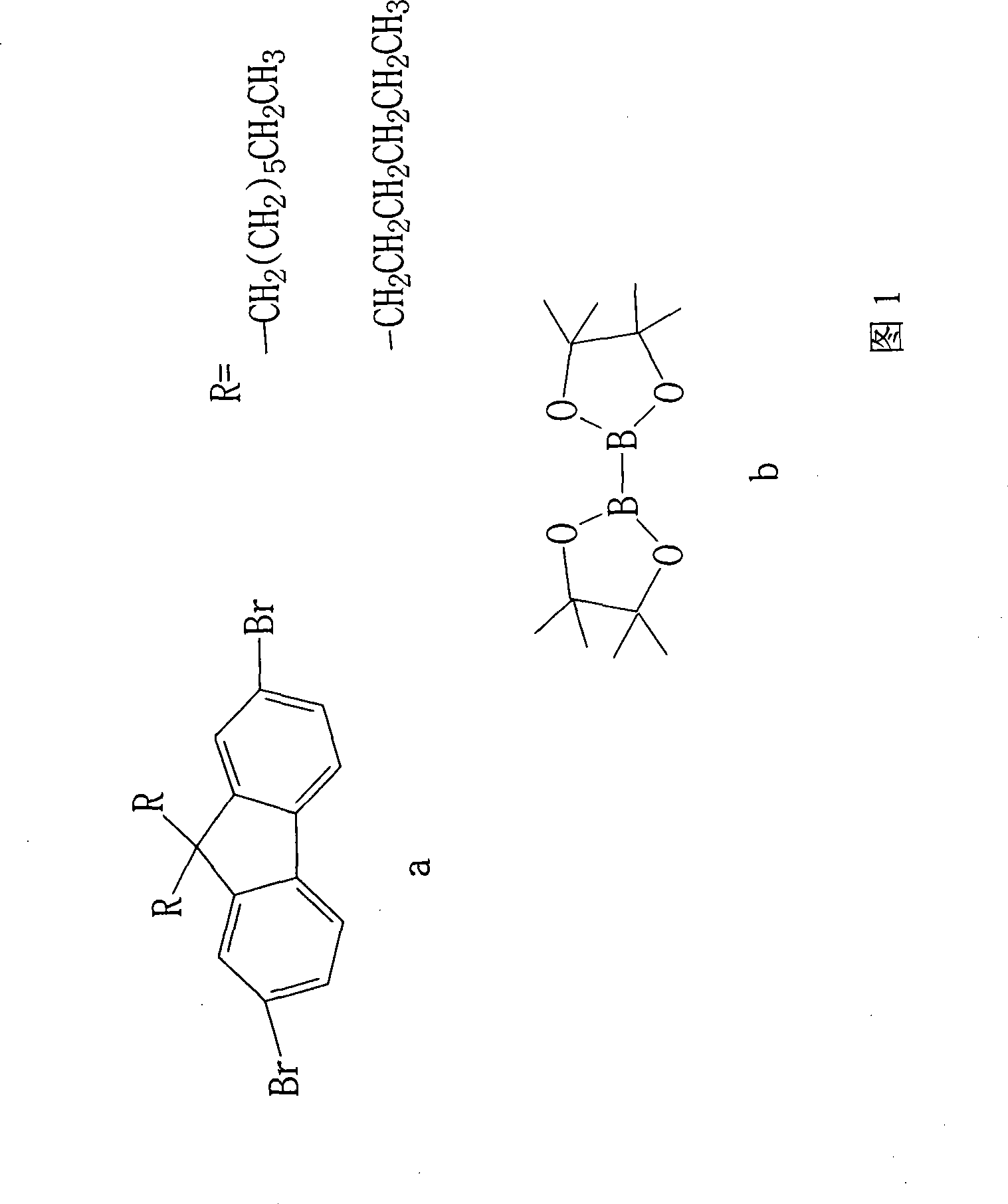

Synthesis of esterifiable fluorene diborate

A synthesis method and the technology of dialkyl diboronic esters are applied in the field of new method synthesis of dialkyl diboronic esterified fluorene monomers, which can solve the problems of unsuccessful synthesis of diboronic esters, increased difficulty of experiments, and problems in experiments. Harsh conditions and other problems, to achieve the effect of great practical value, simple post-processing, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

