Method for preparing poly-aspartic potassium used in plant growth accelerator and use

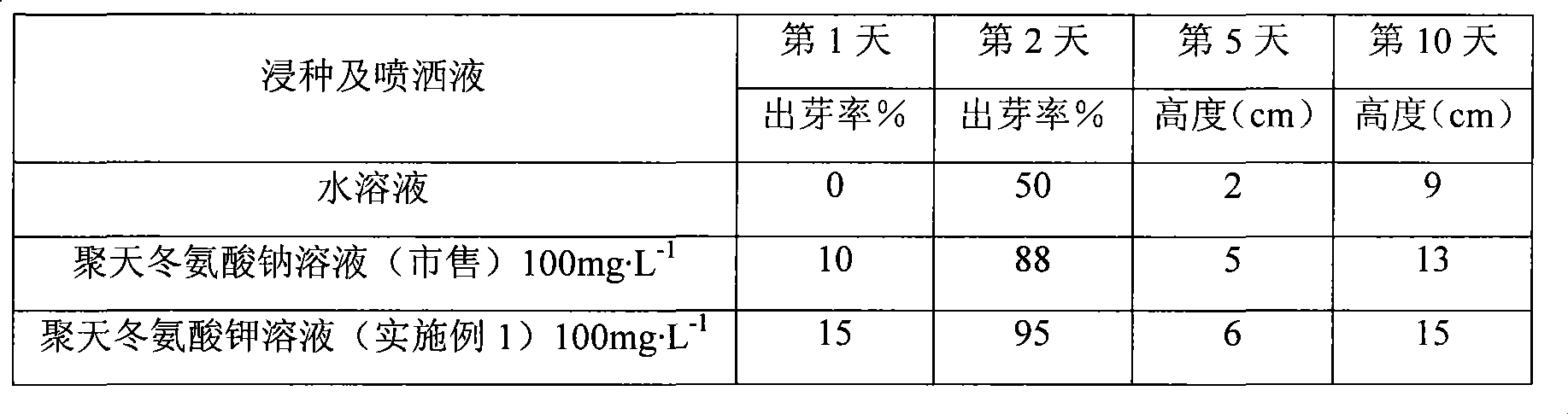

A technology for potassium polyaspartate and plant growth promotion, applied in the direction of organic fertilizers, etc., can solve the problems of lowering the polymerization reaction temperature, shortening the reaction time, and high polymerization temperature, and achieves increased yield, balanced plant nutrients, and low reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

