Nano meso-porous titanium dioxide coating having high efficiency antibacterial and air purification function

A nano-mesoporous, titanium dioxide technology, applied in the field of coatings, can solve the problems of limiting the efficiency of organic volatile substances, weak adsorption, etc., and achieve the effect of significant degradation effect, strong elimination effect, and purification of a wide range of pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

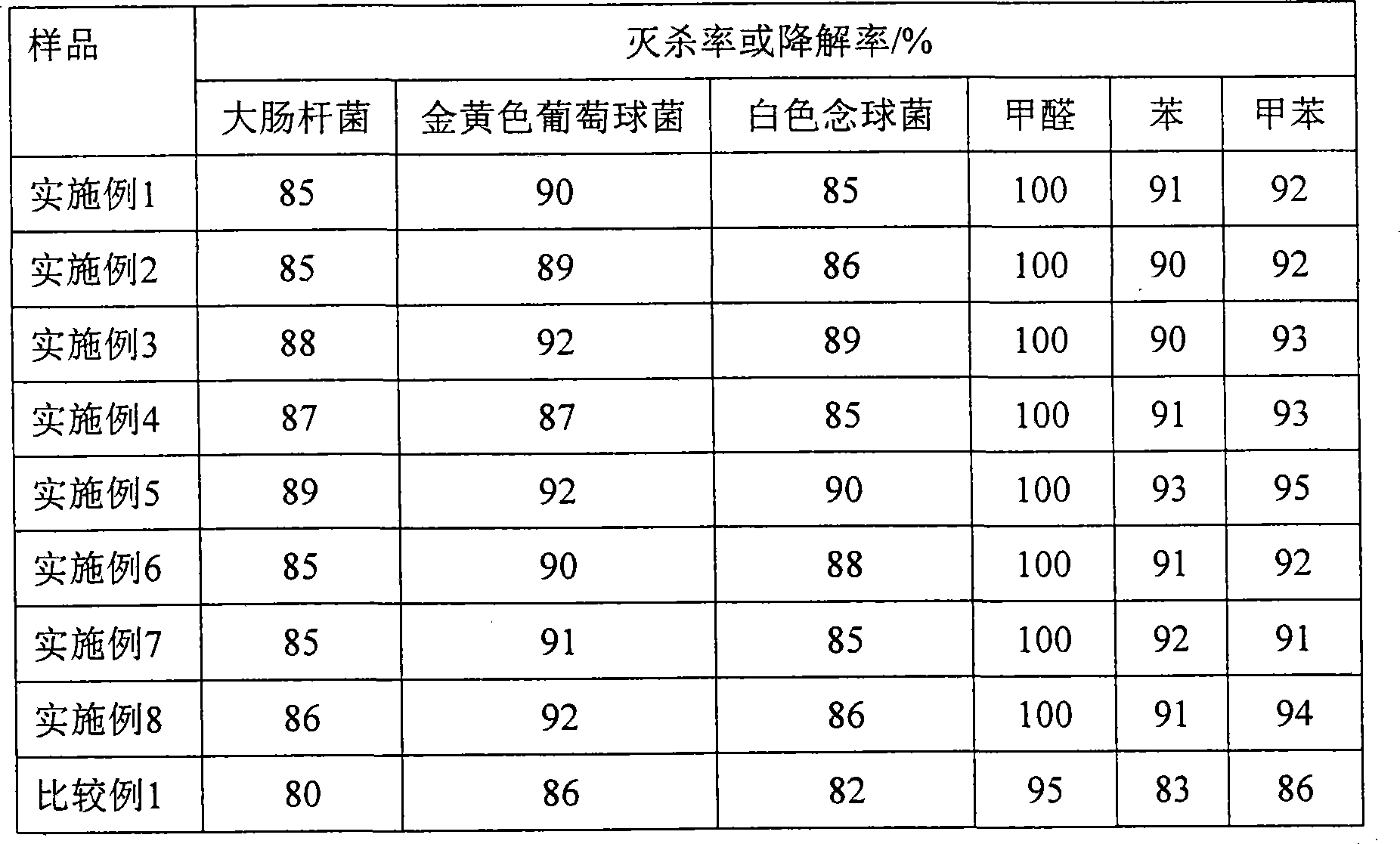

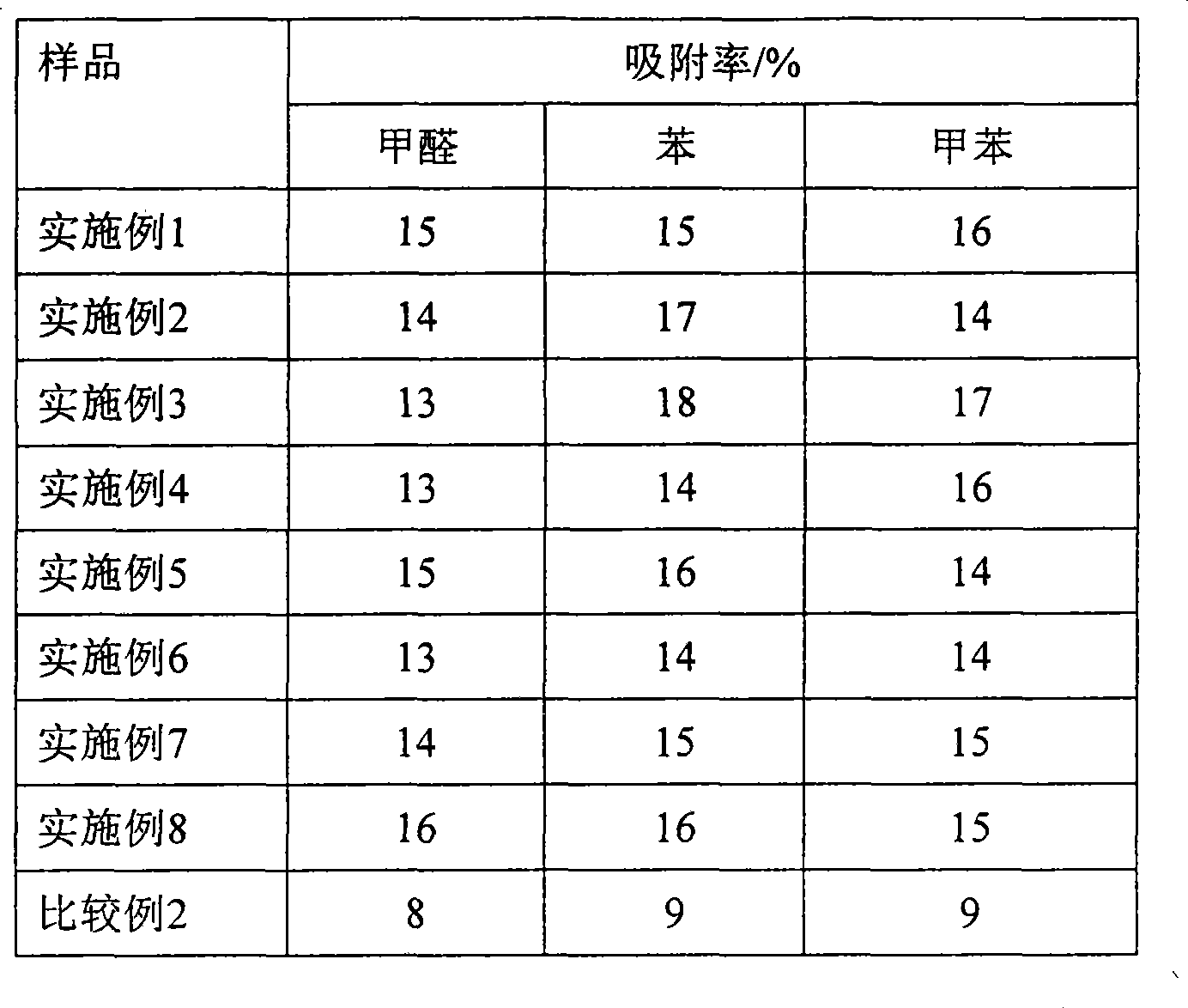

Examples

Embodiment 1

[0037] React sodium titanate in a humid atmosphere with a temperature of 100°C and a humidity of 50% for 1 hour, then wash with water, and finally air roast to obtain a particle size of 1 μm and a specific surface area of 100m 2 / g, granular nano-mesoporous titanium dioxide with a mesoporous diameter of 5 nm. Proportionally take nanometer mesoporous titanium dioxide and inorganic pigment and filler titanium dioxide and put them into a high-speed disperser to disperse for 50 minutes at a speed of 1500rpm, take them out and add them to a mixer, and slowly add ethylene glycol, acrylic resin and sodium polyacrylate at a stirring speed of 300rpm , benzyl alcohol, emulsified silicone oil, hydroxyethyl cellulose, and diphenylpolysiloxane, and continue to stir for 80 minutes to obtain the novel nanometer mesoporous titanium dioxide coating with high-efficiency antibacterial and air-purifying functions of the present invention.

[0038] The content of each component in the coating is...

Embodiment 2