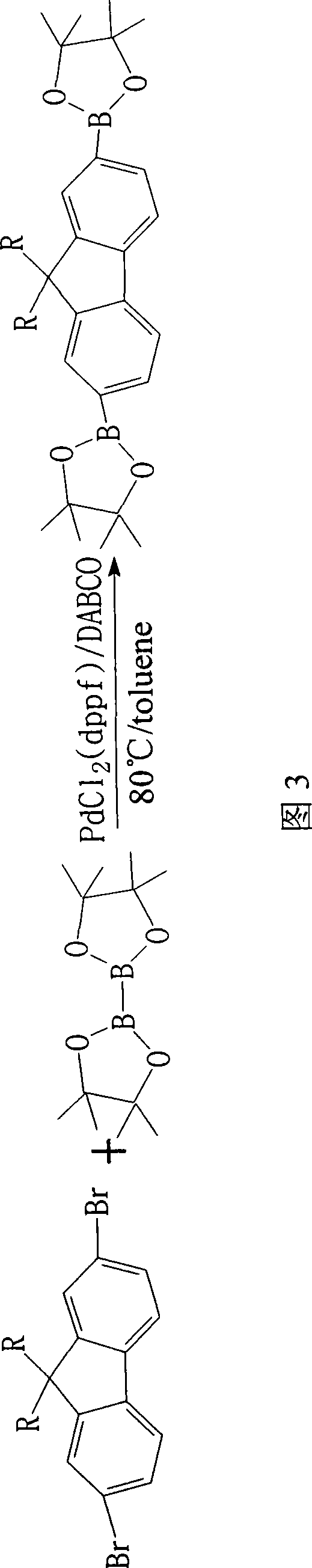

Method used

Image

Examples

Embodiment 1

[0025] Reactant 2,7-dibromo-9,9-dioctylfluorene and catalyst PdCl 2 The molar ratio of (dppf) is: 1:6%

[0026] Catalyst PdCl 2 The molar ratio of (dppf) to DABCO is: 1:16

[0027] Add 2mmol 2,7-dibromo-9,9-dioctylfluorene, 4.4mmol double pinacol borate 12%mmolPdCl in a 100ml four-necked flask equipped with a thermometer and a magnetic stirrer 2 (dppf), 192% mmol DABCO, 12 mmol potassium acetate and 10 ml toluene, vacuumize and feed nitrogen, and continuously stir and react for 4 h under the condition of heating in an oil bath at 80°C. The organic layer was separated, the aqueous layer was extracted several times with toluene, the organic layers were combined, and the organic layer was washed several times with water, then dried with anhydrous magnesium sulfate, and then passed through a column (silica gel as the solid phase, toluene as the mobile phase), and the Evaporate the solvent to dryness with an evaporator to obtain a crude product as a pale yellow solid, and finall...

Embodiment 2

[0029] Reactant 2,7-dibromo-9,9-dioctylfluorene and catalyst PdCl 2 The molar ratio of (dppf) is: 1:6%

[0030] Catalyst PdCl 2 The molar ratio of (dppf) to DABCO is: 1:20

[0031] Add 2mmol 2,7-dibromo-9,9-dioctylfluorene, 4.4mmol double pinacol borate 12%mmolPdCl in a 100ml four-necked flask equipped with a thermometer and a magnetic stirrer 2 (dppf), 240% mmol DABCO, 12 mmol potassium acetate and 10 ml toluene were vacuumed and nitrogen gas was introduced, and the reaction was continuously stirred for 4 h under the condition of heating in an oil bath at 80°C. The organic layer was separated, the aqueous layer was extracted several times with toluene, the organic layers were combined, and the organic layer was washed several times with water, then dried with anhydrous magnesium sulfate, and then passed through a column (silica gel as the solid phase, toluene as the mobile phase), and the Evaporate the solvent to dryness with an evaporator to obtain a crude product as a pa...

Embodiment 3

[0033] Reactant 2,7-dibromo-9,9-dioctylfluorene and catalyst PdCl 2 The molar ratio of (dppf) is: 1:4%

[0034] Catalyst PdCl 2 The molar ratio of (dppf) to DABCO is: 1:4

[0035]Add 2mmol 2,7-dibromo-9,9-dioctylfluorene, 4.4mmol double pinacol borate 8%mmolPdCl to a 100ml four-necked flask equipped with a thermometer and a magnetic stirrer 2 (dppf), 32% mmol DABCO, 12 mmol potassium acetate and 10 ml toluene, vacuumize and blow in nitrogen, and continuously stir and react for 6 h under the condition of heating in an oil bath at 80°C. The organic layer was separated, the aqueous layer was extracted several times with toluene, the organic layers were combined, and the organic layer was washed several times with water, then dried with anhydrous magnesium sulfate, and then passed through a column (silica gel as the solid phase, toluene as the mobile phase), and the Evaporate the solvent to dryness with an evaporator to obtain a crude product as a pale yellow solid, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com