Preparation method of up-conversion fluorescent glass for solar cells

A technology of solar cells and fluorescent glass, which is applied in circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as inability to actually form product applications, reduced sunlight transmittance, and low luminous efficiency of fluorescent particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

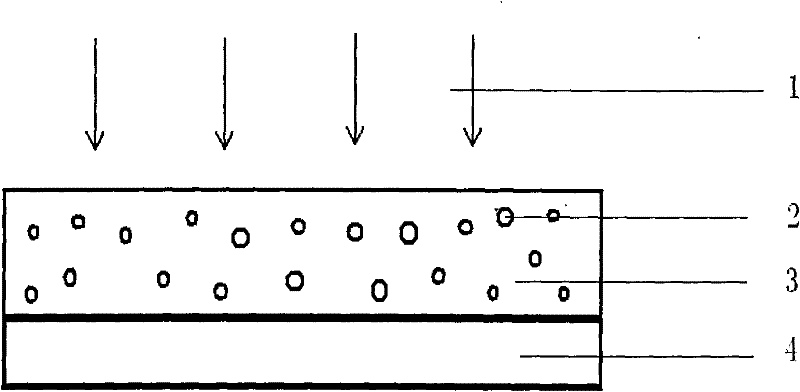

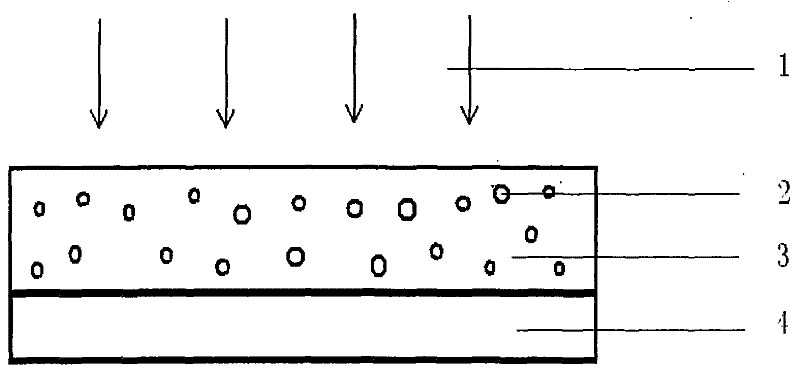

[0013] A method for preparing up-conversion fluorescent glass for solar cells includes: up-conversion phosphor material (2) and colorless transparent glass material for solar cells; mixing up-conversion phosphor and transparent glass material at a weight ratio of 1:50-200 It is uniform and made into flat colorless transparent glass (3), which is sealed on the front surface of the solar cell (4). When the ratio of up-conversion phosphor is large, the conversion efficiency is high, and the light transmittance is low; conversely, when the proportion of up-conversion phosphor is small, the conversion efficiency is low, and the light transmittance is high; the best ratio of up-conversion phosphor and transparent glass material is 1:100.

[0014] When sunlight (1) irradiates the up-conversion fluorescent glass on the surface of the solar cell, the near-infrared light 800-1600 nm in the sunlight can be converted into visible light, which is absorbed by the solar cell, thereby improving ...

Embodiment 1

[0023] Take 1 kg of the up-conversion phosphor material, soak it in an aqueous solution containing tetraethyl orthosilicate for 2 hours, take it out and dry it, and make the surface covered with a silicon dioxide film.

[0024] The above materials are fully mixed with 100 kilograms of silicate glass powder material, and the temperature is above 600 degrees to make up-conversion fluorescent flat glass.

[0025] The up-conversion fluorescent flat glass covering the surface of the solar cell can increase the photoelectric conversion efficiency by 2%.

Embodiment 2

[0027] Take 10 grams of the up-conversion phosphor material, soak it in an aqueous solution containing butyl titanate for 1 hour, take it out and dry it, and make its surface wrap the titanium dioxide film.

[0028] The above materials are mixed with 1500 grams of epoxy resin and cured at a temperature of 100 degrees to make up-conversion fluorescent flat epoxy glass.

[0029] The up-conversion fluorescent flat resin glass is encapsulated on the surface of the solar cell, and the photoelectric conversion efficiency can be improved by 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com