High-conversion ratio method and equipment for producing chlorine dioxide

A chlorine dioxide, high conversion technology, applied in the direction of chlorine oxide and other directions, can solve the problems of increasing the disinfection cost of tap water, the ratio of raw materials deviates from the theoretical value, and the conversion rate of chlorine dioxide is low, so as to reduce the cost of human resources and management, The effect of reducing raw material consumption and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

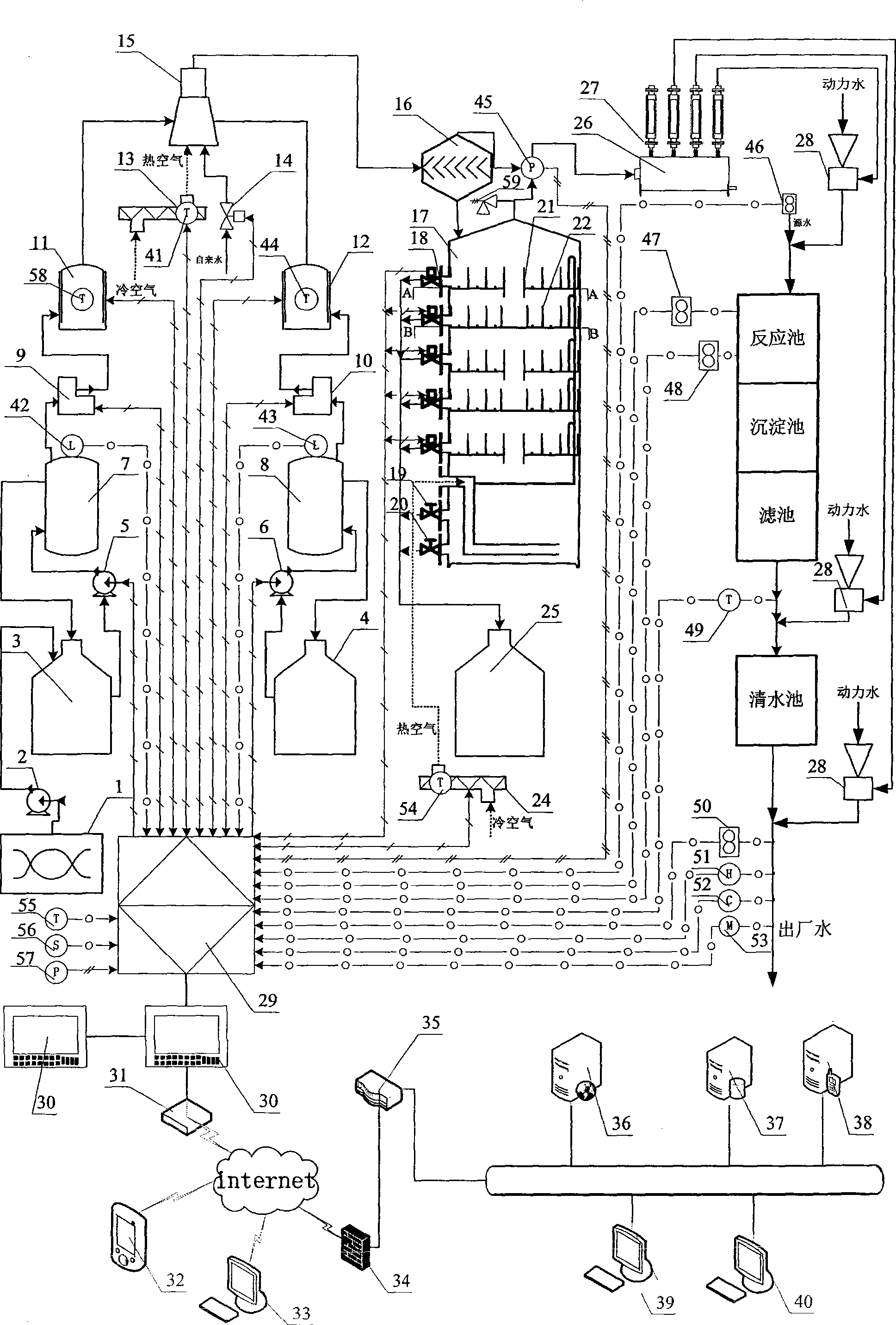

Method used

Image

Examples

Embodiment 1

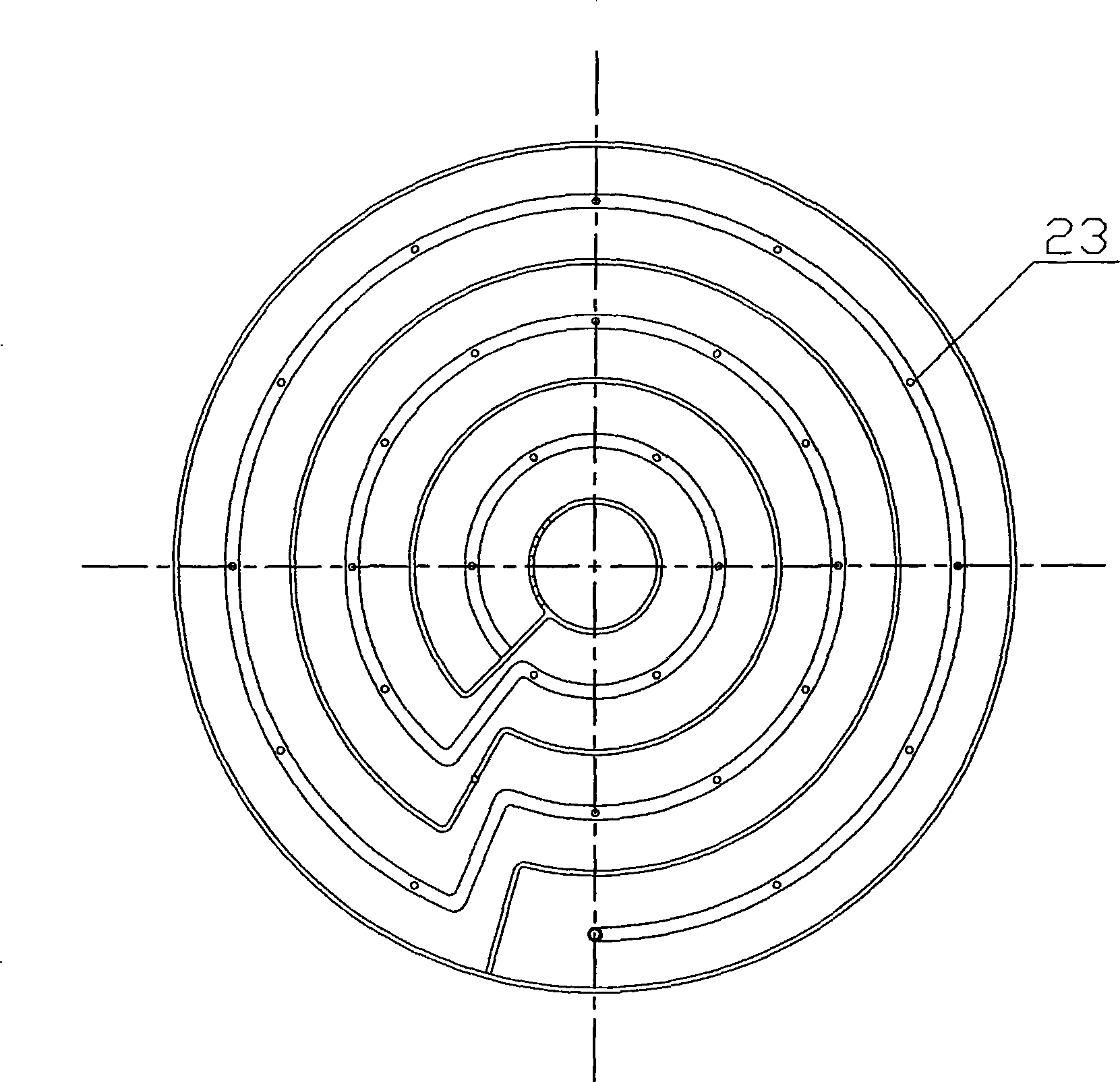

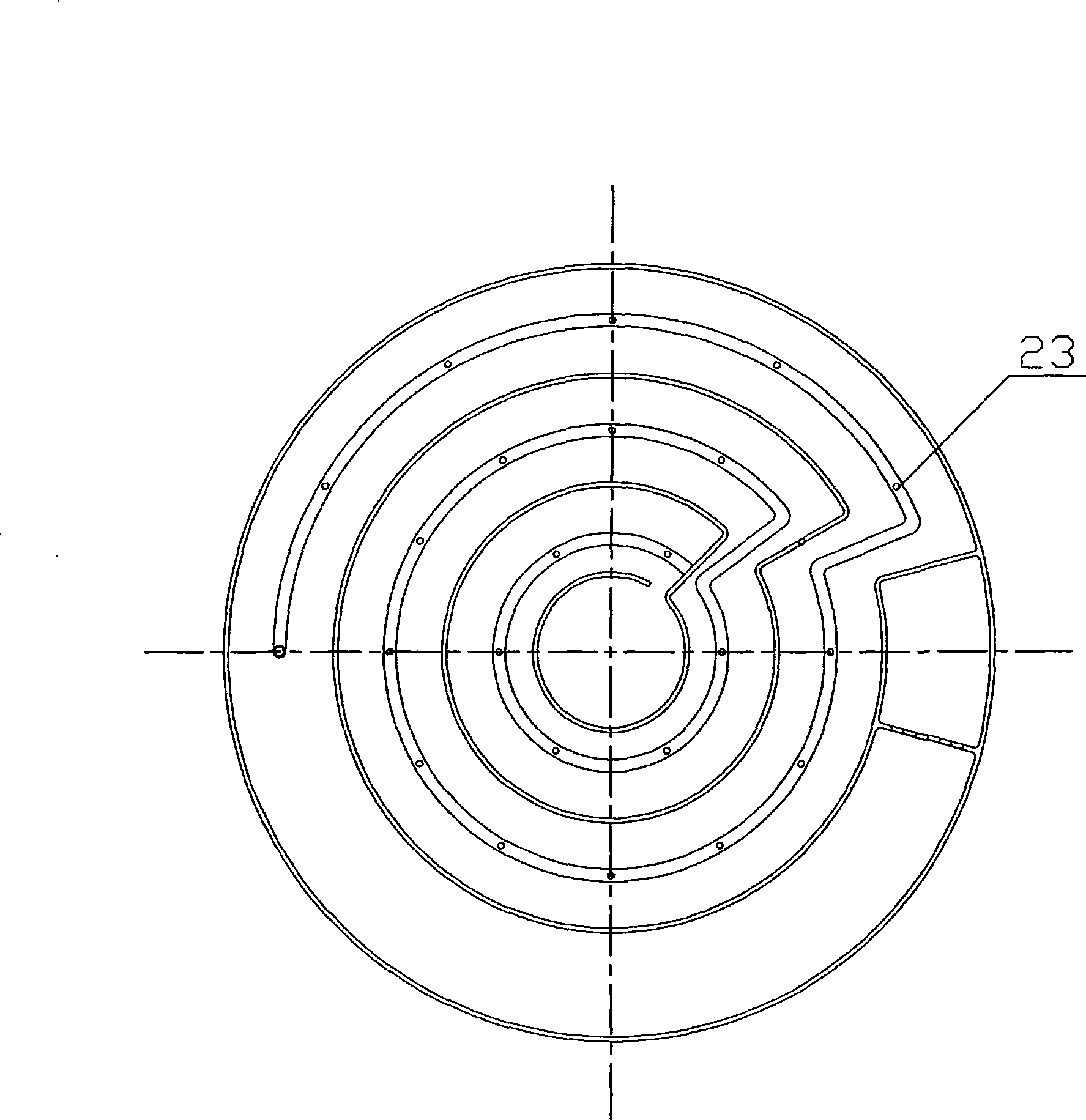

[0049] Embodiment 1, the solid sodium chlorate of 99% concentration and the hydrogen peroxide of 50% concentration are formulated as sodium chlorate mixed solution and put into sodium chlorate metering tank, the concentrated sulfuric acid of 98% concentration is diluted with water to 75% concentration Dilute sulfuric acid is loaded into the sulfuric acid metering tank; the metering pump is used to feed continuously to the Venturi mixer according to the molar ratio of sulfuric acid: sodium chlorate: hydrogen peroxide = 1.9:1.9:0.9, and the