Infrared-ultraviolet multi-color detector and production process thereof

A detector and ultraviolet technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as unfavorable system integration, complex packaging, high cost, etc., to enhance recognition ability, reduce false alarm rate, cost high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

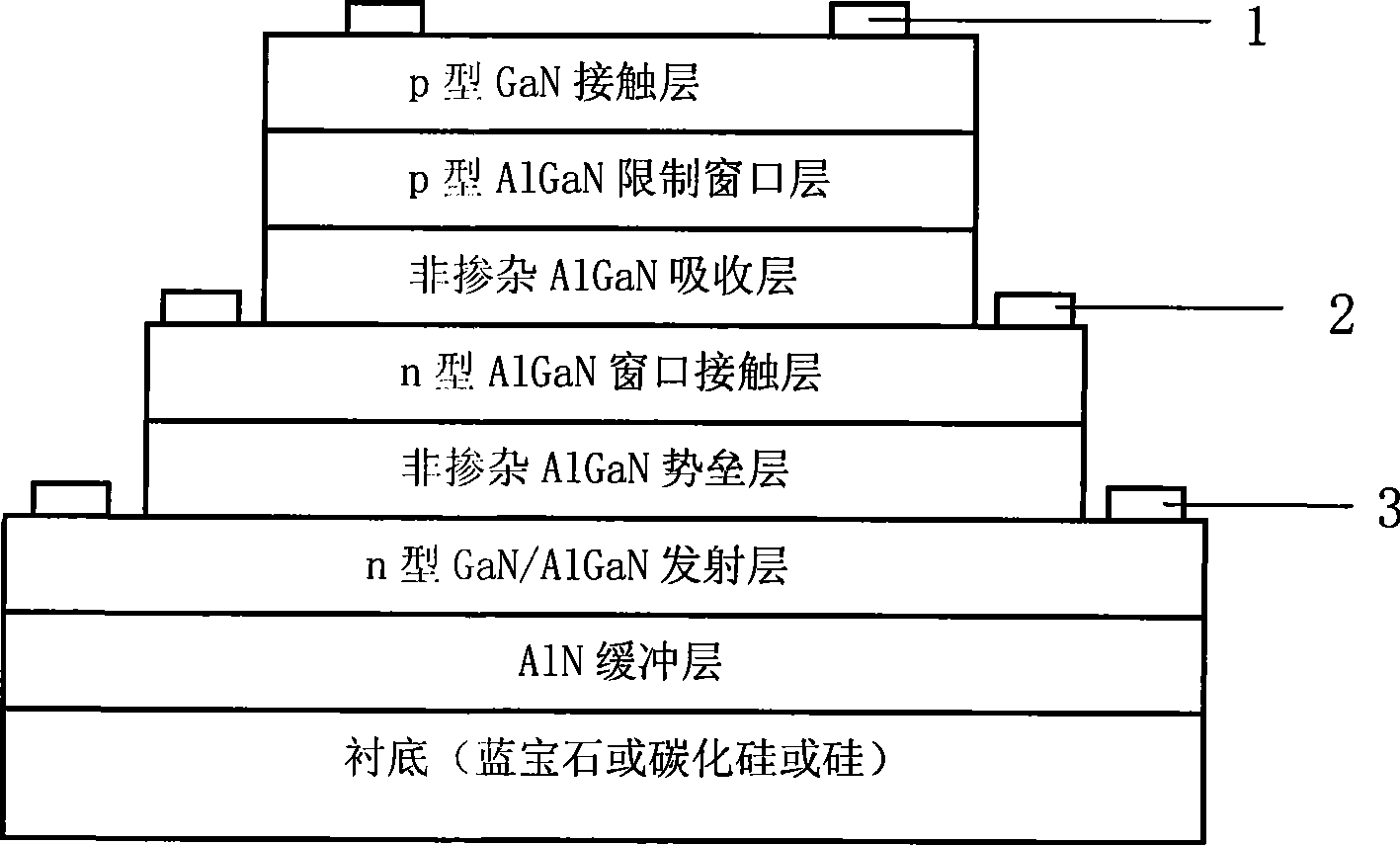

[0019] Such as figure 1 As shown, the infrared-ultraviolet multicolor detector grows AlN buffer layer, n-type GaN / AlGaN emission layer, non-doped AlGaN barrier layer, n-type AlGaN window contact layer, non-doped AlGaN absorption layer on the substrate sequentially. Layer, p-type AlGaN confining window layer and p-type GaN contact layer form a two-level convex multi-color detector mesa, with n-type GaN / AlGaN emitter layer and n-type AlGaN window contact layer as protrusions. There is an n-type lower contact electrode 3 on the boss of the n-type GaN / AlGaN emitter layer, an n-type middle contact electrode 2 on the boss of the n-type AlGaN window contact layer, and a p-type upper contact electrode on the p-type GaN contact layer. Contact electrode 1.

