Production facility and production process for 6A grade white steam filature

A technology of production process and production equipment, which is applied in the field of production equipment and production process of 6A white factory silk, can solve the problems such as difficulty in controlling the pressure and temperature of the cooking chamber, lack of monitoring in the production process of white factory silk, poor product quality stability, etc. Achieve the effects of improving the unwinding rate and cleanliness index, reducing the middle and inner layers, and ensuring the quality of the cocoon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

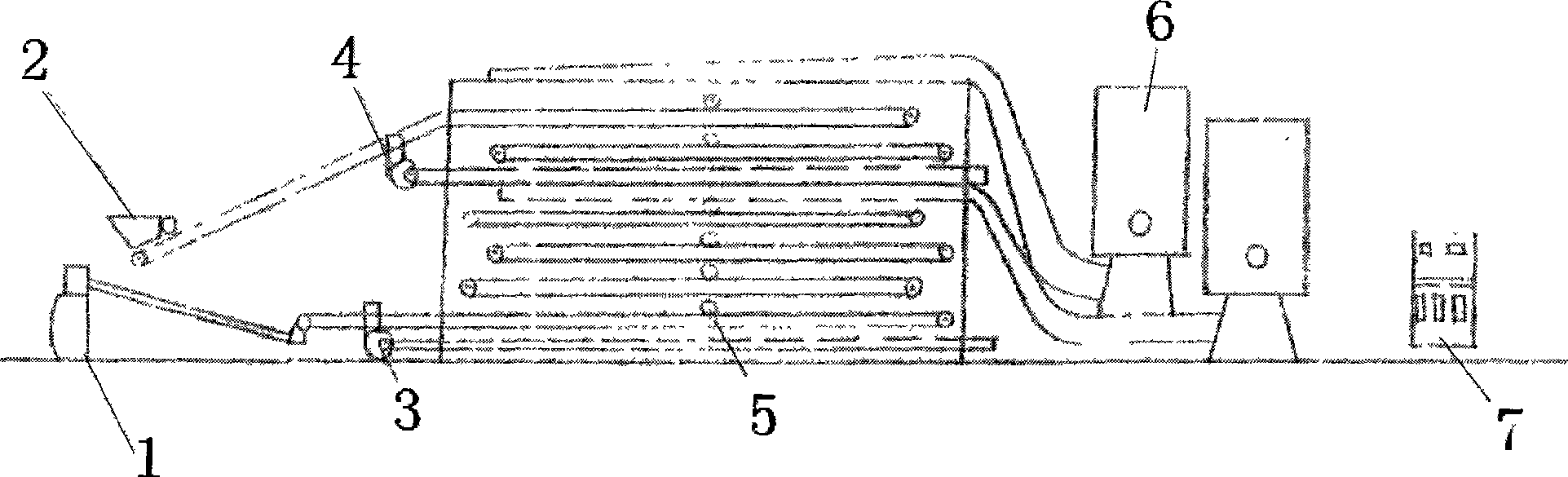

[0021] A kind of production equipment of 6A white factory silk, according to the sequence of the production process, it includes cocoon drying equipment, cocoon sorting equipment, cocoon cooking equipment, self-reeling equipment, re-shaking equipment, etc., and the cocoon drying equipment is equipped with fresh cocoon water Rate detection device.

[0022] The cocoon drying equipment includes a main body of a cocoon drying machine, a packaging machine 1, an automatic cocoon laying machine 2, a dehumidification fan 3, a high temperature dehumidification fan 4, etc. are connected to one side of the cocoon drying machine main body. The other side of the main body of the cocoon machine is connected with an air furnace 6 and an electric control box 7 , and a moisture content detection device is installed inside the main body of the cocoon drying machine;

[0023] The cocoon-drying equipment adopts the design of Sichuan West Sichuan Institute of Mechanics and Electronics, and the CL-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com