LED radiator

A technology of light-emitting diodes and heat sinks, which is applied in the field of heat sinks, can solve problems such as weight gain and volume increase of lighting devices, and achieve the effects of enhancing natural convection, reducing weight, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

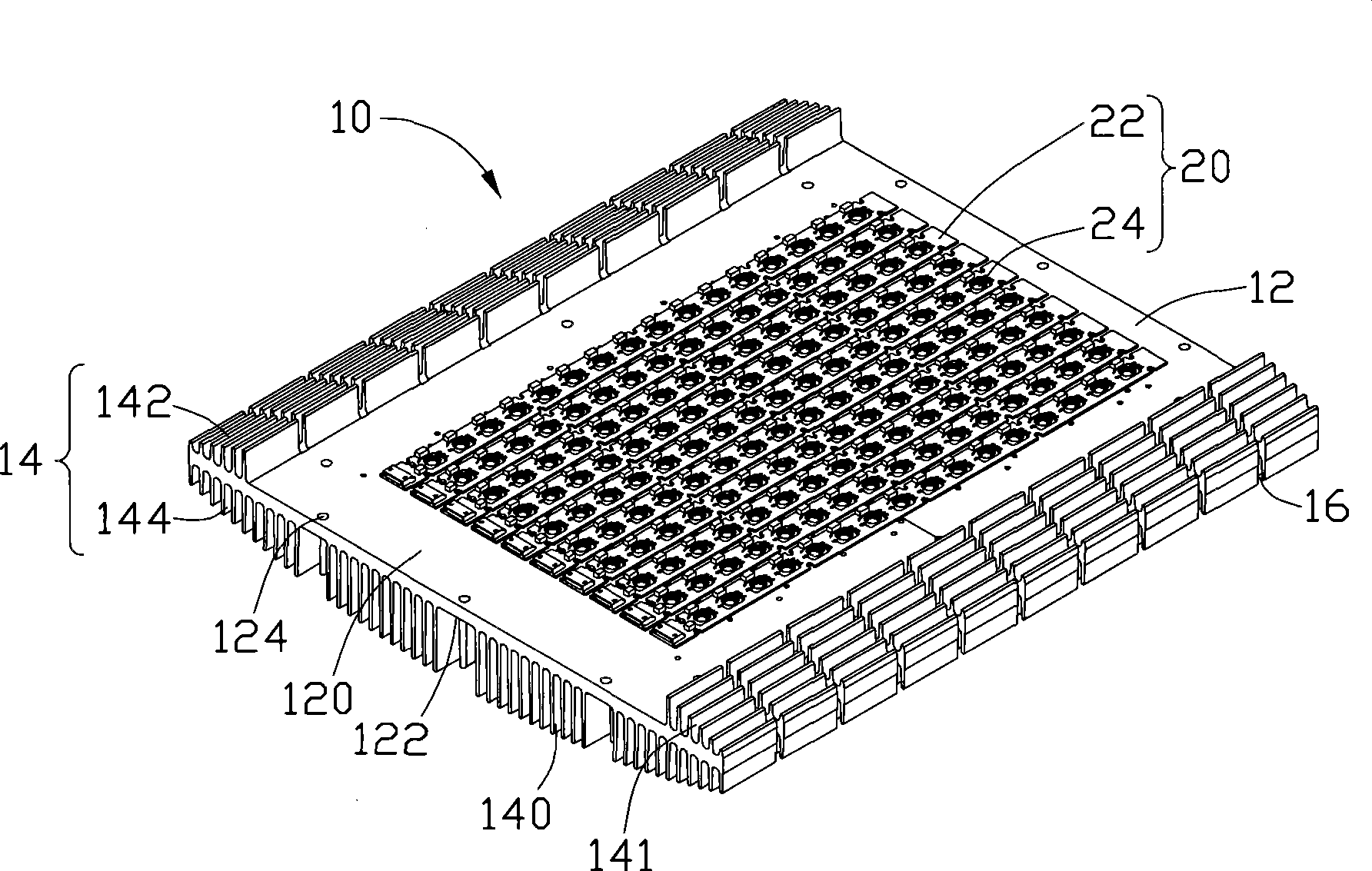

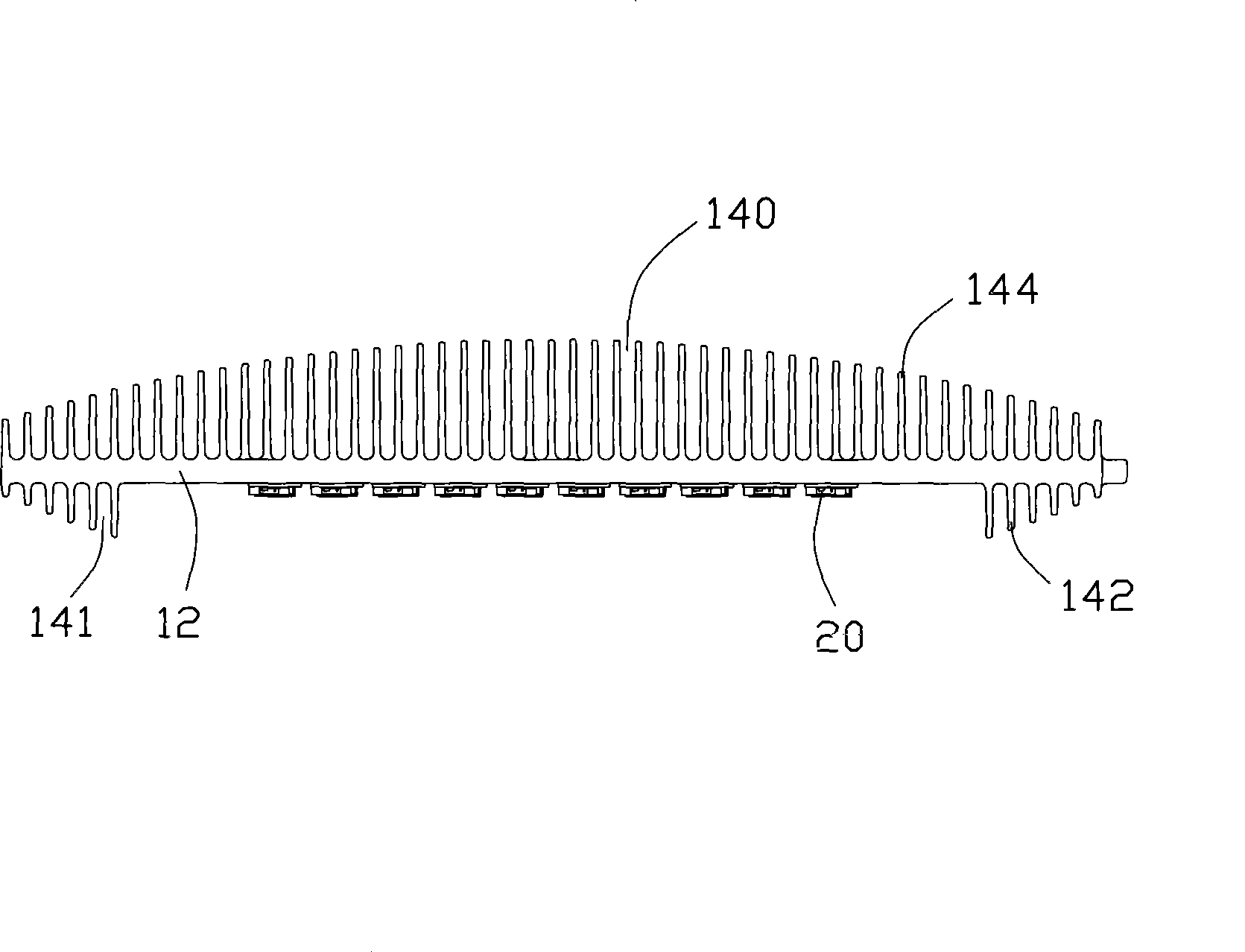

[0011] see Figure 1 to Figure 3 , is the light-emitting diode heat sink 10 in a preferred embodiment of the present invention, which is used to dissipate heat from the light-emitting diode module 20 . The LED module 20 is generally used as a light source of a lamp (not shown).

[0012] The light-emitting diode module 20 is closely attached to the bottom surface of the light-emitting diode heat sink 10, and includes a plurality of circuit boards 22 and a plurality of light-emitting diodes 24 that are parallel to each other. The circuit board 22 is electrically connected.