two solutions are heated to 56°C before entering the mixer. The air is heated to 56°C before entering the mixer. Sulfuric acid, sodium chlorate mixture and air are mixed into a mist gas-liquid mixture in the Venturi mixer, and then enter the gas-liquid separator for gas-liquid separation, and the separated reaction liquid enters the reactor for multi-layer cyclone aeration reaction. After testing, the purity of chlorine dioxide gas is 95%, a...

Embodiment 2

[0050] Embodiment 2, the solid sodium chlorate of 99% concentration and the hydrogen peroxide of 50% concentration are formulated as sodium chlorate mixed solution and put into sodium chlorate metering tank, the concentrated sulfuric acid of 98% concentration is diluted with water to 70% concentration Dilute sulfuric acid is loaded into the sulfuric acid metering tank; the metering pump continuously feeds the material to the Venturi mixer according to the molar ratio of sulfuric acid: sodium chlorate: hydrogen peroxide = 2:2:1, and the two solutions are heated to 60°C before entering the mixer. The air is heated to 60°C before entering the mixer. Sulfuric acid, sodium chlorate mixture and air are mixed into a mist gas-liquid mixture in the Venturi mixer, and then enter the gas-liquid separator for gas-liquid separation, and the separated reaction liquid enters the reactor for multi-layer cyclone aeration reaction. After testing, the purity of chlorine dioxide gas is 95%, and ...

Embodiment 3

[0051] Embodiment 3, the solid sodium chlorate of 99% concentration and the hydrogen peroxide of 50% concentration are prepared as sodium chlorate mixed solution and put into sodium chlorate metering tank, the concentrated sulfuric acid of 98% concentration is diluted with water to be 70% concentration Dilute sulfuric acid is loaded into the sulfuric acid metering tank; the metering pump continuously feeds the material to the Venturi mixer according to the molar ratio of sulfuric acid: sodium chlorate: hydrogen peroxide = 2.1: 2.1: 1.1, and the two solutions are heated to 64°C before entering the mixer. The air is heated to 64°C before entering the mixer. Sulfuric acid, sodium chlorate mixture and air are mixed into a mist gas-liquid mixture in the Venturi mixer, and then enter the gas-liquid separator for gas-liquid separation, and the separated reaction liquid enters the reactor for multi-layer cyclone aeration reaction. After testing, the purity of chlorine dioxide gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com