2) reacting polytetrafluoroethylene and water at 120-140 degrees Celsius in the presence of a catalyst for 2-4 hours;

[0032] (3) then add ethyl acrylate and react at 110~118 degrees Celsius for 1~2 hours;

[0033] (4) adding an emulsifier for homogeneous emulsification to obtain the final product.

[0034] The ethyl acrylate in the step (3) is the active ethyl acrylate blocked by the sealing agent, which is added dropwise to the polytetrafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com