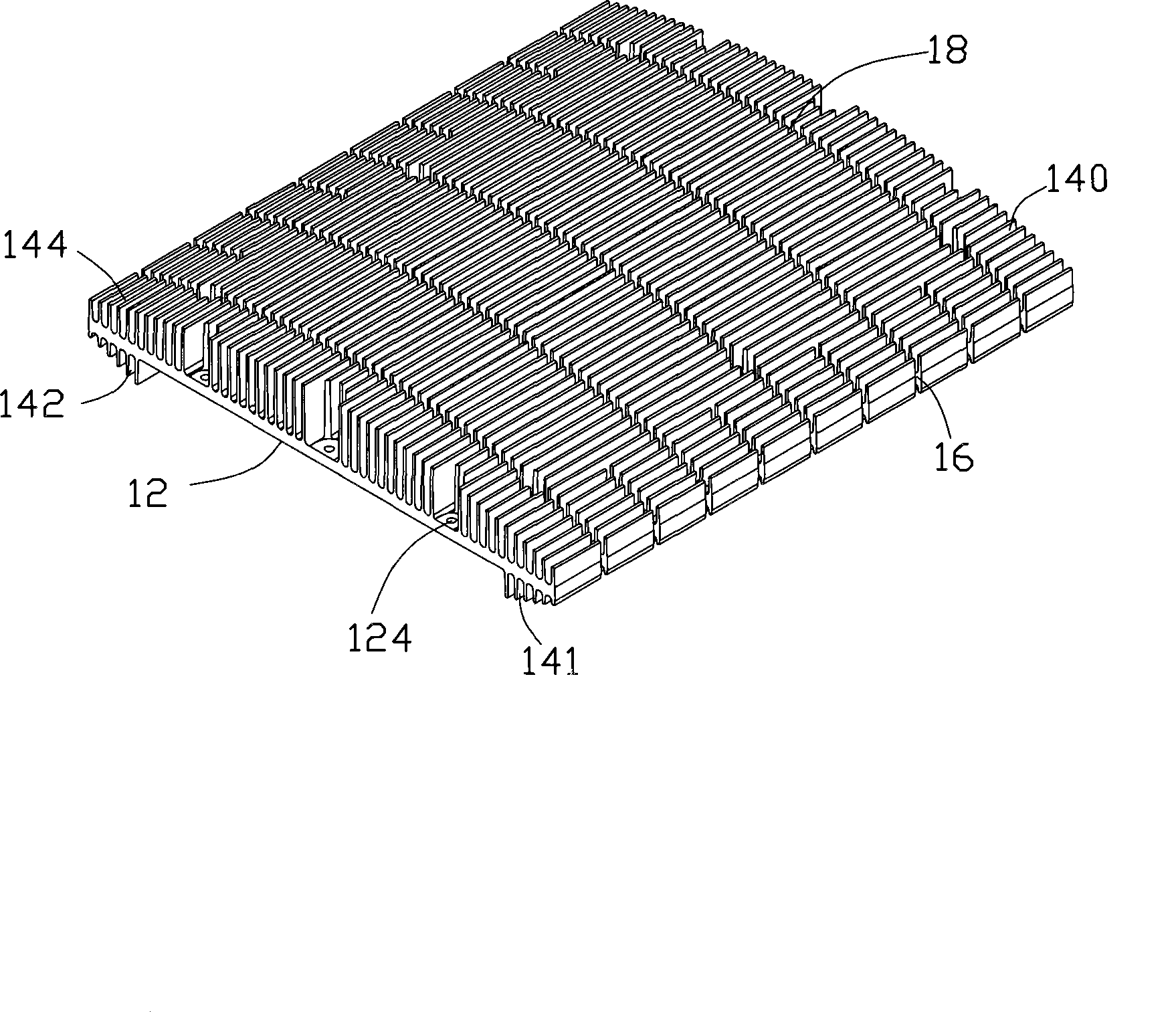

[0013] The LED heat sink 10 is made of a metal or alloy with high thermal conductivity, such as copper, aluminum or copper-aluminum alloy, and includes a substantially rectangular plate-shaped substrate 12 and a plurality of vertically extending from the surface of the substrate 12 . cooling fins 14 . The substrate 12 has a bottom surface 120 and a top surface 122 opposite to the bottom surface 120 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com