[0040] Sodium titanate was reacted in a humid atmosphere with a temperature of 100°C and a humidity of 95% for 5 hours, washed with water, and finally air-calcined to obtain a particle size of 5 μm, a pore size of 15 nm, and a specific surface area of 80 m 2 / g of whisker-like nano-mesoporous titanium dioxide. Immerse 1g of nano-mesoporous titanium dioxide in 5ml of 0.1mol / l ferric nitrate solution for 5h, then add 20ml of 0.1mol / l NaOH aqueous solution for immersion for 1h to convert metal ions into metal hydroxide, filter and roast at 300°C for 2h Nanoscale mesoporous titania doped with transition metal ions Fe was obtained.

[0041] Put the nanometer mesoporous titanium dioxide doped with transition metal ion Fe and the talc powder of inorganic pigment and filler into a high-speed disperser and disperse at a speed of 2000rpm for 80 minutes, take it out and add it to the mixer, and slowly add the solvent ethyl acetate Ester, epoxy resin, sodium oleate, lauryl alcohol este...

Embodiment 3

[0044] The preparation process of the coating is as described in Example 1. The content of each component is: Pt-loaded nano-mesoporous titanium dioxide 10% (particle size 6μm, pore size 6nm, specific surface area 90m 2 / g), acetone 40%, acrylic resin 31.3%, octadecylamine acetate 0.1%, glycol butyl ether 1%, emulsified silicone oil 0.6%, hydroxyethyl cellulose 1%, diphenyl polysiloxane Alkanes 4%, silica 12%.

[0045] The preparation method of Pt loaded nanometer mesoporous titanium dioxide is: the sodium hydroxide ethylene glycol solution of 10ml 0.1mol / l is added dropwise in the ethylene glycol solution of the 0.01mol / l chloroplatinic acid of 5ml vigorous stirring, nitrogen gas Heating to 160°C under protection, constant temperature for 3 hours, after cooling, add 2 g of nano-mesoporous titanium dioxide prepared by the method in Example 2 and stir for 4 hours, add hydrochloric acid in ethylene glycol solution, adjust the pH value to between 2 and 4, and stir for 5 hours A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com