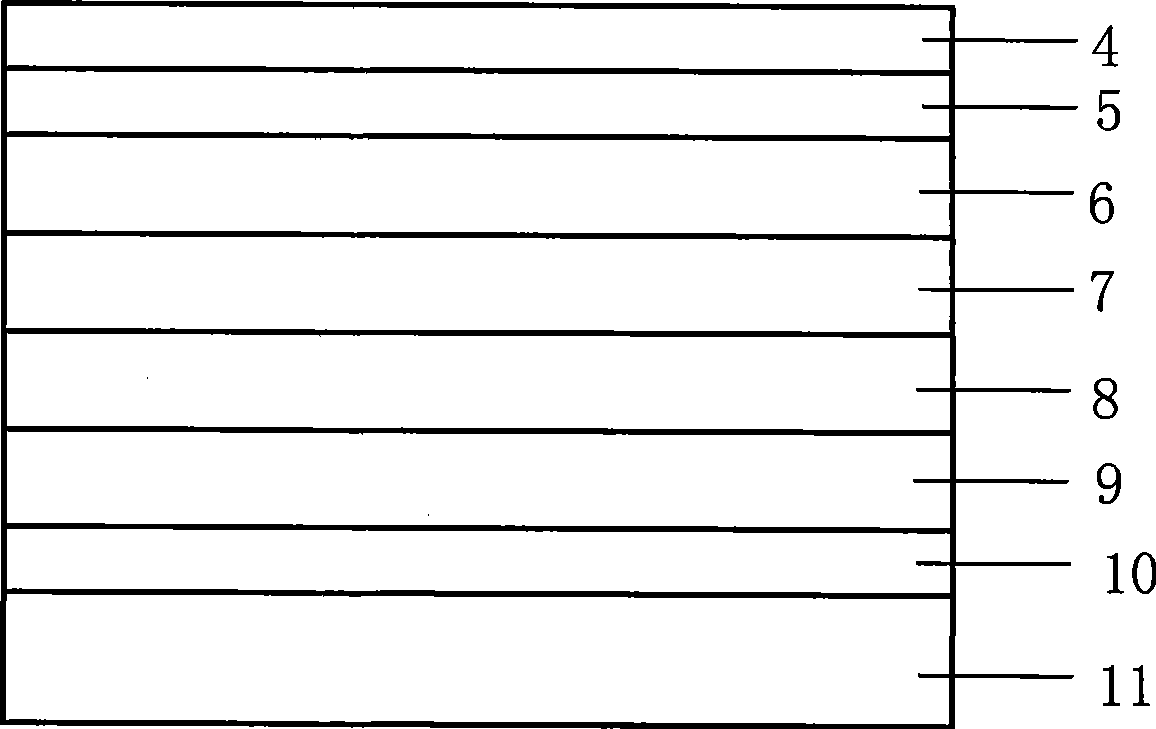

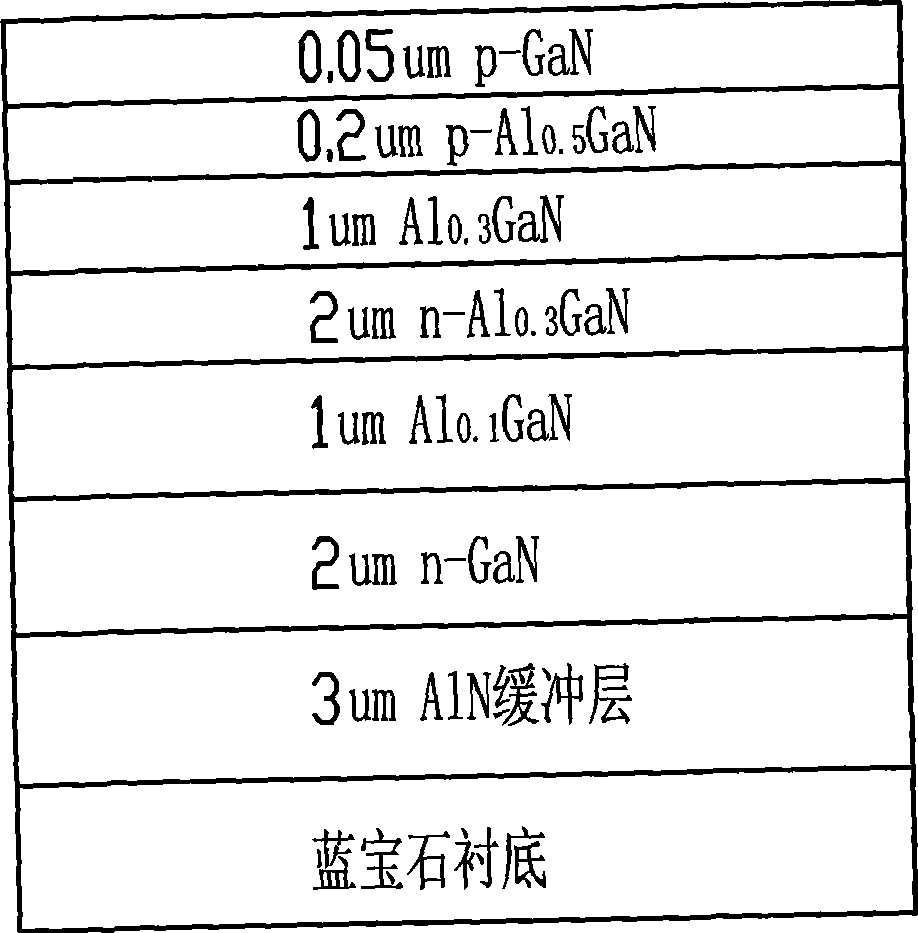

[0020] The substrate described in this infrared-ultraviolet multicolor detector is preferably Si, sapphire or silicon carbide polished substrate, in order to achieve better infrared / ultraviolet detection effect, such as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com