Electric-controlled natural gas engine operating system and control method thereof

A technology of working system and control method, applied in the direction of engine control, electrical control, engine components, etc., can solve the problem of large difference in ignition point and combustion speed between gasoline and natural gas, emission, power, efficiency, and inaccurate control of natural gas intake etc. to achieve good control function integration performance, low cost, and good system portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are only used as examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

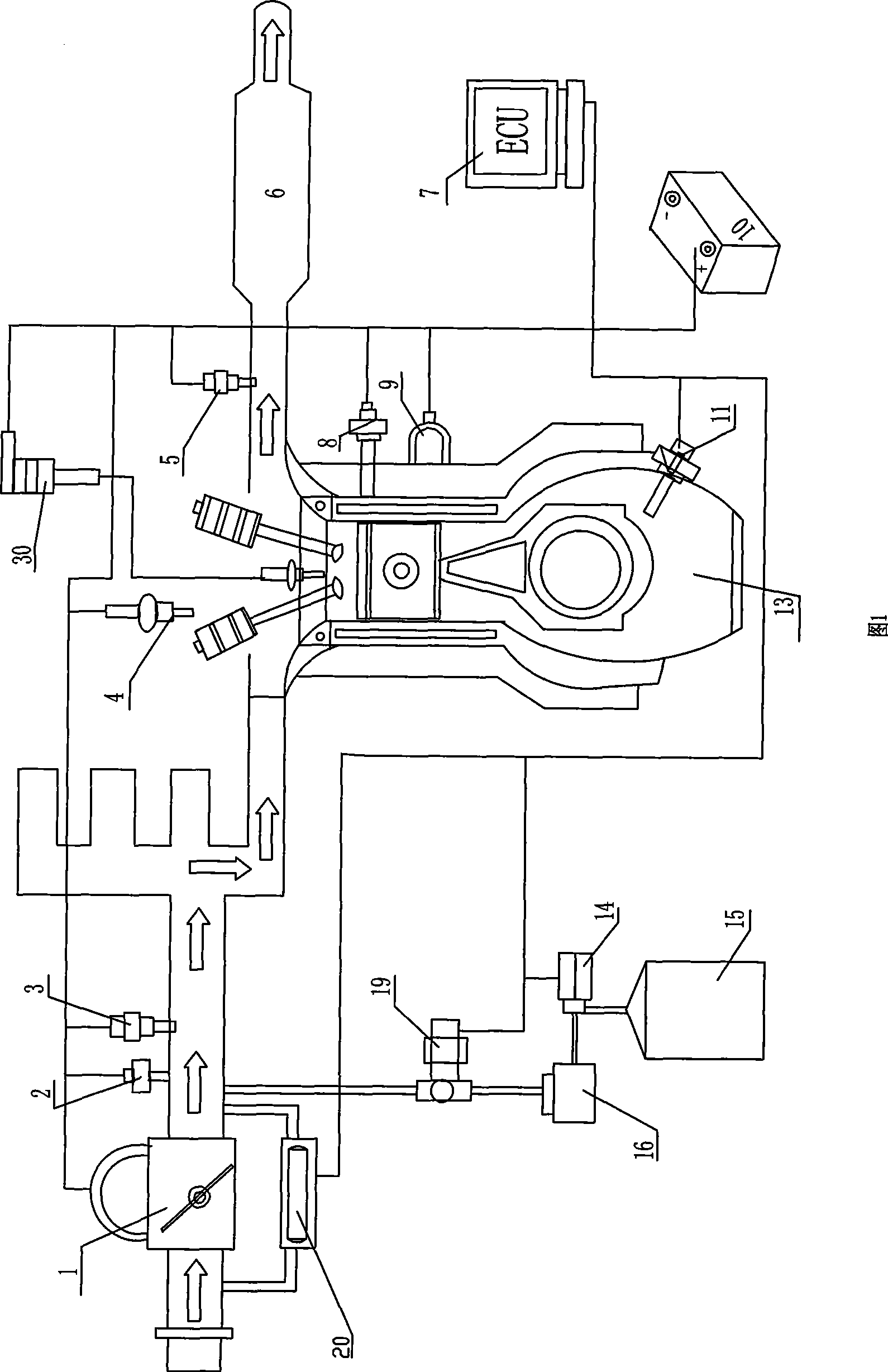

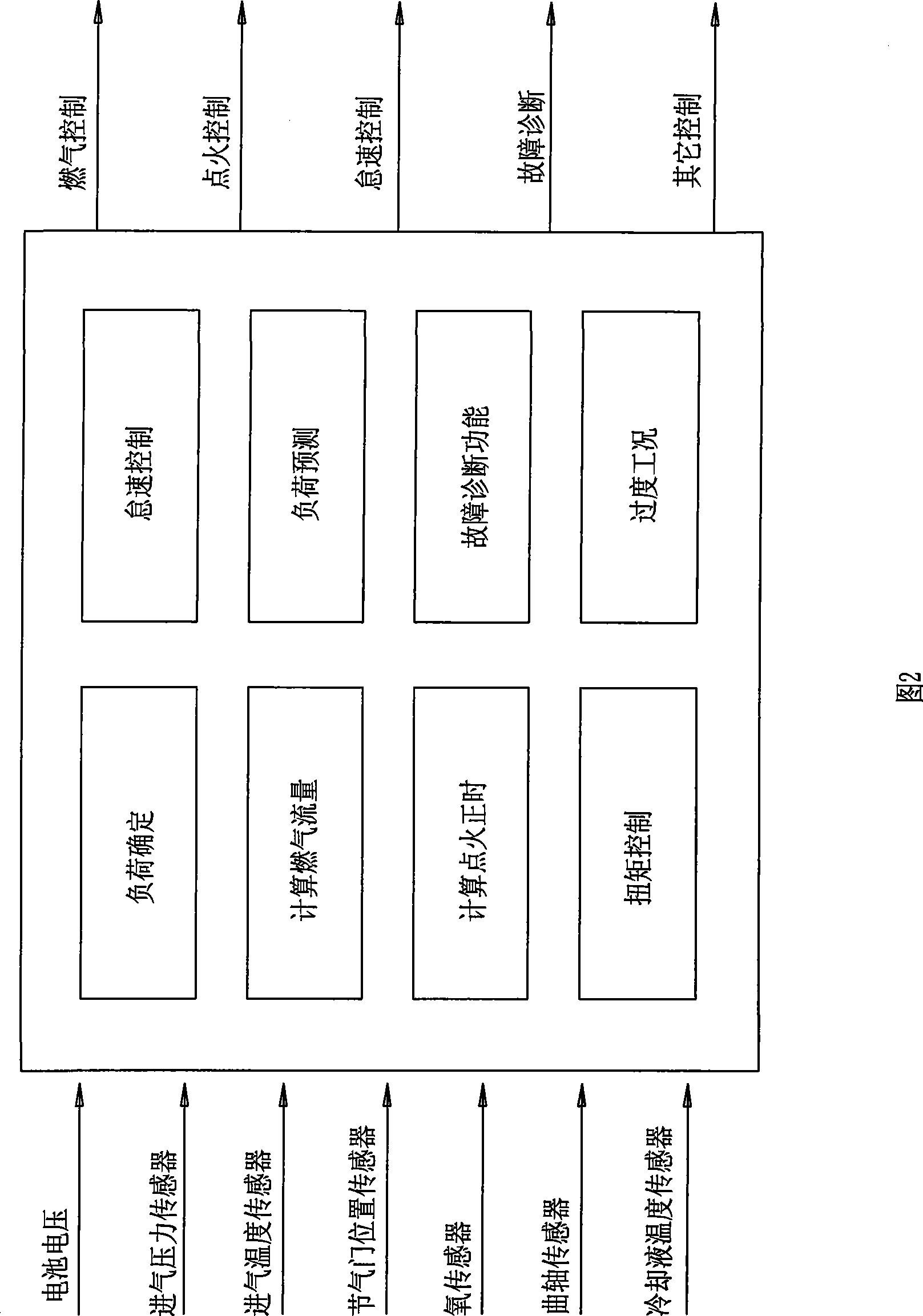

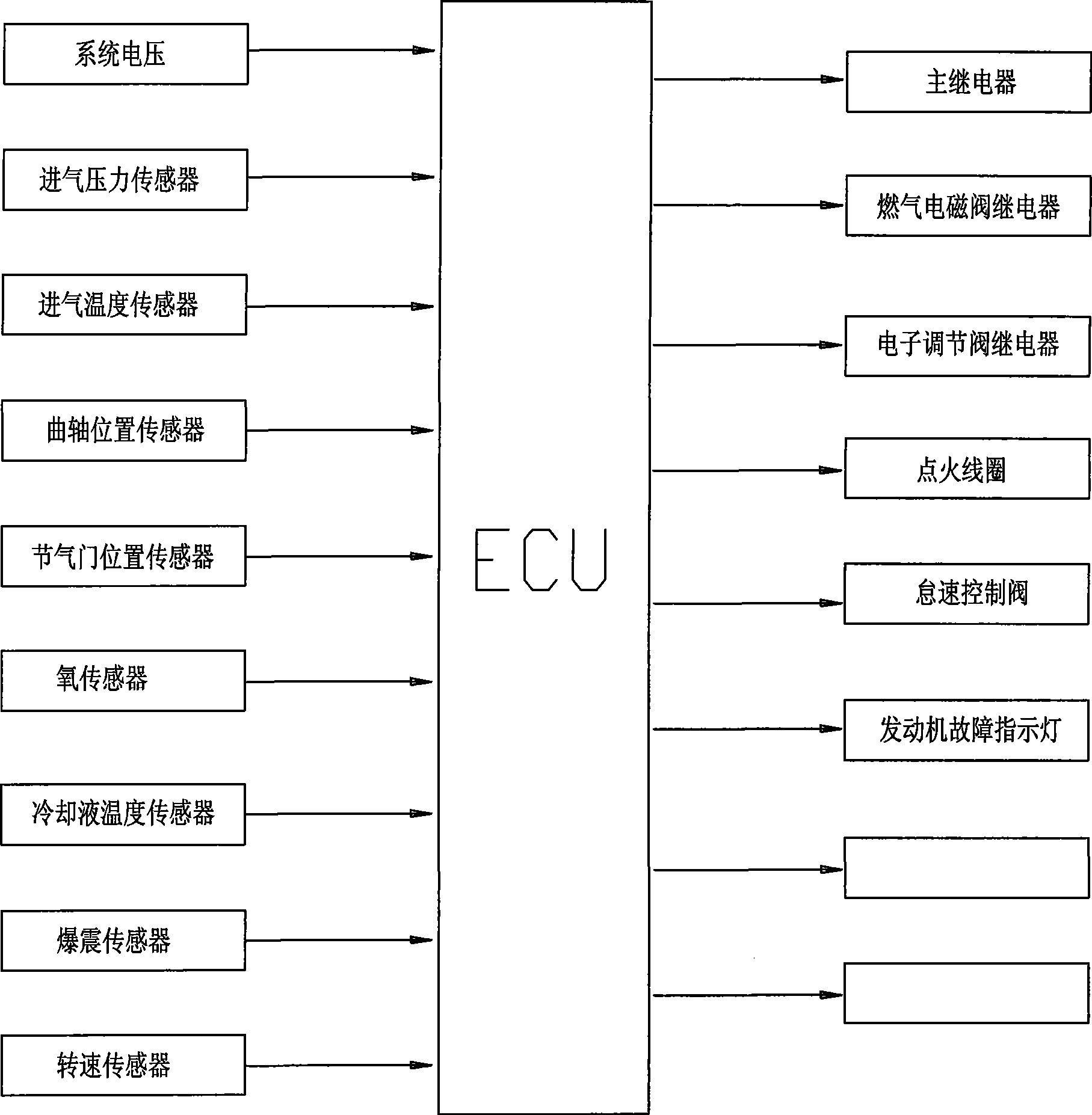

[0030] Figure 1- Figure 6 As shown, the electronically controlled natural gas engine working system of the present invention takes the electronic control unit ECU as the core, and the ECU hardware selects a high-performance 16-bit microcontroller (MCU), which has a wide operating temperature range, high computing speed, Large program and data memory, flexible I / O ports, etc. The ECU drive circuit uses a drive IC with diagnostic function, which can realize the open circuit and short circuit detection of the drive output circuit; the software is compiled in modular C language, and uses FLASH self-programming technology, which can realize the modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com