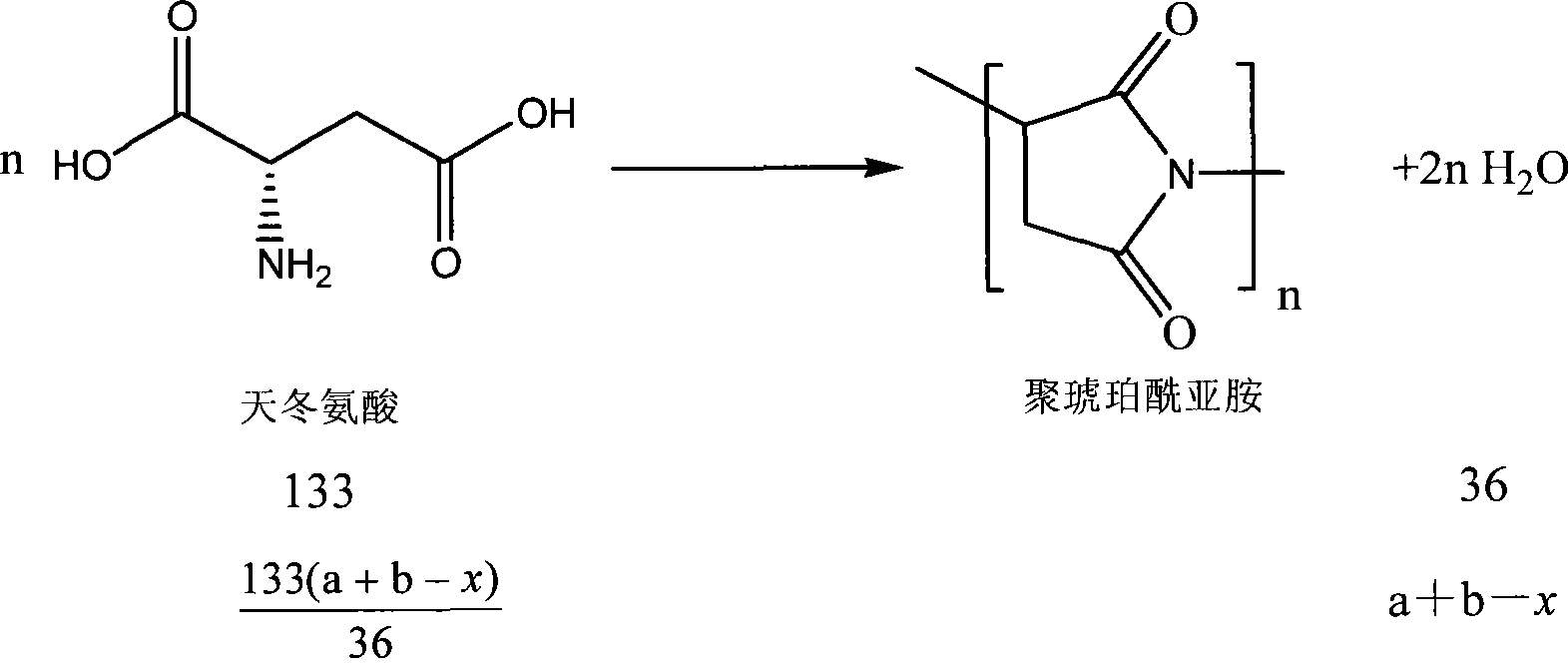

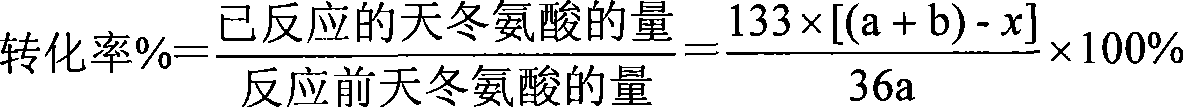

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of potassium polyaspartate

[0030] 133.00 g of aspartic acid (1 mol), 1.24 g of boric acid (0.02 mol) and 5.22 g of potassium sulfate (0.03 mol) were added to 139.46 g of water, dissolved and then removed in a rotary evaporator. The dried mixture was put into a four-necked flask and heated to about 190° C. in an oil bath. After 8.0 hours, 104.11 g of light yellow polysuccinimide was obtained. According to the weight loss method, the conversion rate was 98.19%. Add 133.00 g of water to the obtained polysuccinimide and heat it to 70° C., and slowly add 224 g of 25% potassium hydroxide aqueous solution at this temperature for hydrolysis to obtain a yellow viscous liquid with a solid content of not less than 35%. Potassium polyaspartate solution, molecular weight test 8,750.

Embodiment 2

[0031] Embodiment 2: the preparation of potassium polyaspartate

[0032] 133.00 g of aspartic acid (1 mol), 3.1 g of boric acid (0.05 mol) and 8.70 g of potassium sulfate (0.05 mol) were added to 144.80 g of water, and then the water was removed in a rotary evaporator. The dried mixture was put into a four-necked flask and heated to about 180° C. in an oil bath. After 4.5 hours, 109.02 g of light yellow polysuccinimide was obtained. According to the weight loss method, the conversion rate was 99.4%. Add 133g of water to the obtained polysuccinimide and heat it to 70°C, and slowly add 224g of 25% potassium hydroxide aqueous solution at this temperature for hydrolysis to obtain a yellow viscous liquid with a solid content of not less than 35%. Potassium Aspartate Solution, Molecular Weight Tested 8,600.

Embodiment 3

[0033] Embodiment 3: the preparation of potassium polyaspartate

[0034] 133.0 g of aspartic acid (1 mol), 3.1 g of boric acid (0.05 mol) and 8.7 g of potassium sulfate (0.05 mol) were added to 144.8 g of water, and then the water was removed in a rotary evaporator. The dried mixture was put into a four-necked flask and heated to about 180° C. in an oil bath. After 4.5 hours, 109.0 g of light yellow polysuccinimide was obtained. According to the weight loss method, the conversion rate was 98.4%. Add 133g of water to the obtained polysuccinimide and heat it to 70°C, and slowly add 224g of 25% potassium hydroxide aqueous solution at this temperature for hydrolysis to obtain a yellow viscous liquid with a solid content of not less than 35%. Potassium Aspartate Solution, Molecular Weight Tested 8,600.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com