Upper part of an assembled piston

A technology of parts and pistons, which is applied in the field of upper parts of assembled pistons, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

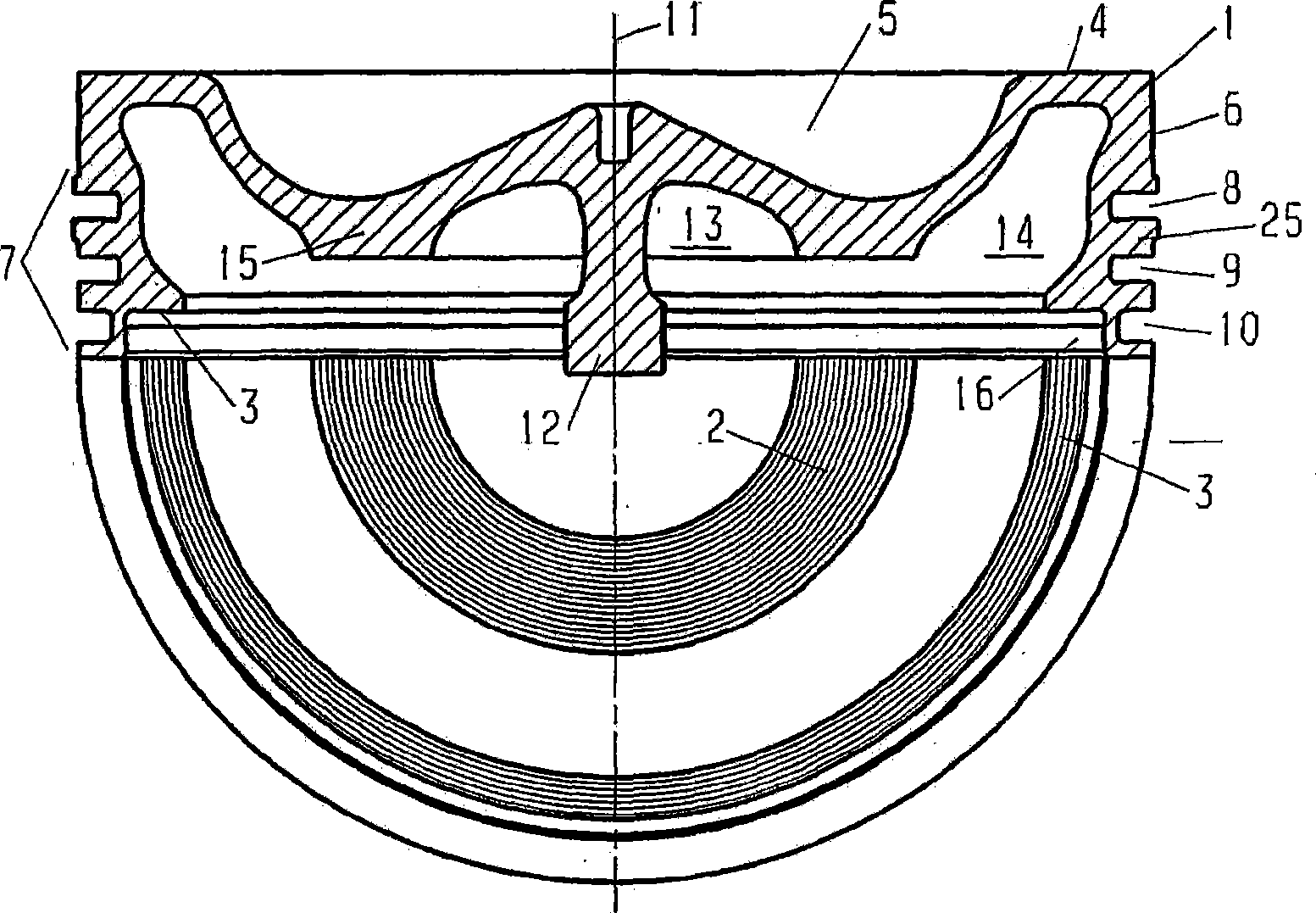

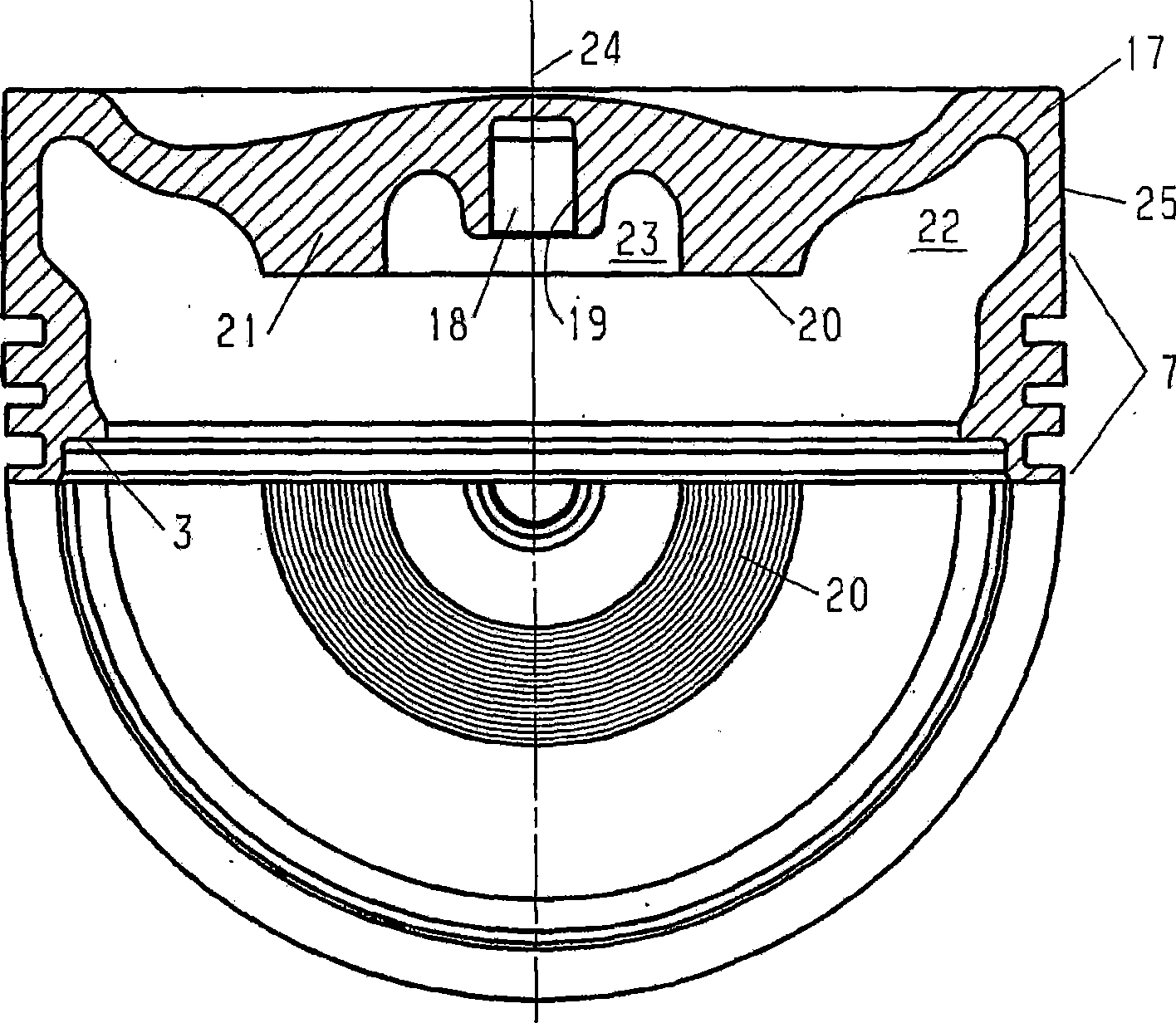

[0008] figure 1 The upper part 1 of the piston is shown, the lower part of which is not shown in the schematic diagram, in figure 1 A bottom side view of half of the upper part 1 is briefly shown in , which shows the inner radial contact surface 2 and the outer radial contact surface 3 , wherein the upper part bears against the piston 1 via the contact surfaces 2 and 3 on the lower part. The upper part 1 is produced from steel. The lower part can be made of steel, aluminum or cast iron with nodular graphite.

[0009] The upper part 1 has a piston crown pocket 5 formed in its piston crown 4 . The radially outer region of the upper part 1 on the piston top side is designed as a refractory blunt 6 to which a piston ring 7 with three annular grooves 8 , 9 , 10 is connected in the direction away from the piston top.

[0010] The underside of the upper part 1 facing away from the piston crown has a screw 12 coaxial to the piston axis 11 , by means of which the upper part 1 is sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com