Single-surface glue water tape and making method thereof

A production method and glue technology, which are applied to coatings, hoses, mechanical equipment, etc., to achieve the effects of being conducive to environmental protection, dense coating, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

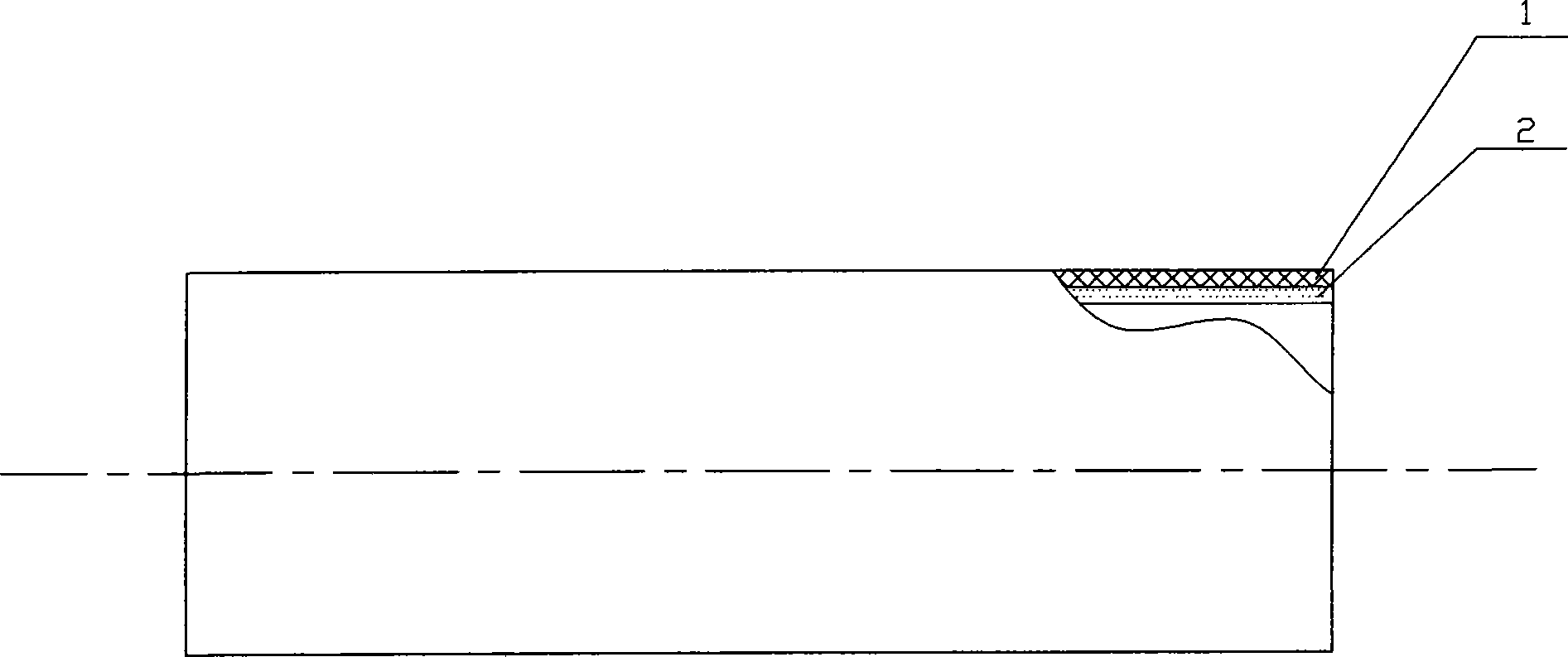

[0011] Example 1: First, use polyester yarn as warp and weft on a circular loom to weave a tubular fiber braided layer 1, then mix isocyanate and oligomer diol in a weight ratio of 1:0.6, as component A, amino-terminated poly Ether, liquid amine chain extender, filler and additives are used to form a slurry in parts by weight of 60:20:10:10 as the R component, and then the A component and the R component are fully mixed at a volume ratio of 1:0.8, At 60°C and a pressure of 12 MPa, use a spray gun to spray on the inner side of the fiber braided layer to form a polyurea elastomer coating 2; spray with a thickness of 0.5 mm and dry for 1 minute to obtain a single-sided adhesive tape.

example 2

[0012] Example 2: First, use high-strength aramid yarn as warp and weft on a circular loom to weave tubular fiber braided layer 1, then mix isocyanate and oligomer trihydric alcohol in a weight ratio of 1:0.7, as component A, Amino-terminated polyether, liquid amine chain extender, filler and additives are composed of slurry in parts by weight of 50:30:8:5, as the R component, and then the A component and the R component are fully mixed in a volume ratio of 1:1.2 After mixing, use a spray gun to spray on the inner side of the fiber braided layer at 65°C and a pressure of 14MPa to form a polyurea elastomer coating 2; spray with a thickness of 0.7mm and dry for 2 minutes to obtain a single-sided adhesive tape.

example 3

[0013] Example 3: First, use high-strength aramid yarn as warp and weft on a circular loom to weave a tubular fiber braided layer 1, then mix isocyanate and oligomer glycol in a weight ratio of 1:0.9, as component A, Amino-terminated polyether, liquid amine chain extender, filler and additives are composed of slurry in parts by weight of 55:35:10:5, as the R component, and then the A component and the R component are fully mixed in a volume ratio of 1:1. After mixing, use a spray gun to spray on the inner side of the fiber braided layer at 70°C and a pressure of 15 MPa to form a polyurea elastomer coating 2; spray with a thickness of 1.0 mm and dry for 1.5 minutes to obtain a single-sided adhesive tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com