Vacuum multifunctional continuous film coating apparatus

A coating device and vacuum coating technology are applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., which can solve the problems of lengthening the process flow, reducing processing efficiency, and high manufacturing cost, so as to shorten the process flow and ensure Film quality, effect of preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

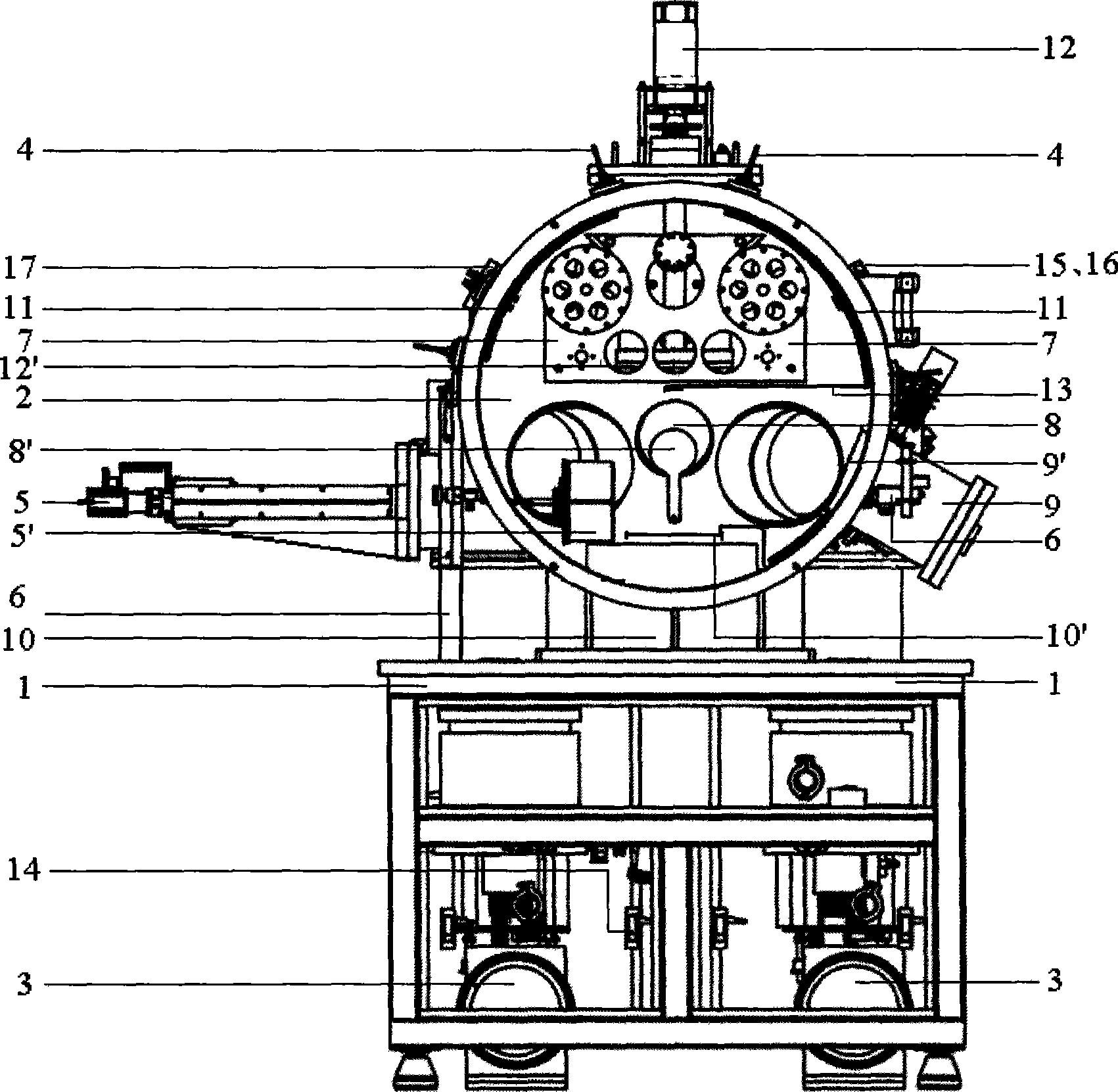

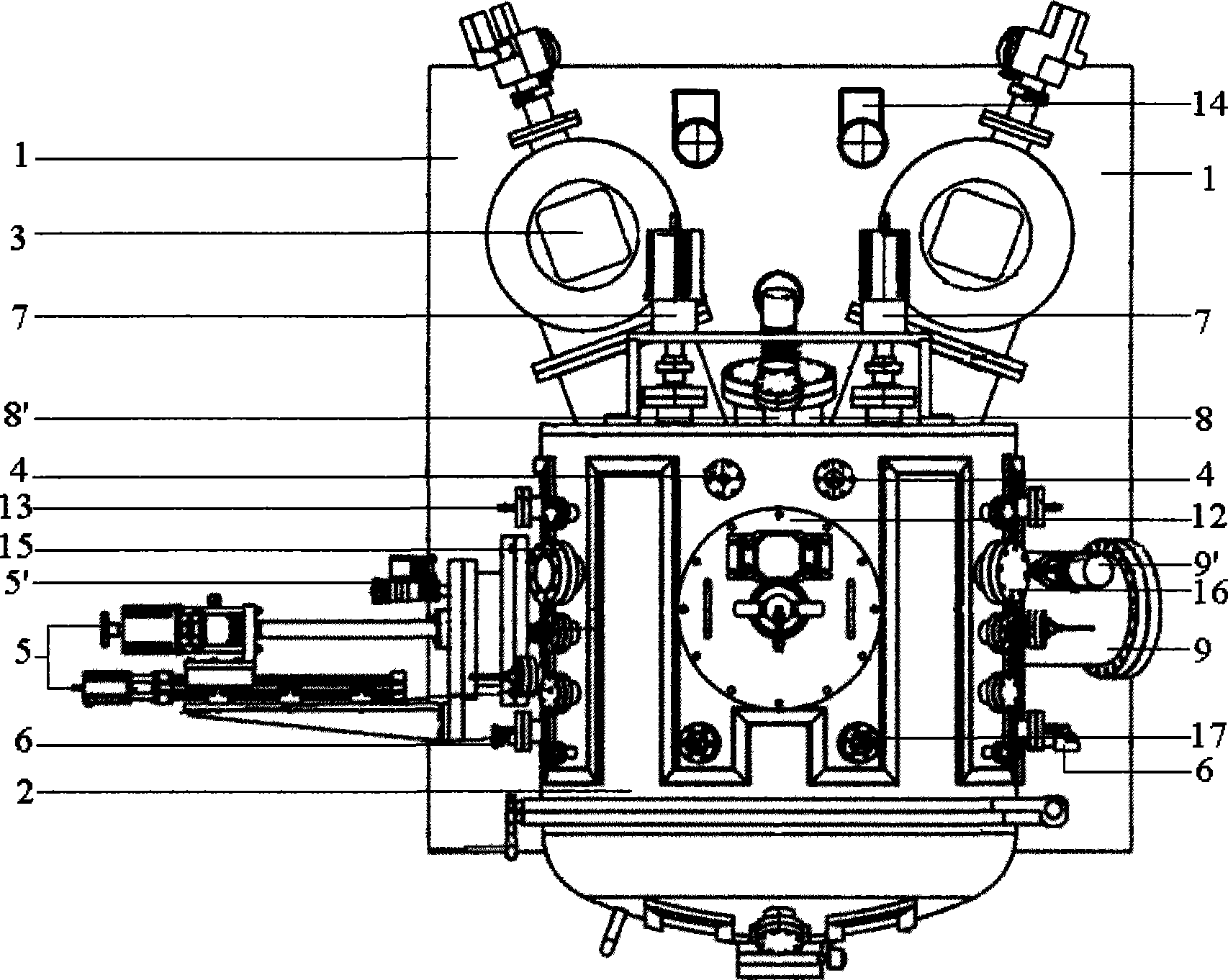

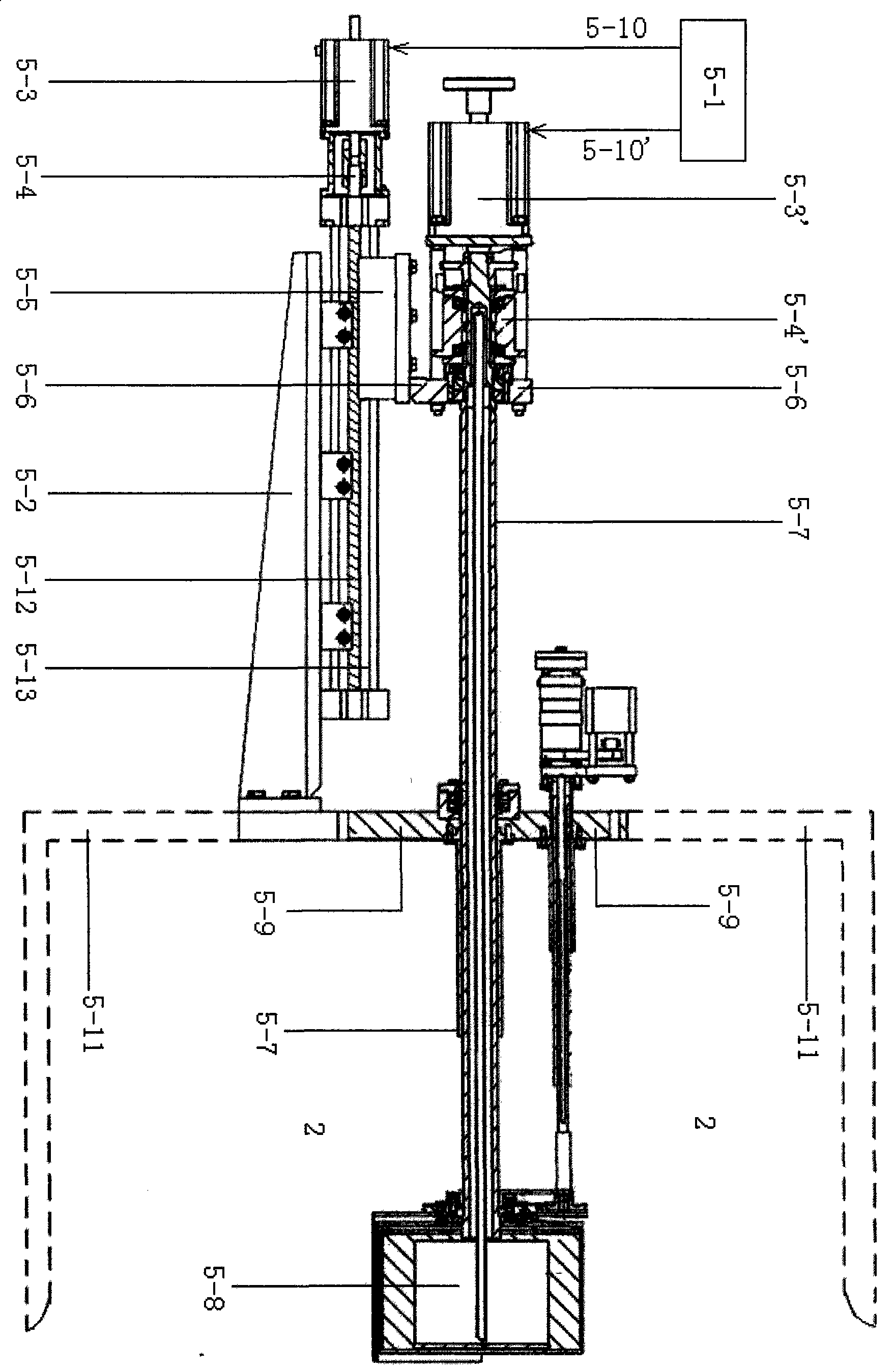

[0033] Such as figure 1 and figure 2 As shown, the high-vacuum multifunctional ion beam sputtering and electron beam evaporation continuous coating device of the present invention consists of a rack platform 1, a vacuum coating chamber 2, a pumping 3, a vacuum measurement 4, a swing / moving sputtering target platform 5, Swing / moving sputtering target platform baffle 5', gas path 6, constant tension reversible winding 7, ion beam sputtering source 8, ion beam sputtering source baffle 8', ion beam auxiliary enhancement / cleaning source 9, Ion beam assisted strengthening / cleaning source baffle 9', electron beam evaporation source 10, electron beam evaporation source baffle 10', baking 11, water cooling / heating turntable 12, water cooling / heating turntable baffle 12' and control the above The electric control of the power switch of each unit (which can be controlled separately by separate control cabinets, or all the electric control parts can be concentrated in the overall contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com