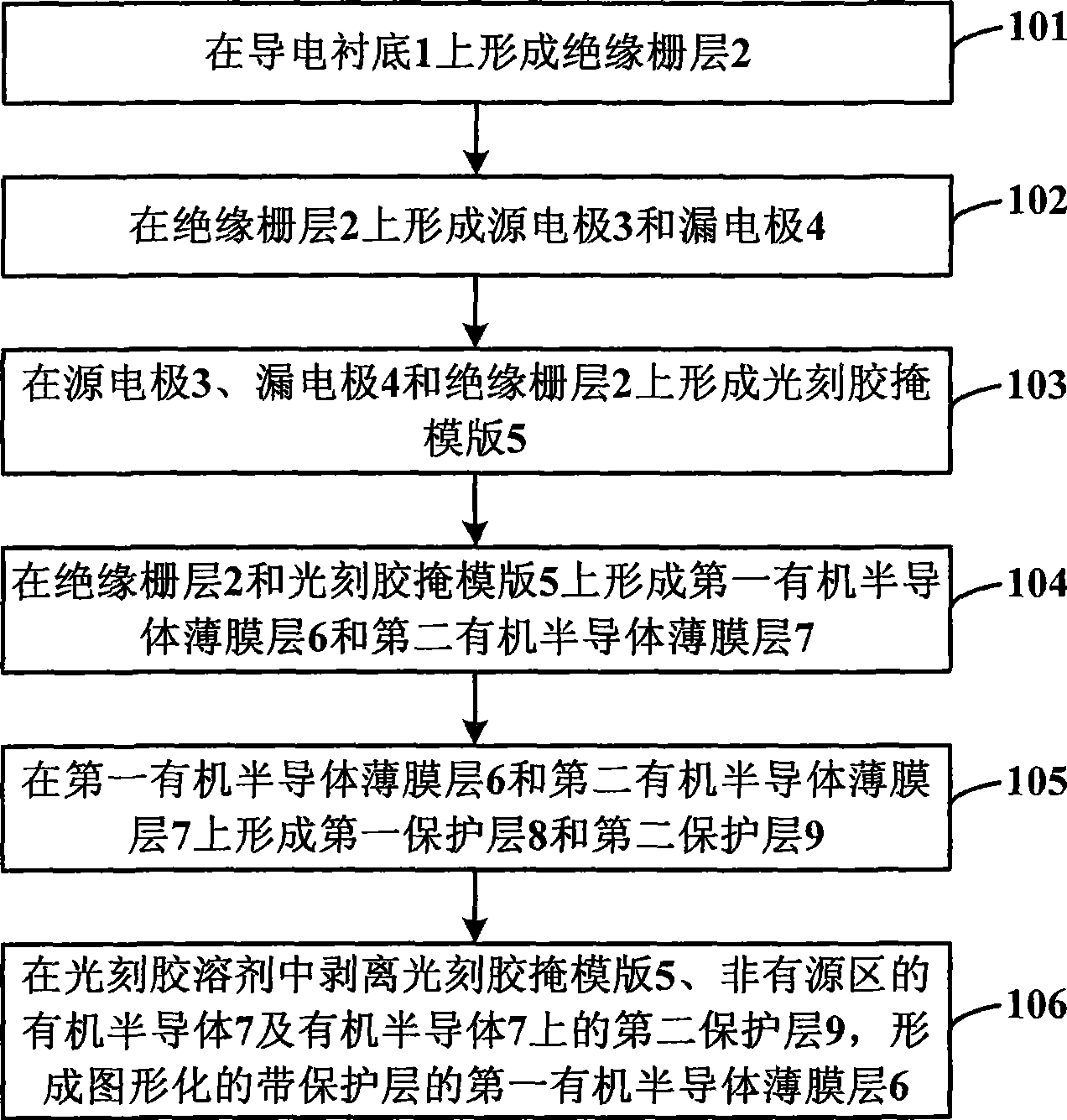

Production method for organic thin-film transistor with graphic active layer

An organic thin-film, patterning technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as performance degradation, organic thin-film performance damage, and manufacturing process limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

