Sampling system

A technology of sampling system and sampling tank, which is applied in the field of sampling system and can solve problems such as complex structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

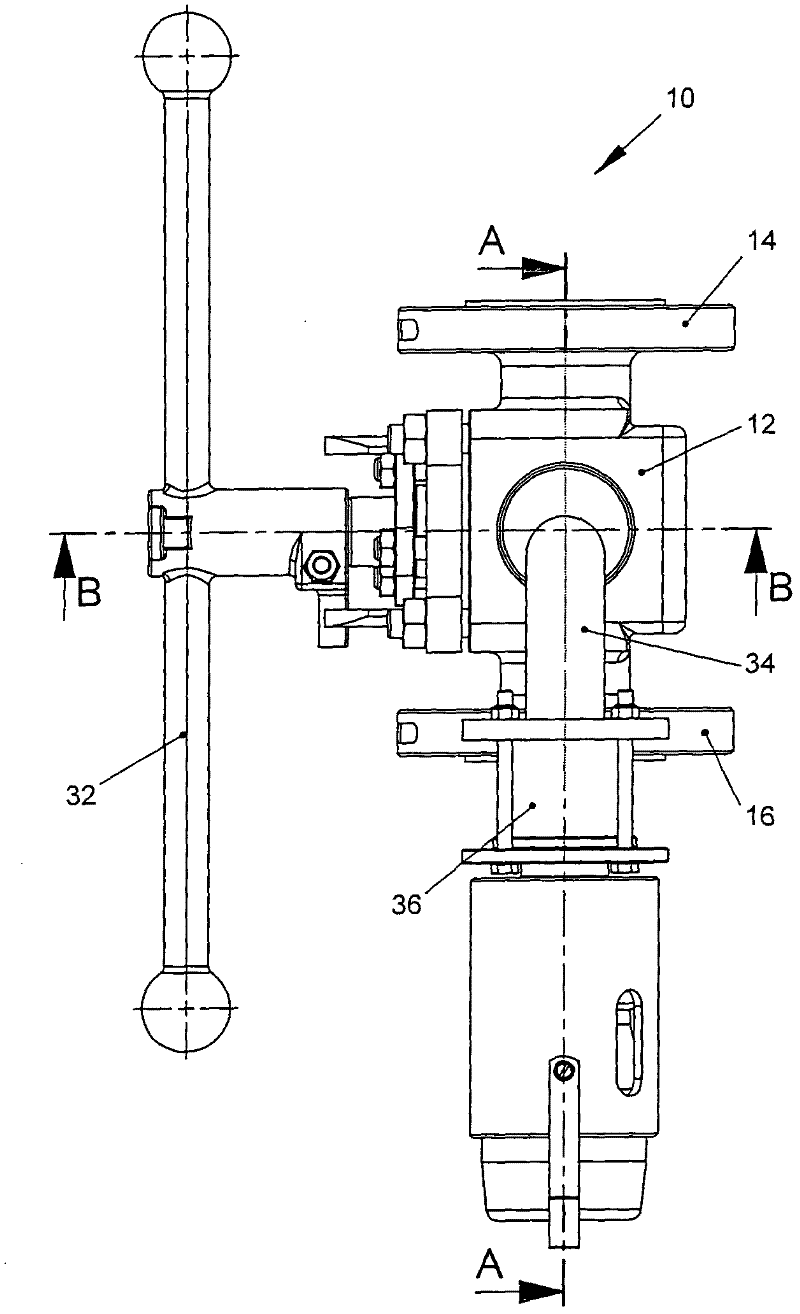

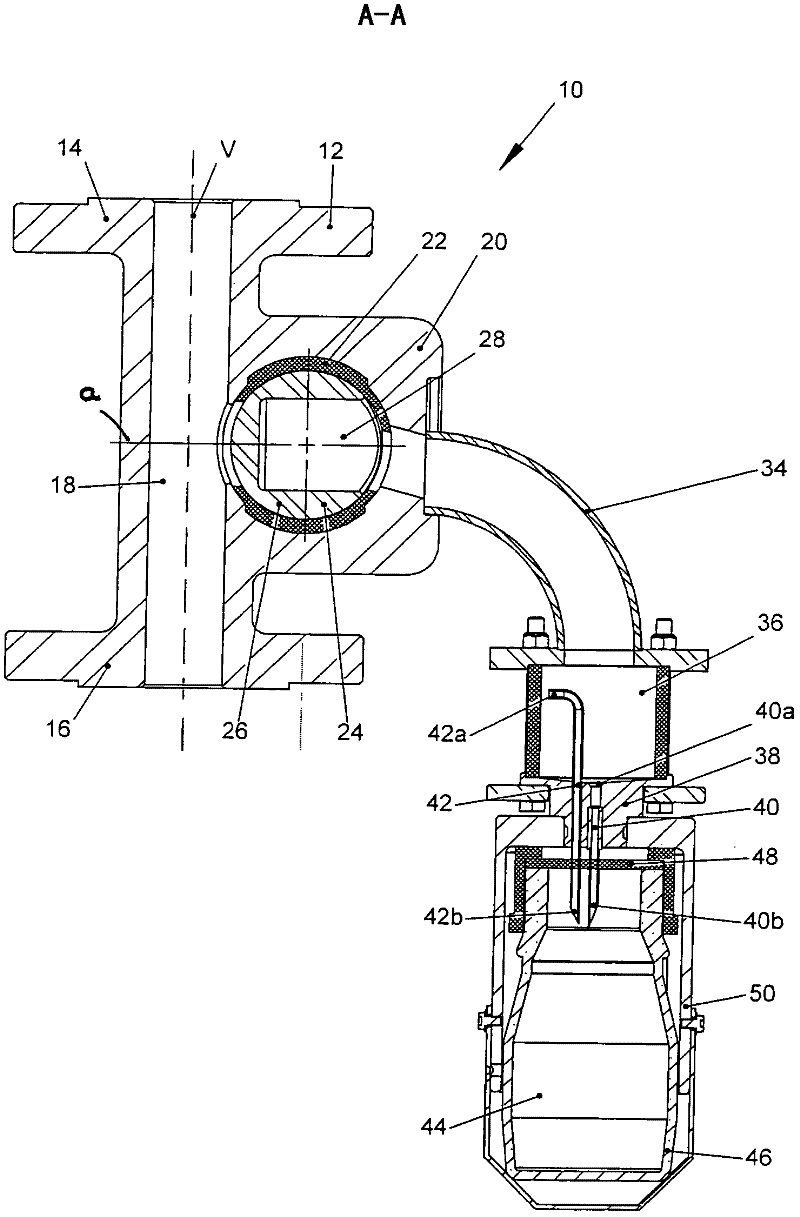

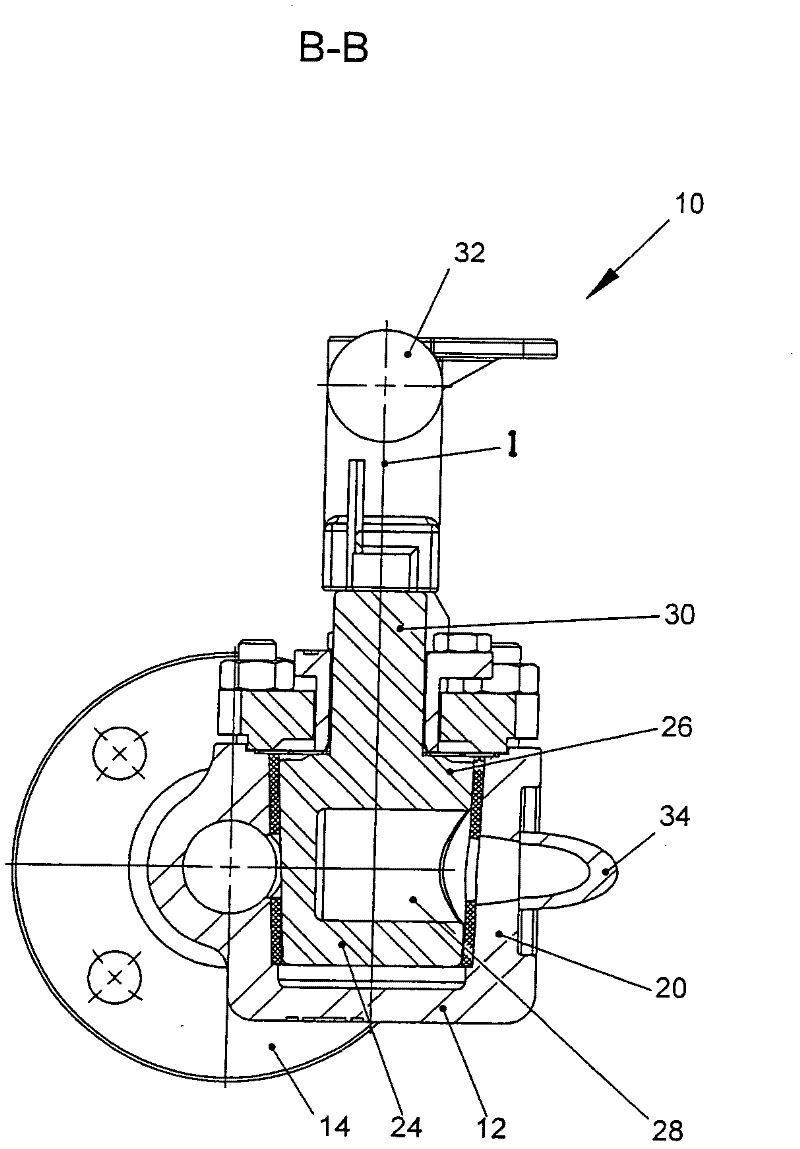

[0022] Figure 1 to Figure 3 Different views of the sampling system 10 are shown, wherein not all reference numbers are shown in all figures in order to simplify the illustration.

[0023] The sampling system 10 has a housing 12, which is substantially cylindrical, with a first connecting piece 14 and a second connecting piece 16, which are connected by a substantially cylindrical, connecting piece. The connecting cavities 18 of the axis v are connected. The first connection piece 14 and the second connection piece 16 can be respectively connected to a fluid flow conduit, so that the housing 12 becomes a part of the fluid flow conduit. The sampling system 10 is used in particular for sampling in lines through which liquids flow.

[0024] A connecting chamber 22 with a longitudinal axis a extends inside the housing 12 transversely to the connection axis v and connects the communicating chamber 18 with the third connecting part 20 . In particular, the connecting chamber 22 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com