Method for preparing flexible non-weaving suction wave material and product thereof

A wave-absorbing material and non-woven technology, which is applied in the field of preparation of flexible non-woven wave-absorbing materials and its products, can solve the problems that the relevant content of the preparation method has not been disclosed, and achieve industrialization with easy implementation, low cost, and easy laying volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

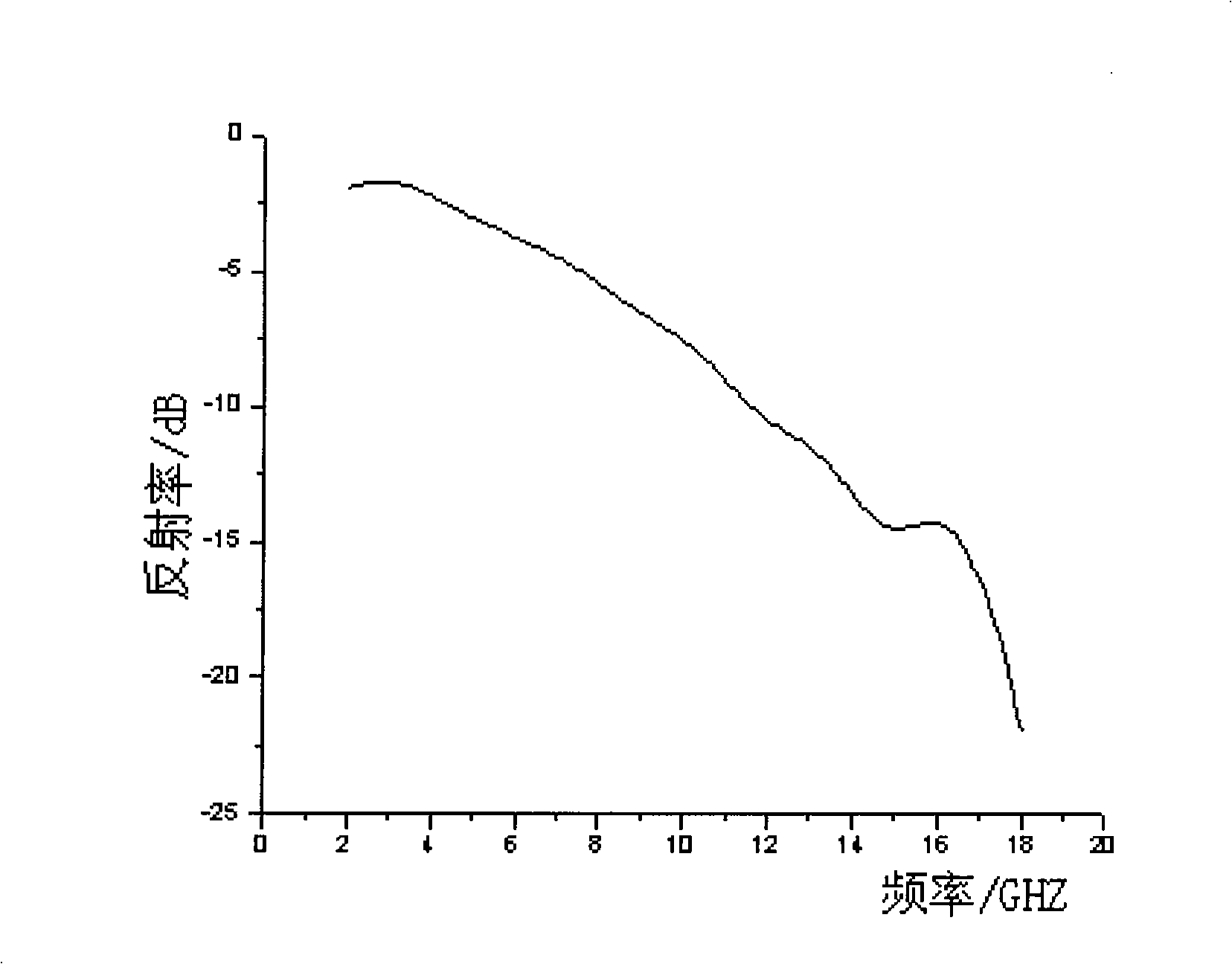

Image

Examples

preparation example Construction

[0022] The preparation method of the flexible nonwoven wave-absorbing material of the present invention mainly includes five steps: (1) matching of fiber raw materials; (2) fiber mixing; (3) carding into a web; (4) laying the web; (5) reinforcement.

[0023] According to the existing technology, there are mainly two technical problems to be solved: fiber selection and mixing carding, and process parameter setting of wave-absorbing materials.

[0024] The preparation method of the present invention requires the selected fiber material to have properties such as wave-absorbing performance, sun-resistant, mildew-proof and moth-proof. The present invention selects chopped carbon fiber with wave-absorbing performance, single filament diameter of 5-10 μm, length of 30-50 mm, polyester fiber: linear density of 1.5-3.0 dtex, length of 30-60 mm. Carbon fiber and polyester fiber are selected according to a certain ratio and selected according to a certain ratio.

[0025] The key probl...

specific Embodiment

[0030] Fiber raw material: chopped carbon fiber, monofilament diameter 5-10μm, length 30-50mm, polyester fiber: linear density 1.5-3.0dtex, length 30-60mm.

example 1

[0032] (1) Selection of fiber raw materials: chopped carbon fiber monofilament diameter 5, length 40mm, mass percentage 5%; polyester fiber: linear density 1.5dtex, length 60mm, mass percentage 95%.

[0033] (2) Fiber mixing: first perform "false blending" and then mix.

[0034] (3) Carding into a web: the carding machine combs into a web.

[0035] (4) Laying: cross-lapping.

[0036] (5) Reinforcement: Send the laid fiber net into the needle loom for pre-punching and main stabbing.

[0037] Product Quantitative 100g / m 2 , thickness 3.5mm, acupuncture density 800 pricks / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com