Method for preparing metal liquid mixed with granule having high heat-transfer performance

A metal liquid, high heat transfer technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low thermal conductivity, increased demand for heat dissipation of chips, etc., and achieve good performance, wide application range, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

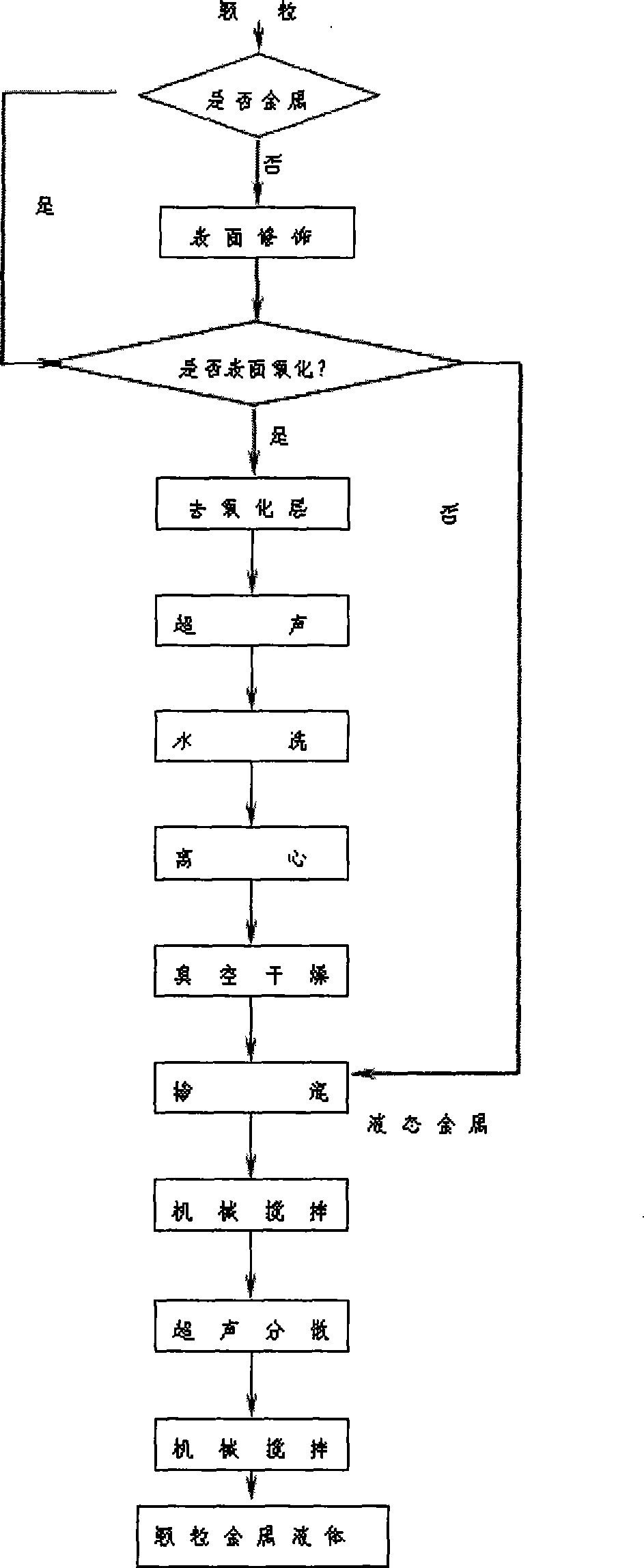

Method used

Image

Examples

Embodiment 1

[0032] 100 mg of single-walled carbon nanotubes, the particle diameter of which is 900 nanometers, is added to 20 ml of mixed acid (volume ratio of 3) of sulfuric acid and nitric acid, and then soaked in 0.1mol / L NaOH solution at 80°C for 10 Minutes, after ultrasonic washing with deionized water, and then with 0.2mol / LNiSO 4 Soak at room temperature for 10 minutes, wash with water, and then use KBH 4 Reduction of Ni adsorbed on nanotubes 2+ , at 0.0024M / LPdCl 2 Activated in the activation solution. The activated nanotubes were thoroughly rinsed with deionized water until the pH was equal to 7, and then added to the pre-prepared solution containing NiSO 4 , NaH 2 PO 4 , Na 3 C 6 h 5 o 7 , NaAc plating solution for electroless nickel plating. The electroless-plated nanoparticles were sonicated for 15 minutes, washed with deionized water until neutral, centrifuged, and vacuum-dried to obtain carbon nanotubes with metal surfaces.

[0033] Blend the surface-modified carb...

Embodiment 2

[0035] According to the preparation method of Example 1, only the liquid metal gallium is replaced by mercury, and the temperature of stirring and ultrasonic dispersion is replaced by room temperature.

Embodiment 3

[0037] According to the preparation method of Example 1, only the liquid metal gallium is replaced by a gallium-indium series alloy (such as 62.5% Ga, 21.5% In, 16% Sn), and the temperature of stirring and ultrasonic dispersion is replaced by room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com