Compensation container for cooling systems of internal combustion engines

A technology of cooling system, internal combustion engine, applied in the direction of engine cooling, machine/engine, mechanical equipment, etc., can solve problems such as uncontrollable, functional damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

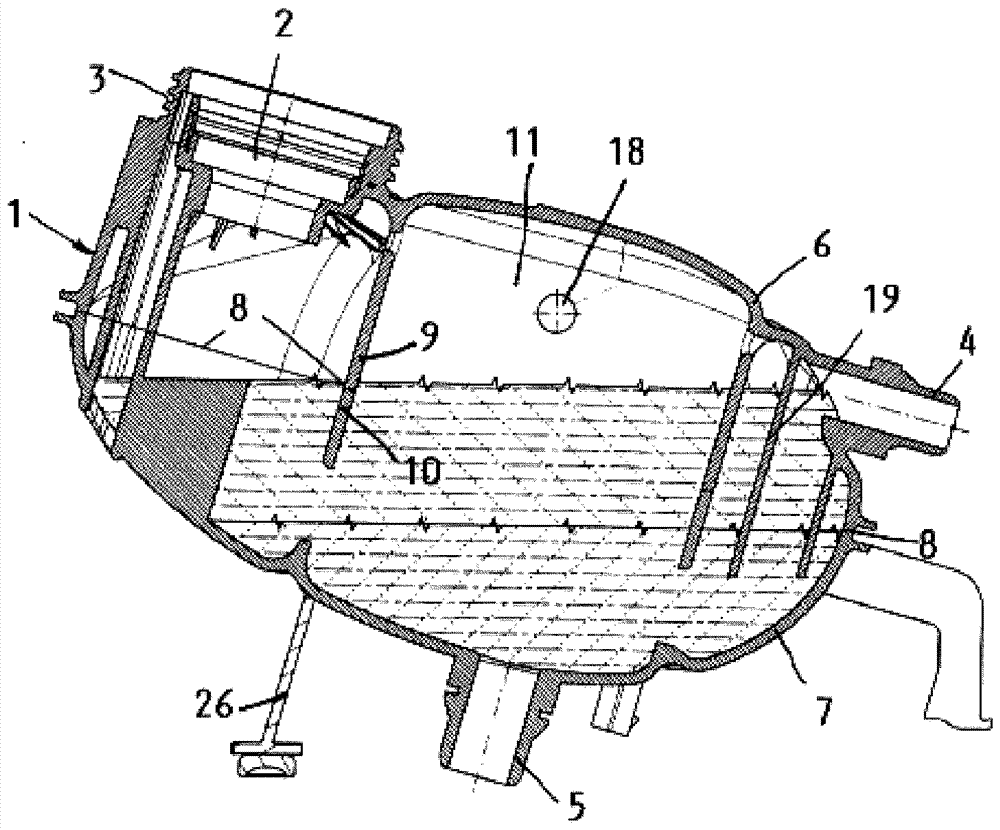

[0011] The compensating container or compensating container (Ausgleichsbehälter) 1 has an upper filling opening 2 with a connection piece 3 which is provided for receiving and locking a closure cap equipped with a pressure relief valve. For the hose connection to the cooling system of the internal combustion engine, the compensation container 1 also has upper and lower connecting lines 4 , 5 .

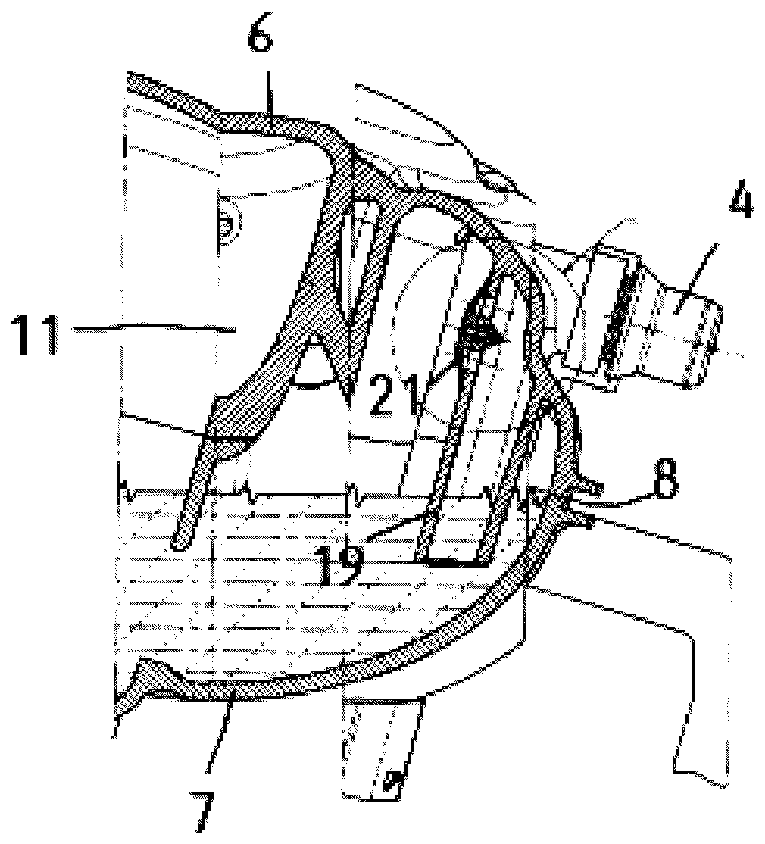

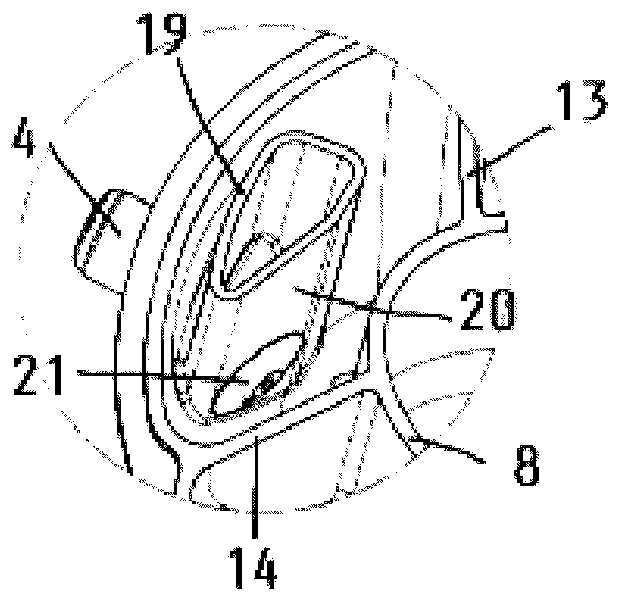

[0012] Due to the large temperature and pressure differences that occur in the cooling system, the compensating container 1 is subjected to high loads. Due to its design in the plastic injection molding process from two arched container shells 6 , 7 which are connected to one another via welding, and due to the resulting spherical or oval shape, it is possible at relatively low material costs The corresponding forces are absorbed without loss. Furthermore, the container housings 6 , 7 have annular inner walls 9 , 10 extending perpendicularly to the connecting surface 8 between them, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com