Method for manufacturing construction composite panel with sedimentary deposit

A manufacturing method and technology for composite sheets, applied in chemical instruments and methods, coating, lamination, etc., can solve the problems of environmental pollution, burden, etc., and achieve the best wear resistance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

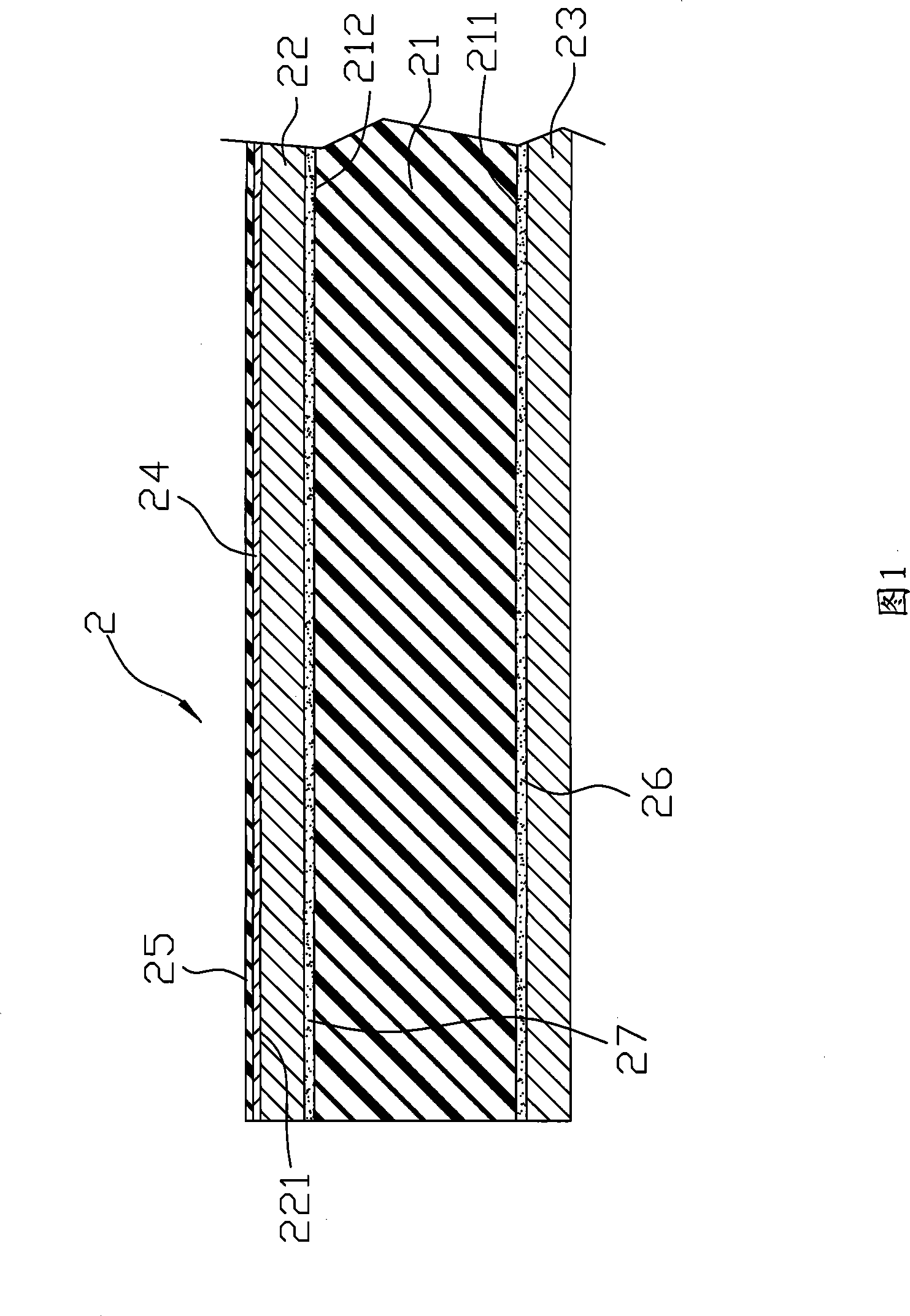

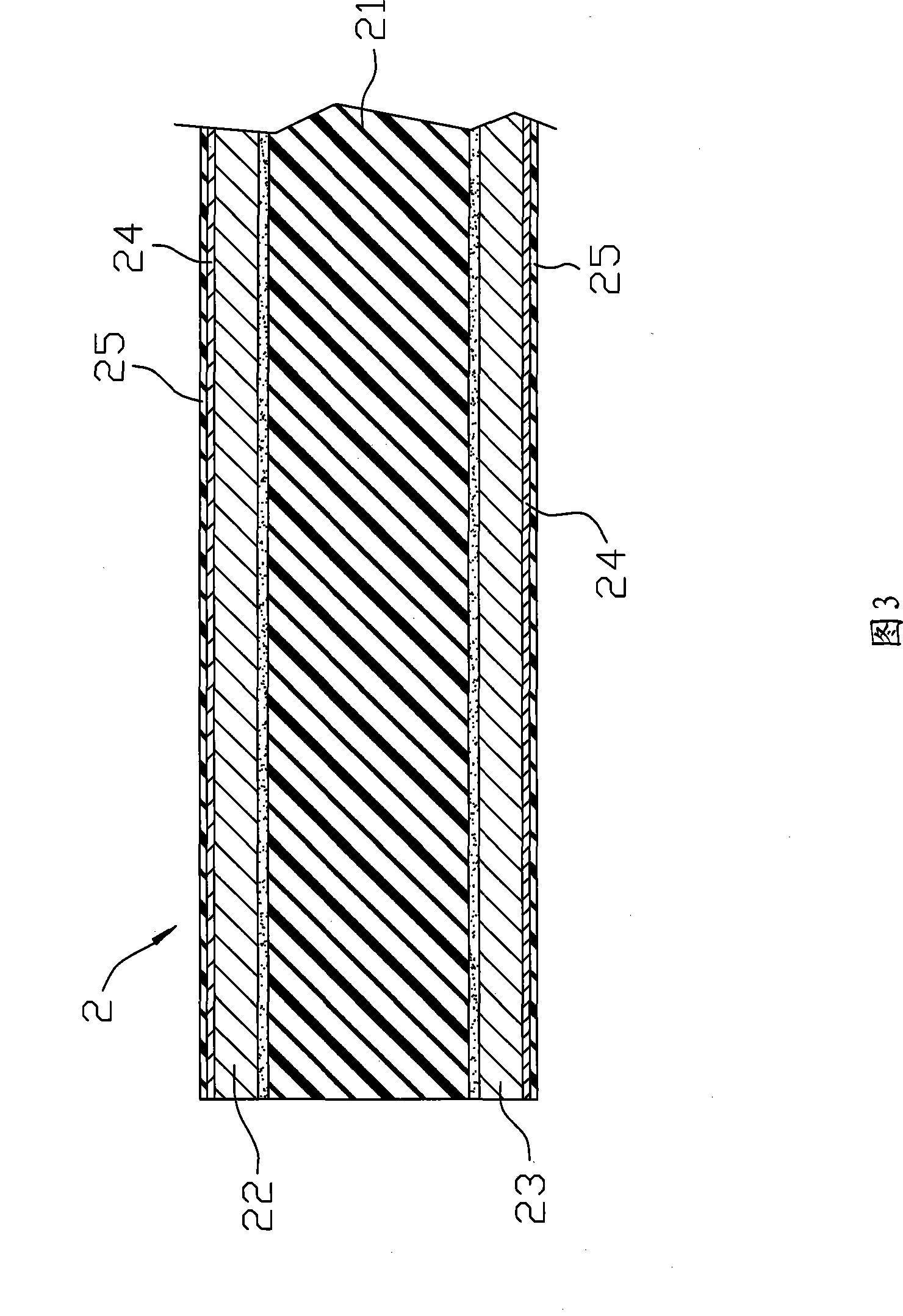

[0012] Referring to Fig. 1, the first preferred embodiment of the manufacturing method of the present invention is used to manufacture the building composite board 2 shown in Fig. 1, and the building composite board 2 comprises: a core layer 21 made of a plastic material, a roll A first substrate 22, a second substrate 23, a layer of deposition layer 24 attached to the first substrate 22, a layer of transparent substrate attached to the surface of the deposition layer 24, which are cylindrical and located on the opposite side of the core layer 21. The paint layer 25 , and the adhesive layers 26 , 27 fixedly bond the first substrate 22 and the second substrate 23 to the two surfaces 211 , 212 of the core layer 21 .

[0013] The core layer 21 of the present invention can be selected for example: polyethylene (Polyethylene, referred to as PE), polypropylene (Polypr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com