Remixing process of dry pulverized coke and wet pulverized coke of coke making raw material

A technology of dry coke powder and coke powder, which is applied in the field of recycling dry coke powder and wet coke powder to achieve the effects of preventing damage, saving energy and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

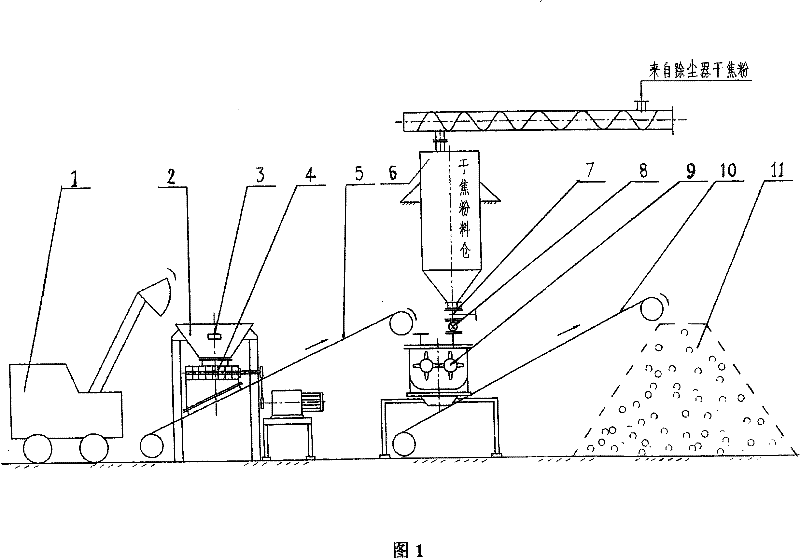

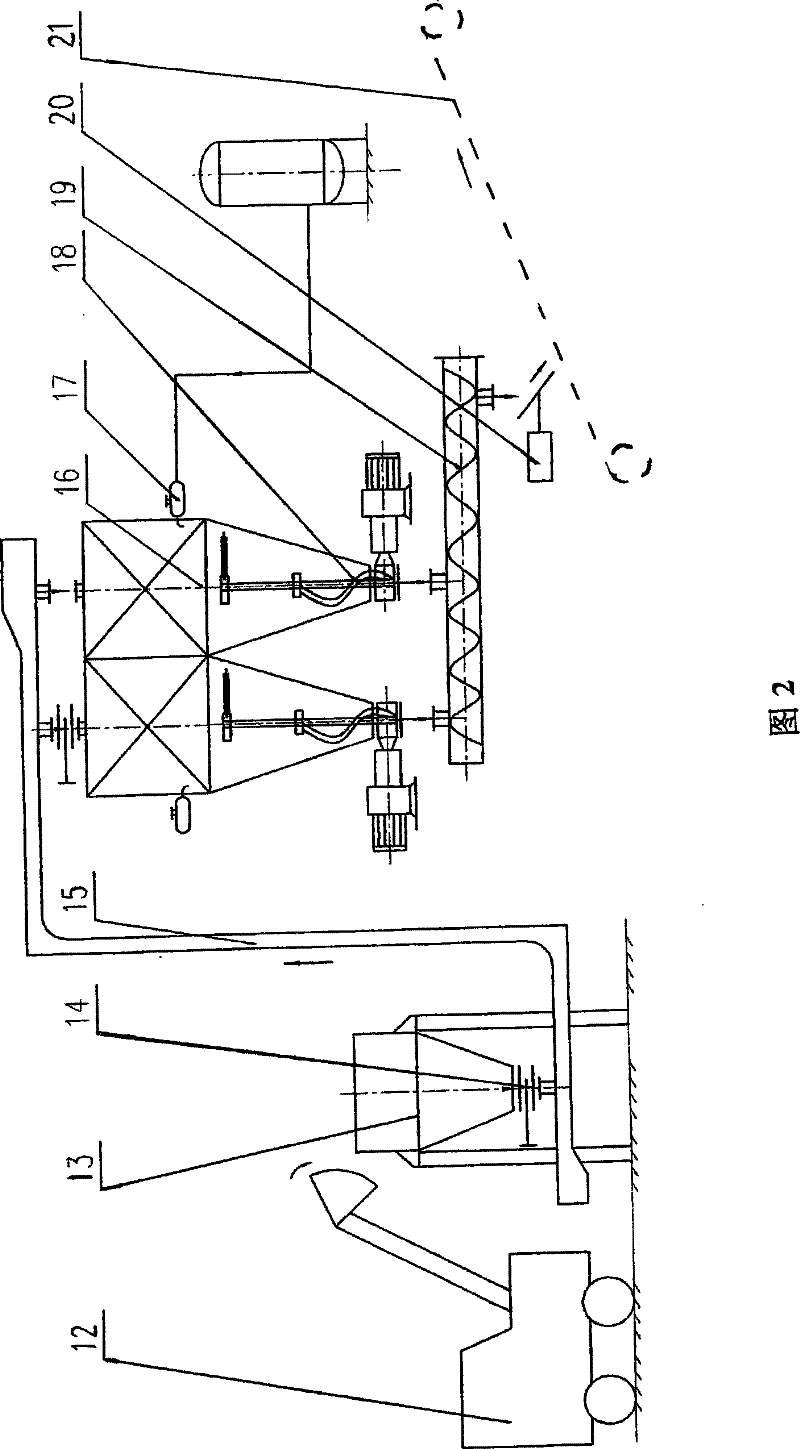

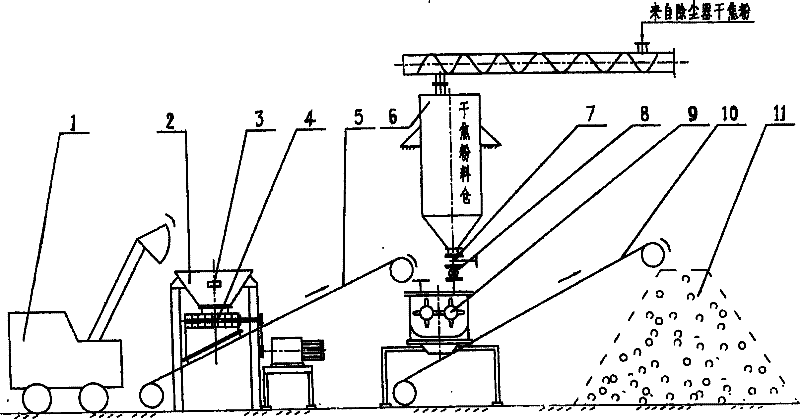

[0028] The remixing process of dry coke powder and wet coke powder of coking waste includes the mixing process of dry coke powder and wet coke powder and the addition process of coke powder, (1) the mixing process of dry coke powder and wet coke powder: [6] enters the dry and wet material mixer [9] through the gate valve [7] and the speed-regulating rotary valve [8] in proportion; the wet coke powder with a moisture content of 41.7% by weight is transported by the loader [1] to the Hopper [2] via 1 * The No. belt conveyor [5] transports into the wet material mixer [9] in proportion, and the dry and wet coke powders are evenly mixed. Obtain the coke powder mixture with moisture content≤10% by weight, through 2 * No. belt conveyor [10] is transported to the temporary storage yard. (2) Coke powder addition process: the coke powder mixture is transported to the intermediate silo [16] through the loader [12], and the coke powder mixture in the intermediate silo [16] is pushed bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com