Stirring implement, stirring device and use thereof

The technology of a stirring device and agitator is applied in the field of agitating devices and agitators for mixing abrasives, which can solve the problems of waste, strong wear and a large amount, and achieve the effects of improving service life, reducing mechanical wear and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

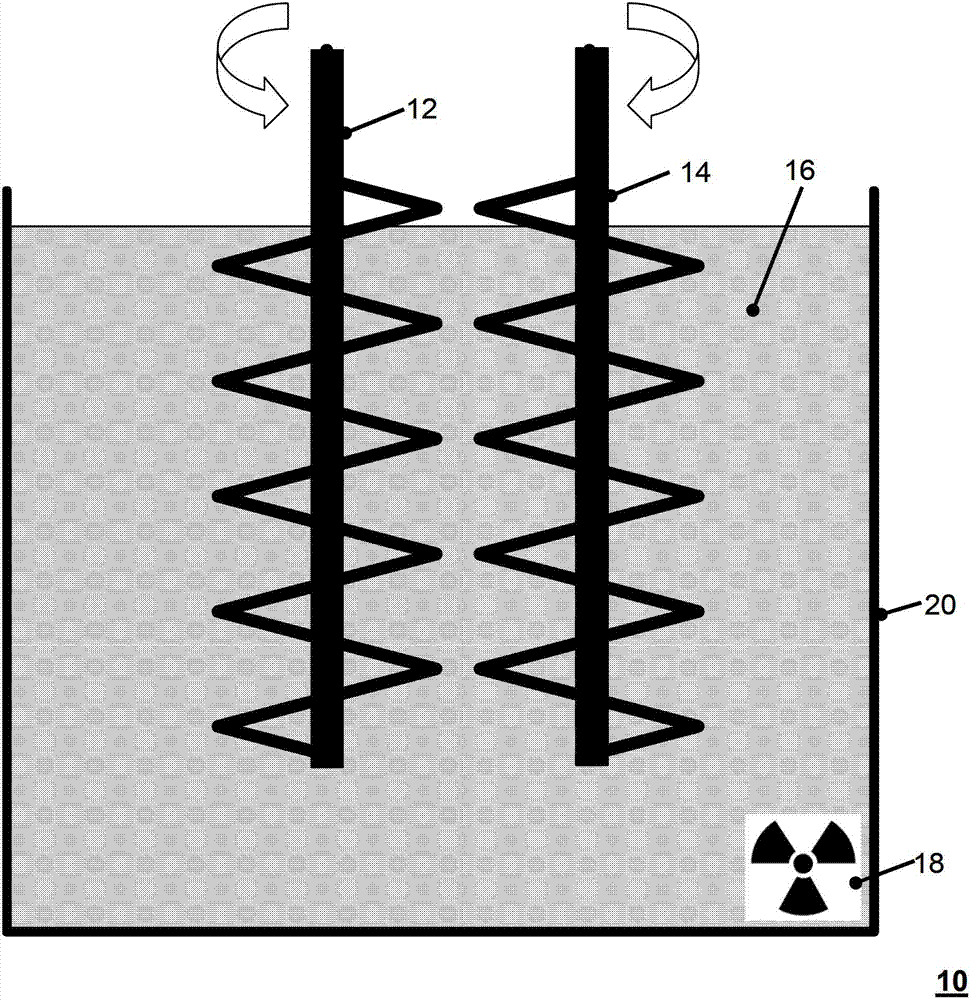

[0034] figure 1 Illustration 10 shows two counter-driven stirrers 12 , 14 in a stirrer container 20 . The stirring vessel is filled with a cement-water mixture to be stirred, which mixture is radioactive, as indicated by reference numeral 18 . Radioactive loading is achieved by mixing radioactive waste, which is safely stored in cement that sets later. The mixers 12 , 14 which come into contact with the cement-water mixture 16 are preferably cleaned after the respective mixing or stirring process. Ideally, however, this cleaning cycle is delayed as long as possible, ie not after every mixing process.

[0035] By coating the mixer with PEEK according to the invention, adhesion of cement or similar materials to be mixed on the mixing tools 12 , 14 is advantageously reduced, so that maintenance intervals are extended. The total amount of cement residues adhering to the mixer which are to be removed as radioactive waste produced during the individual cleaning cycles is thus adv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com