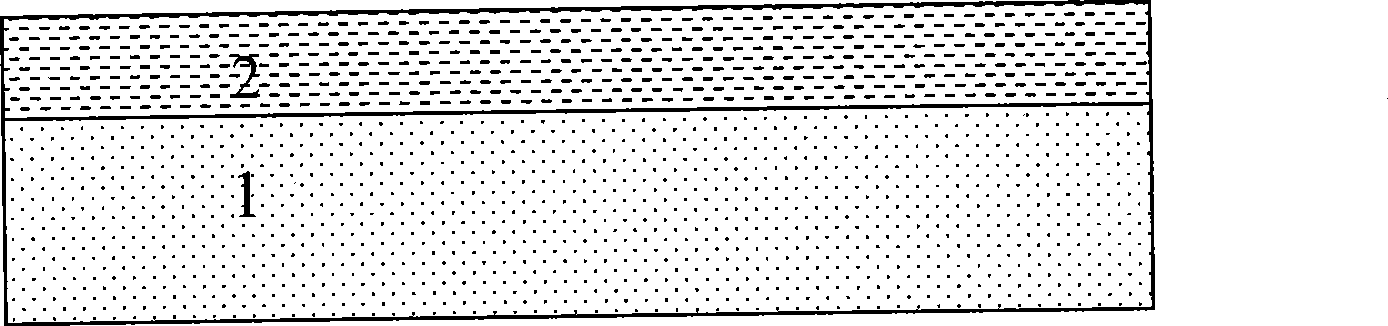

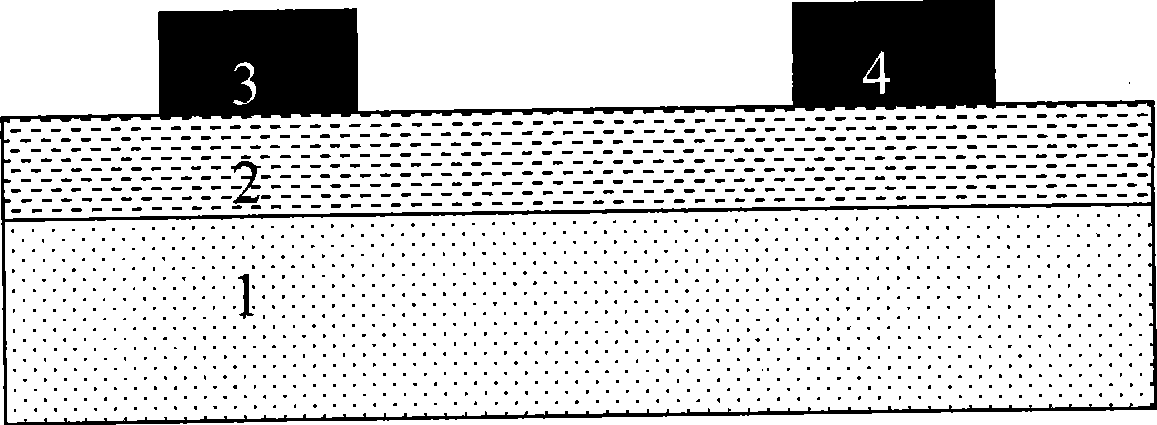

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0035] The core content of the present invention is: after the preparation of the metal source and drain electrodes, the photoresist is used as a mask, and the organic semiconductor thin film layer is prepared by vacuum evaporation method, and then a layer of organic semiconductor thin film layer is prepared by room temperature PECVD method on the organic semiconductor thin film layer. protective layer, and make the sum of the organic semiconductor thin film layer and the protective layer thickness less than the thickness of the metal source drain electrode, to ensure that the glue remover does not contact the organic semiconductor thin film layer when removing the photoresist mask, causing the Destruction of the propertie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com